Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Rigoberto Advincula, a renowned scientist at ORNL and professor of Chemical and Biomolecular Engineering at the University of Tennessee, has won the Netzsch North American Thermal Analysis Society Fellows Award for 2023.

Growing up in China, Yue Yuan stood beneath the world’s largest hydroelectric dam, built to harness the world’s third-longest river.

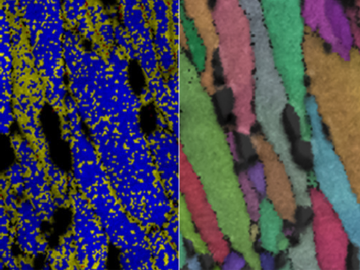

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

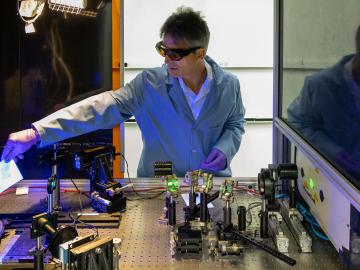

A multidisciplinary team of scientists at ORNL has applied a laser-interference structuring, or LIS, technique that makes significant strides toward eliminating the need for hazardous chemicals in corrosion protection for vehicles.

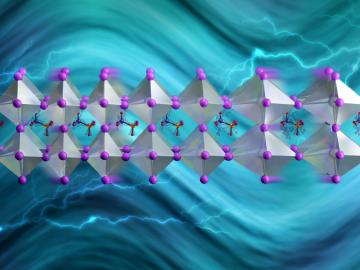

Led by ORNL and the University of Tennessee, Knoxville, a study of a solar-energy material with a bright future revealed a way to slow phonons, the waves that transport heat.

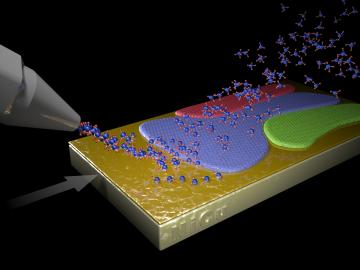

A new method to produce large, monolayer single-crystal-like graphene films more than a foot long relies on harnessing a “survival of the fittest” competition among crystals.