Electric vehicles can drive longer distances if their lithium-ion batteries deliver more energy in a lighter package.

Electric vehicles can drive longer distances if their lithium-ion batteries deliver more energy in a lighter package.

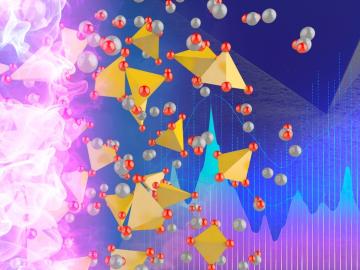

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

As current courses through a battery, its materials erode over time. Mechanical influences such as stress and strain affect this trajectory, although their impacts on battery efficacy and longevity are not fully understood.

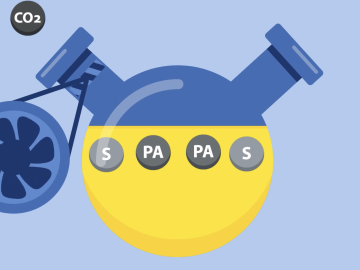

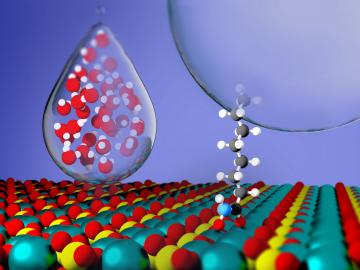

Using light instead of heat, researchers at ORNL have found a new way to release carbon dioxide, or CO2, from a solvent used in direct air capture, or DAC, to trap this greenhouse gas.

Since its inception in 2010, the program bolsters national scientific discovery by supporting early career researchers in fields pertaining to the Office of Science.

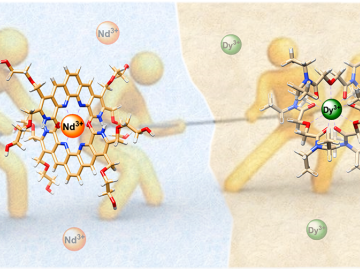

ORNL scientists combined two ligands, or metal-binding molecules, to target light and heavy lanthanides simultaneously for exceptionally efficient separation.

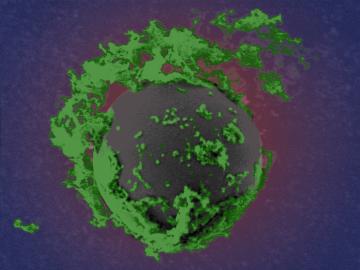

Critical Materials Institute researchers at Oak Ridge National Laboratory and Arizona State University studied the mineral monazite, an important source of rare-earth elements, to enhance methods of recovering critical materials for energy, defense

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

The Department of Energy’s Oak Ridge National Laboratory has exclusively licensed battery electrolyte technology to Safire Technology Group.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.