Filter News

Area of Research

News Topics

- (-) Composites (5)

- (-) Fossil Energy (4)

- 3-D Printing/Advanced Manufacturing (34)

- Advanced Reactors (8)

- Artificial Intelligence (43)

- Big Data (21)

- Bioenergy (48)

- Biology (56)

- Biomedical (28)

- Biotechnology (10)

- Buildings (17)

- Chemical Sciences (21)

- Clean Water (14)

- Climate Change (46)

- Computer Science (80)

- Coronavirus (17)

- Critical Materials (1)

- Cybersecurity (14)

- Decarbonization (43)

- Education (1)

- Emergency (2)

- Energy Storage (28)

- Environment (100)

- Exascale Computing (24)

- Frontier (23)

- Fusion (28)

- Grid (23)

- High-Performance Computing (42)

- Hydropower (5)

- Isotopes (25)

- ITER (2)

- Machine Learning (21)

- Materials (39)

- Materials Science (41)

- Mathematics (5)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (33)

- Net Zero (8)

- Neutron Science (46)

- Nuclear Energy (52)

- Partnerships (13)

- Physics (26)

- Polymers (7)

- Quantum Computing (17)

- Quantum Science (27)

- Renewable Energy (1)

- Security (10)

- Simulation (29)

- Software (1)

- Space Exploration (12)

- Summit (30)

- Sustainable Energy (42)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

Scientists at Oak Ridge National Laboratory and six other Department of Energy national laboratories have developed a United States-based perspective for achieving net-zero carbon emissions.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

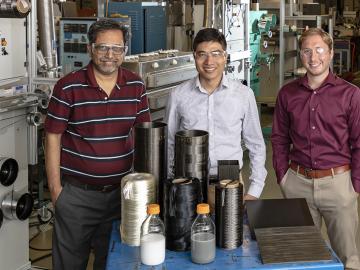

SkyNano, an Innovation Crossroads alumnus, held a ribbon-cutting for their new facility. SkyNano exemplifies using DOE resources to build a successful clean energy company, making valuable carbon nanotubes from waste CO2.

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.

Researchers at ORNL are extending the boundaries of composite-based materials used in additive manufacturing, or AM. ORNL is working with industrial partners who are exploring AM, also known as 3D printing, as a path to higher production levels and fewer supply chain interruptions.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

Natural gas furnaces not only heat your home, they also produce a lot of pollution. Even modern high-efficiency condensing furnaces produce significant amounts of corrosive acidic condensation and unhealthy levels of nitrogen oxides

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

Carbon fiber composites—lightweight and strong—are great structural materials for automobiles, aircraft and other transportation vehicles. They consist of a polymer matrix, such as epoxy, into which reinforcing carbon fibers have been embedded. Because of differences in the mecha...