ORNL researchers Valentino Cooper, Howard Wilson and Jiaqiang Yan have been named Fellows of the American Physical Society, a distinction recognizing their outstanding contributions to their fields.

ORNL researchers Valentino Cooper, Howard Wilson and Jiaqiang Yan have been named Fellows of the American Physical Society, a distinction recognizing their outstanding contributions to their fields.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

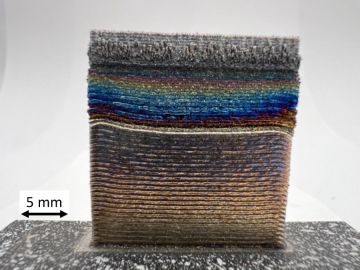

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Research into a new, unique technology to fabricate composite metal parts for a wide range of applications operating in extreme environments across the aviation, space and energy industries is showing promise for additive manufacturing.

Scientists at ORNL have invented a coating that could dramatically reduce friction in common load-bearing systems with moving parts, from vehicle drive trains to wind

Stan David, retired scientist and Corporate Fellow Emeritus at the Department of Energy’s Oak Ridge National Laboratory, was awarded the Joining and Welding Science Award from the Joining and Welding Research Institute at Osaka University, Japan.

For as long as he could remember, Brenden Ortiz wanted to do only one thing. “My childhood dream was to be a scientist. All I wanted to do was tinker in a lab like a pure scientist,” Ortiz said.

Nine engineers from ORNL visited 10 elementary and middle school classrooms in three school districts during National Engineers Week, Feb.

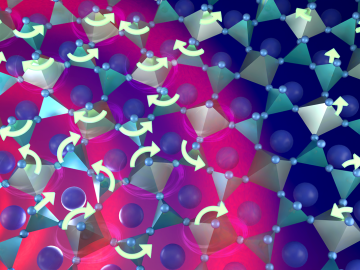

Warming a crystal of the mineral fresnoite, ORNL scientists discovered that excitations called phasons carried heat three times farther and faster than phonons, the excitations that usually carry heat through a material.

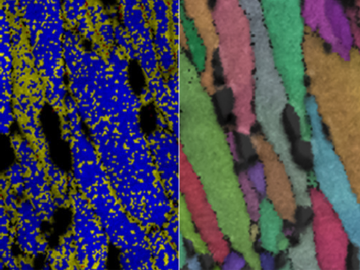

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.