Filter News

Area of Research

- Biology and Environment (30)

- Biology and Soft Matter (1)

- Clean Energy (37)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (2)

- Materials (7)

- Materials for Computing (1)

- National Security (3)

- Neutron Science (3)

- Nuclear Science and Technology (1)

- Supercomputing (7)

- Transportation Systems (1)

News Topics

- (-) Biotechnology (21)

- (-) Decarbonization (74)

- 3-D Printing/Advanced Manufacturing (116)

- Advanced Reactors (34)

- Artificial Intelligence (87)

- Big Data (50)

- Bioenergy (88)

- Biology (96)

- Biomedical (58)

- Buildings (54)

- Chemical Sciences (59)

- Clean Water (29)

- Climate Change (94)

- Composites (25)

- Computer Science (184)

- Coronavirus (46)

- Critical Materials (24)

- Cybersecurity (35)

- Education (3)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (107)

- Environment (192)

- Exascale Computing (36)

- Fossil Energy (5)

- Frontier (41)

- Fusion (53)

- Grid (61)

- High-Performance Computing (83)

- Hydropower (11)

- Irradiation (3)

- Isotopes (47)

- ITER (7)

- Machine Learning (46)

- Materials (140)

- Materials Science (134)

- Mathematics (6)

- Mercury (12)

- Microelectronics (2)

- Microscopy (50)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (59)

- Net Zero (12)

- Neutron Science (129)

- Nuclear Energy (105)

- Partnerships (40)

- Physics (59)

- Polymers (31)

- Quantum Computing (31)

- Quantum Science (66)

- Renewable Energy (2)

- Security (24)

- Simulation (45)

- Software (1)

- Space Exploration (24)

- Statistics (3)

- Summit (57)

- Sustainable Energy (120)

- Transformational Challenge Reactor (7)

- Transportation (93)

Media Contacts

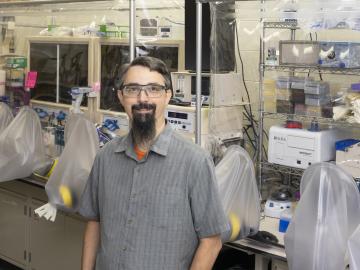

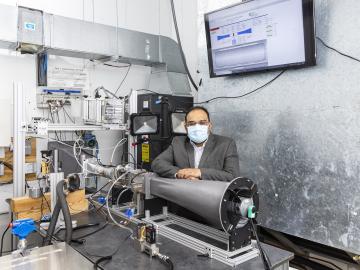

As a metabolic engineer at Oak Ridge National Laboratory, Adam Guss modifies microbes to perform the diverse processes needed to make sustainable biofuels and bioproducts.

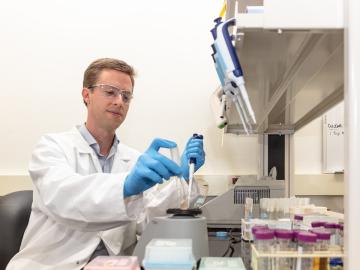

David Sholl has come to the U.S. Department of Energy’s Oak Ridge National Laboratory with a wealth of scientific expertise and a personal mission: hasten the development and deployment of decarbonization solutions for the nation’s energy system.

In a step toward increasing the cost-effectiveness of renewable biofuels and bioproducts, scientists at ORNL discovered a microbial enzyme that degrades tough-to-break bonds in lignin, a waste product of biorefineries.

Scientists at ORNL have discovered a single gene that simultaneously boosts plant growth and tolerance for stresses such as drought and salt, all while tackling the root cause of climate change by enabling plants to pull more carbon dioxide from the atmosphere.

A research team led by Oak Ridge National Laboratory bioengineered a microbe to efficiently turn waste into itaconic acid, an industrial chemical used in plastics and paints.

When Kashif Nawaz looks at a satellite map of the U.S., he sees millions of buildings that could hold a potential solution for the capture of carbon dioxide, a plentiful gas that can be harmful when excessive amounts are released into the atmosphere, raising the Earth’s temperature.

From soda bottles to car bumpers to piping, electronics, and packaging, plastics have become a ubiquitous part of our lives.

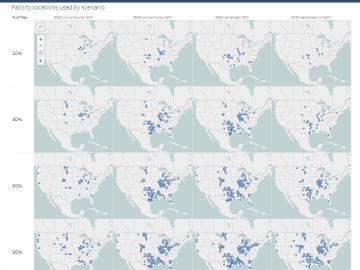

The combination of bioenergy with carbon capture and storage could cost-effectively sequester hundreds of millions of metric tons per year of carbon dioxide in the United States, making it a competitive solution for carbon management, according to a new analysis by ORNL scientists.

ORNL scientists have modified a single microbe to simultaneously digest five of the most abundant components of lignocellulosic biomass, a big step forward in the development of a cost-effective biochemical conversion process to turn plants into

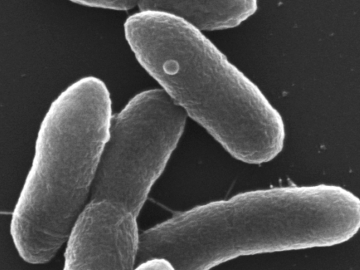

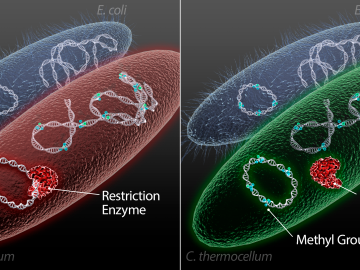

Scientists at the US Department of Energy’s Oak Ridge National Laboratory have demonstrated a method to insert genes into a variety of microorganisms that previously would not accept foreign DNA, with the goal of creating custom microbes to break down plants for bioenergy.