In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

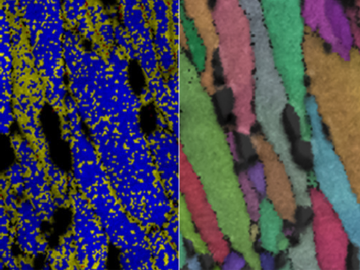

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Research into a new, unique technology to fabricate composite metal parts for a wide range of applications operating in extreme environments across the aviation, space and energy industries is showing promise for additive manufacturing.

Scientists at ORNL have invented a coating that could dramatically reduce friction in common load-bearing systems with moving parts, from vehicle drive trains to wind

Stan David, retired scientist and Corporate Fellow Emeritus at the Department of Energy’s Oak Ridge National Laboratory, was awarded the Joining and Welding Science Award from the Joining and Welding Research Institute at Osaka University, Japan.

Rigoberto Advincula, a renowned scientist at ORNL and professor of Chemical and Biomolecular Engineering at the University of Tennessee, has won the Netzsch North American Thermal Analysis Society Fellows Award for 2023.

Growing up in China, Yue Yuan stood beneath the world’s largest hydroelectric dam, built to harness the world’s third-longest river.

Nine engineers from ORNL visited 10 elementary and middle school classrooms in three school districts during National Engineers Week, Feb.

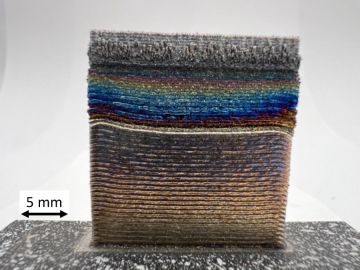

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

The U.S. Departments of Energy and Defense teamed up to create a series of weld filler materials that could dramatically improve high-strength steel repair in vehicles, bridges and pipelines.