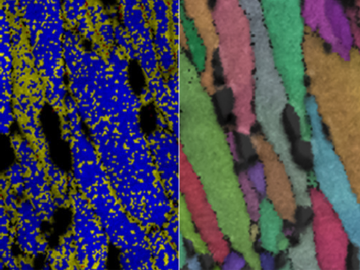

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

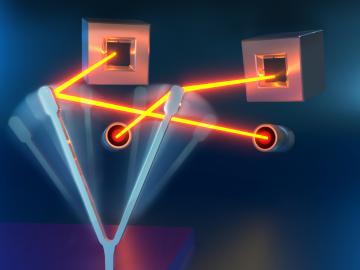

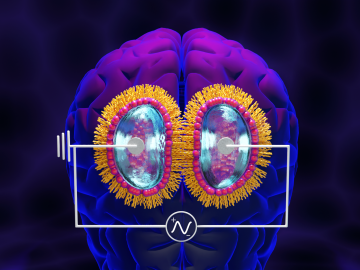

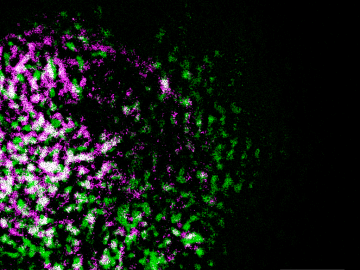

While studying how bio-inspired materials might inform the design of next-generation computers, scientists at ORNL achieved a first-of-its-kind result that could have big implications for both edge computing and human health.

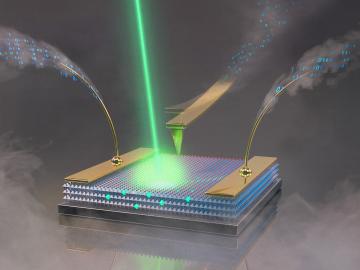

Researchers at Oak Ridge National Laboratory and Korea’s Sungkyunkwan University are using advanced microscopy to nanoengineer promising materials for computing and electronics in a beyond-Moore era.

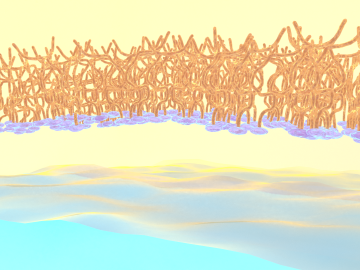

A multidisciplinary team of scientists at ORNL has applied a laser-interference structuring, or LIS, technique that makes significant strides toward eliminating the need for hazardous chemicals in corrosion protection for vehicles.

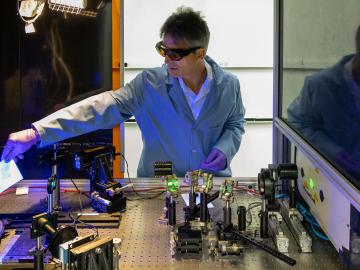

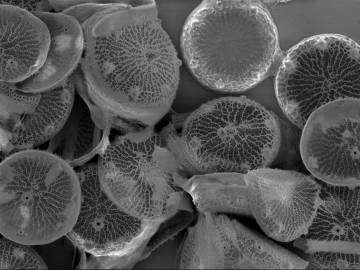

Oak Ridge National Laboratory researchers have built a novel microscope that provides a “chemical lens” for viewing biological systems including cell membranes and biofilms.

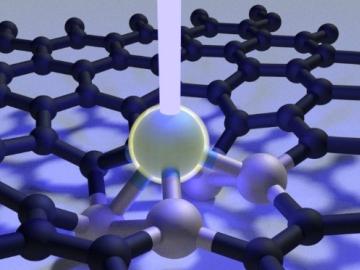

Scientists at Oak Ridge National Laboratory used a focused beam of electrons to stitch platinum-silicon molecules into graphene, marking the first deliberate insertion of artificial molecules into a graphene host matrix.

Students often participate in internships and receive formal training in their chosen career fields during college, but some pursue professional development opportunities even earlier.