Getting ORNL tech into the real world

Do you ever wonder how discoveries made at America’s national laboratories help American business? We asked ORNL Director of Technology Transfer Mike Paulus to shed a little light on the subject and to share the lab’s top 10 technology transfer success stories.

The best partner possible

ORNL scientists clearly invent technologies and processes, and the laboratory wants to make them available to U.S. companies with the goal of improving the national economy.

“A lot of our research output is put into the public domain in scientific publications,” ORNL Director of Technology Transfer Mike Paulus said, “but there are times when companies have to make large investments to turn our scientific results into products or services, so they need some exclusivity in order to get a return on their investment.”

To make these matches, Paulus’ team has to align the needs of both researchers and businesses.

“Our first job is to help researchers identify inventions that could have commercial potential and work with them to patent these inventions,” Paulus said. “Our second job is to engage with businesses, connect them with the researchers, provide them with the intellectual property they need to succeed, and then, often, to continue to take advantage of the laboratory’s capabilities.”

Tech transfer successes

When these pairings succeed, ORNL technologies are licensed, refined and brought to market by companies in the private sector. Royalty fees are managed by ORNL contractor UT-Battelle with oversight from DOE.

What follows are the laboratory’s top 10 technology transfer successes based on licensing revenue.

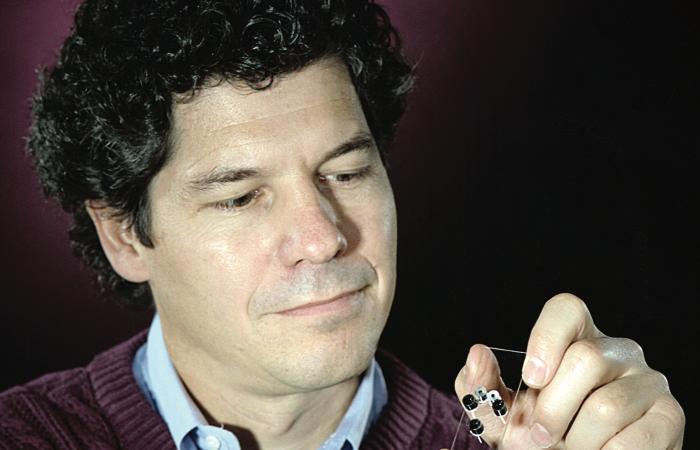

Lab on a chip — In 1987, ORNL chemists Mike Ramsey and Stephen Jacobson devised a way to speed up chemical separations processes by passing small samples through what amounted to a tiny chemistry lab etched into a glass microscope slide.

“They came up with a really innovative way to do high-throughput, flexible chemistry,” Paulus said. “Their invention got out in front of a market that was growing rapidly.”

Ramsey and Jacobson patented the device in 1995, and Ramsey co-founded a company, Caliper Technology Corporation, to further develop the technology. The “lab on a chip” concept has evolved to encompass genetics research, pharmaceutical development and other biochemical separations processes.

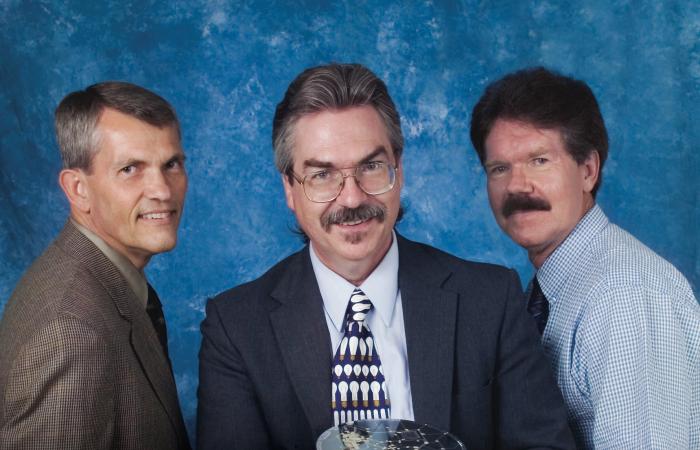

Wireless temperature sensors — In 1994, while ORNL scientists Bob Lauf and Don Bible were attending a meeting at Sematech, they learned of an industry problem: Wires from the sensors used to ensure uniform heating of semiconductor chips were getting in the way and affecting the reliability of measurements.

