Oak Ridge National Laboratory (ORNL) researchers are working with the US Department of Energy (DOE), industry, and academia to develop new bioenergy solutions. ORNL is leading the way in advancing catalysts and systems for next generation bioproducts and biofuels. These ORNL innovations include a catalytic system for cost-effective conversion of ethanol to biofuels.

Cost-Effective and Market-Responsive Ethanol to Jet Fuel Technology

Technology Summary:

Ethanol To Jet fuel (ETJ) is a promising pathway to produce biofuels and to decarbonize the aviation sector due to the availability of resources such as:

- Current infrastructure for fuel ethanol production (~29B gallons/year globally) at deployment scale,

- Multiple varieties of sugar/starch and lignocellulosic feedstocks available, and

- Emerging opportunities in alcohol synthesis from industrial waste gases and CO2.

Industry seeks new ETJ technologies to lower the jet fuel production cost, which is one of the major barriers for large-scale deployment of Sustainable Aviation Fuels (SAFs). ORNL Researchers have developed a low-cost groundbreaking ETJ technology to address such barrier.

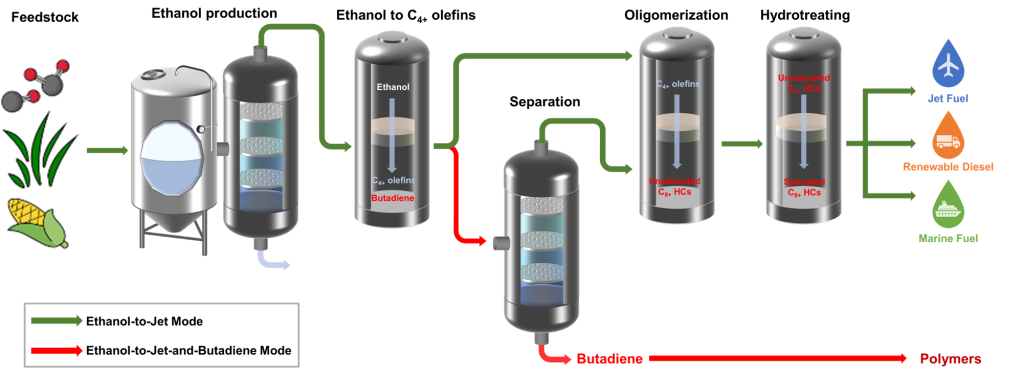

The ORNL technology comprises one-step conversion of ethanol to C4+ olefins (ETO), olefin oligomerization, and hydrogenation (Scheme 1). The process can be operated as either an ETJ mode (only fuel products) or an ethanol-to-jet-and-butadiene (ETJB) mode. The ETJ mode produces a high yield of paraffinic-type jet and diesel blends, and this catalytic system allows these two fractions to be tuned for the desired product composition. The ETJB mode produces both liquid fuels and 1,3-butadiene and the butadiene:fuels ratio can be adjusted by tuning the operation conditions. The entire system offers process flexibility to be responsive as future market evolves and changes.

Advantages and Benefits:

- Fewer conversion steps and lower CapEx and OpEx compared to ethylene-based ETJ. Results in ~37% reduction in ethanol upgrading cost.

- With the ETO step slightly exothermic, the process provides an advantage for scaled production.

- High yield of sustainable aviation fuel or renewable diesel. This system offers the highest olefin selectivity (>90% C4+ olefins, and >95% total olefins) among all one-step ETO catalysts.

- Flexible process with tunable operation mode for fuels and commodity chemicals. The high tunability of C4/C5+ olefins ratio offers a wide spectrum of olefin compositions for either jet or diesel production.

Tunable operation to target either fuel alone or fuel with 1,3-butadiene

- Flexible feedstock options such as ethanol, aqueous ethanol, or mixed alcohols.

- Robust to many impurities from upstream fermentation steps.

- Improved catalyst stability and activity (lower operation temperature) compared to other ETO catalysts.

Applications:

- Production of SAF and renewable diesel.

- Conversion of ethanol to other value-added chemicals.

State of Development:

R&D to Demonstration and Lab Scale Production

Intellectual Property:

US Patent Application 63/141,996, entitled “Methods and Catalysts for Alcohol Conversion,” filed on January 27, 2021. (ID Nos. 202004716/4717)

US Patent Application 63/288,084, entitled “A scalable and environmentally friendly synthesis method for highly dispersed metals encapsulated within zeolites,” filed on December 10, 2021. (ID No. 202104986)

Related Publications:

Junyan Zhang, Eunji Yoo, Brian H. Davison, Dongxia Liu, Joshua A. Schaidle, Ling Tao* and Zhenglong Li*. Towards cost-competitive middle distillate fuels from ethanol within a market-flexible biorefinery concept. Green Chem., 2021,23, 9534-9548.

Junyan Zhang, Evan C. Wegener, Nohor River Samad, James W. Harris, Kinga A. Unocic, Lawrence F. Allard, Stephen Purdy, Shiba Adhikari, Michael J. Cordon, Jeffrey T. Miller, Theodore R. Krause, Sichao Cheng, Dongxia Liu, Meijun Li, Xiao Jiang, Zili Wu, and Zhenglong Li*. Isolated Metal Sites in Cu–Zn–Y/Beta for Direct and Selective Butene-Rich C3+ Olefin Formation from Ethanol. ACS Catal. 2021, 11, 15, 9885–9897.

Contacts

Researcher POC:

Andrew Sutton

suttonad@ornl.gov

865-341-1220

Commercialization Manager:

Jennifer Caldwell

caldwelljt@ornl.gov

(865) 574-4180