A collection of seven technologies for lithium recovery developed by scientists from ORNL has been licensed to Element3, a Texas-based company focused on extracting lithium from wastewater produced by oil and gas production.

A collection of seven technologies for lithium recovery developed by scientists from ORNL has been licensed to Element3, a Texas-based company focused on extracting lithium from wastewater produced by oil and gas production.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

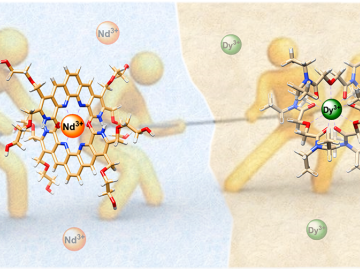

ORNL scientists combined two ligands, or metal-binding molecules, to target light and heavy lanthanides simultaneously for exceptionally efficient separation.

Nine engineers from ORNL visited 10 elementary and middle school classrooms in three school districts during National Engineers Week, Feb.

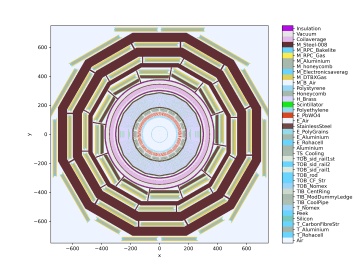

Scientists at the Department of Energy’s Oak Ridge National Laboratory are leading a new project to ensure that the fastest supercomputers can keep up with big data from high energy physics research.

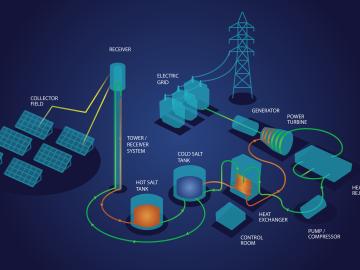

Oak Ridge National Laboratory scientists recently demonstrated a low-temperature, safe route to purifying molten chloride salts that minimizes their ability to corrode metals.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

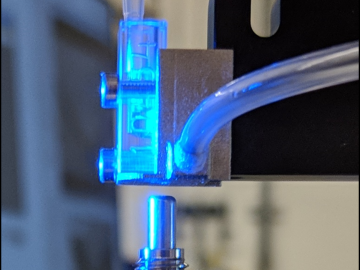

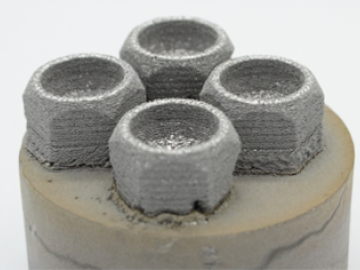

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufac

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity