Filter News

Area of Research

- (-) Computational Chemistry (5)

- (-) Fusion Energy (17)

- Advanced Manufacturing (34)

- Biological Systems (18)

- Biology and Environment (177)

- Biology and Soft Matter (5)

- Building Technologies (12)

- Chemical and Engineering Materials (4)

- Chemistry and Physics at Interfaces (11)

- Clean Energy (522)

- Climate and Environmental Systems (14)

- Computational Biology (6)

- Computational Engineering (5)

- Computer Science (19)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (14)

- Energy Sciences (5)

- Fossil Energy (3)

- Fuel Cycle Science and Technology (3)

- Functional Materials for Energy (16)

- Fusion and Fission (54)

- Geographic Information Science and Technology (3)

- Isotope Development and Production (3)

- Isotopes (35)

- Materials (433)

- Materials Characterization (2)

- Materials for Computing (36)

- Materials Synthesis from Atoms to Systems (13)

- Materials Under Extremes (12)

- Mathematics (1)

- National Security (79)

- Neutron Data Analysis and Visualization (4)

- Neutron Science (190)

- Nuclear Science and Technology (74)

- Nuclear Systems Modeling, Simulation and Validation (3)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (4)

- Quantum information Science (9)

- Reactor Technology (1)

- Renewable Energy (4)

- Sensors and Controls (5)

- Supercomputing (311)

- Transportation Systems (11)

News Type

Media Contacts

Kathy McCarthy has been named director of the US ITER Project Office at the Department of Energy’s Oak Ridge National Laboratory, effective March 2020.

The U.S. Department of Energy announced funding for 12 projects with private industry to enable collaboration with DOE national laboratories on overcoming challenges in fusion energy development.

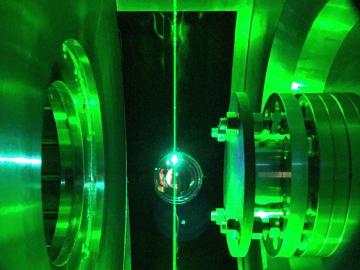

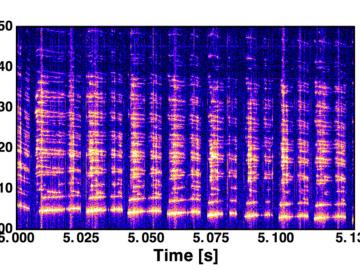

In a recent study, researchers at Oak Ridge National Laboratory performed experiments in a prototype fusion reactor materials testing facility to develop a method that uses microwaves to raise the plasma’s temperature closer to the extreme values

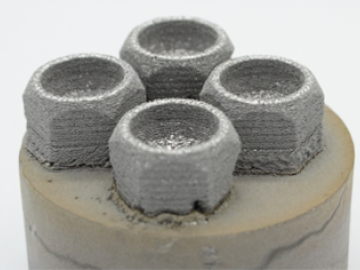

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.

When it’s up and running, the ITER fusion reactor will be very big and very hot, with more than 800 cubic meters of hydrogen plasma reaching 170 million degrees centigrade. The systems that fuel and control it, on the other hand, will be small and very cold. Pellets of frozen gas will be shot int...