Filter News

Area of Research

- (-) Advanced Manufacturing (34)

- (-) Energy Sciences (5)

- Biological Systems (18)

- Biology and Environment (177)

- Biology and Soft Matter (5)

- Building Technologies (12)

- Chemical and Engineering Materials (4)

- Chemistry and Physics at Interfaces (11)

- Clean Energy (522)

- Climate and Environmental Systems (14)

- Computational Biology (6)

- Computational Chemistry (5)

- Computational Engineering (5)

- Computer Science (19)

- Data (1)

- Earth Sciences (1)

- Electricity and Smart Grid (3)

- Energy Frontier Research Centers (14)

- Fossil Energy (3)

- Fuel Cycle Science and Technology (3)

- Functional Materials for Energy (16)

- Fusion and Fission (54)

- Fusion Energy (17)

- Geographic Information Science and Technology (3)

- Isotope Development and Production (3)

- Isotopes (35)

- Materials (432)

- Materials Characterization (2)

- Materials for Computing (36)

- Materials Synthesis from Atoms to Systems (13)

- Materials Under Extremes (12)

- Mathematics (1)

- National Security (79)

- Neutron Data Analysis and Visualization (4)

- Neutron Science (190)

- Nuclear Science and Technology (74)

- Nuclear Systems Modeling, Simulation and Validation (3)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (4)

- Quantum information Science (9)

- Reactor Technology (1)

- Renewable Energy (4)

- Sensors and Controls (5)

- Supercomputing (311)

- Transportation Systems (11)

News Topics

- 3-D Printing/Advanced Manufacturing (22)

- Advanced Reactors (1)

- Artificial Intelligence (1)

- Bioenergy (1)

- Composites (3)

- Computer Science (1)

- Cybersecurity (1)

- Energy Storage (1)

- Fusion (1)

- Machine Learning (1)

- Materials (6)

- Materials Science (5)

- Neutron Science (2)

- Nuclear Energy (2)

- Space Exploration (1)

- Sustainable Energy (6)

- Transformational Challenge Reactor (1)

Media Contacts

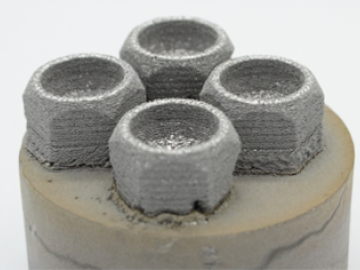

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

OAK RIDGE, Tenn., May 8, 2019—Oak Ridge National Laboratory and Lincoln Electric (NASDAQ: LECO) announced their continued collaboration on large-scale, robotic additive manufacturing technology at the Department of Energy’s Advanced Manufacturing InnovationXLab Summit.

A novel additive manufacturing method developed by researchers at Oak Ridge National Laboratory could be a promising alternative for low-cost, high-quality production of large-scale metal parts with less material waste.

Two leaders in US manufacturing innovation, Thomas Kurfess and Scott Smith, are joining the Department of Energy’s Oak Ridge National Laboratory to support its pioneering research in advanced manufacturing.

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

While serving in Kandahar, Afghanistan, U.S. Navy construction mechanic Matthew Sallas may not have imagined where his experience would take him next. But researchers at Oak Ridge National Laboratory certainly had the future in mind as they were creating programs to train men and wome...

Scientists at Oak Ridge National Laboratory are using the precision of an electron beam to instantly adhere cathode coatings for lithium-ion batteries—a leap in efficiency that saves energy, reduces production and capital costs, and eliminates the use of toxic solvents.

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity from slow or shallow water flo...

A 3D printed trim-and-drill tool, developed by researchers at the Department of Energy’s Oak Ridge National Laboratory to be evaluated at The Boeing Company, has received the title of largest solid 3D printed item by Guinness World Records. ORNL printed the...