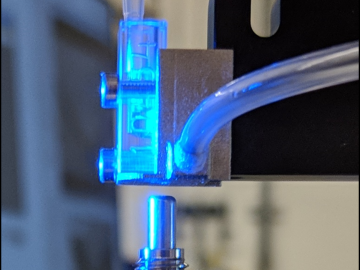

In response to a renewed international interest in molten salt reactors, researchers from the Department of Energy’s Oak Ridge National Laboratory have developed a novel technique to visualize molten salt intrusion in graphite.

In response to a renewed international interest in molten salt reactors, researchers from the Department of Energy’s Oak Ridge National Laboratory have developed a novel technique to visualize molten salt intrusion in graphite.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

In 2023, the National School on X-ray and Neutron Scattering, or NXS, marked its 25th year during its annual program, held August 6–18 at the Department of Energy’s Oak Ridge and Argonne National Laboratories.

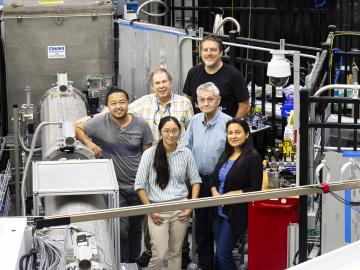

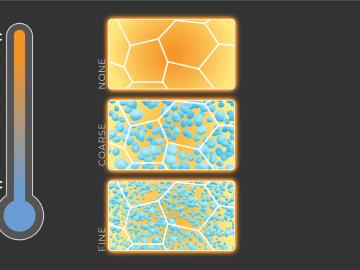

Scientists at ORNL and the University of Tennessee, Knoxville, have found a way to simultaneously increase the strength and ductility of an alloy by introducing tiny precipitates into its matrix and tuning their size and spacing.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

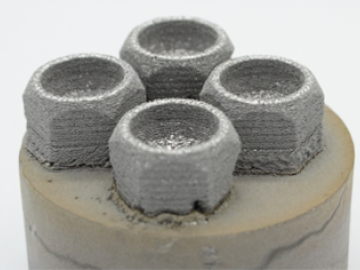

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufac

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity