ORNL will team up with six of eight companies that are advancing designs and research and development for fusion power plants with the mission to achieve a pilot-scale demonstration of fusion within a decade.

ORNL will team up with six of eight companies that are advancing designs and research and development for fusion power plants with the mission to achieve a pilot-scale demonstration of fusion within a decade.

ORNL has entered a strategic research partnership with the United Kingdom Atomic Energy Authority, or UKAEA, to investigate how different types of materials behave under the influence of high-energy neutron sources.

Three researchers at ORNL have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

ORNL's Larry Baylor and Andrew Lupini have been elected fellows of the American Physical Society.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

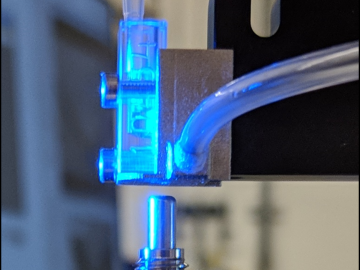

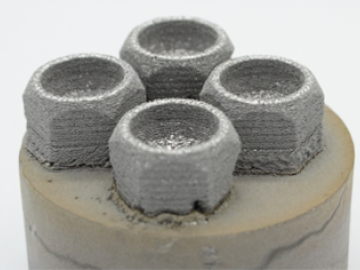

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufac

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.

A tiny vial of gray powder produced at the Department of Energy’s Oak Ridge National Laboratory is the backbone of a new experiment to study the intense magnetic fields created in nuclear collisions.

Oak Ridge National Laboratory has successfully developed and tested a novel sand casting technique to quickly design complex patterns to fabricate components for industry partner Emrgy Hydro, makers of hydropower devices designed to generate electricity