“As I understand it,” Paulus said, “Lauf and Bible went to a bar, pulled out a napkin, sketched an idea, came home, and — with the help of ORNL engineer Carl Sohns — built a prototype and filed a patent. Then they went back to the [Sematech] representative and said, ‘We have a solution: a wireless temperature sensor.’”

ORNL licensed the patent to SensArray in 2001, and in 2005 the SensArray Integrated Wafer won Semiconductor International and R&D 100 awards.

Silicon carbide whisker-reinforced ceramic composites for cutting tools — In the early 1980s, ORNL’s George Wei, Terry Tiegs and Paul Becher created a ceramic composite reinforced with silicon carbide whiskers — like rebar in concrete — making it ideal for cutting tools and other wear-resistant applications. The technology was licensed in 1986 to Advanced Composite Materials Corp. and was later distributed by Greenleaf Tooling Solutions.

“The material was really successful in tooling applications,” Paulus said. “Those guys are still selling products based on this material, and the technology is still making a difference long after the patents expired.”

Handheld mass spectrometry system — Ramsey, the same researcher who co-developed “lab on a chip,” worked with ORNL’s Bill Whitten to develop a handheld mass spectrometer, which is used to identify the composition of samples in fields like materials science, forensics, pharmaceuticals, biology and chemistry. The technology was licensed to 908 Devices in 2012. ORNL received equity in the company as a part of the licensing fee, so when its $150 million initial public offering closed in December 2020, ORNL was able to sell its stock.

“That was the first stock sale that we’ve had since I’ve been here,” Paulus said. “That was an exciting day for the lab.”

RABiTS (Rolling-Assisted Biaxial Textured Substrate) — In 1996, ORNL scientists Amit Goyal and Parans Paranthaman led the development of new methods and materials for producing high-temperature superconducting materials. The work was supported by a cooperative research and development agreement, or CRADA, with American Semiconductor, and one of the technologies was licensed to the company in 2000. A second technology was licensed to SuperPower Inc. in 2007.

“This is an example of a sustained, focused program funded by DOE to advance a technology that resulted in a huge patent portfolio and companies,” Paulus said.

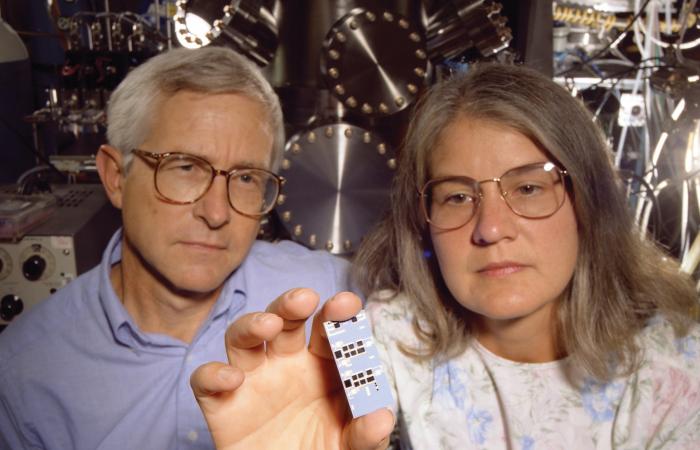

Thin-film, solid-state battery technology — “Nancy Dudney, John Bates and Bernd Neudecker developed a solid-state electrolyte technology in the 1990s that enabled very small batteries to be printed on circuit boards using semiconductor technology,” Paulus said.

The technology was developed through a handful of CRADAs and was eventually licensed to several companies, each of which marketed solid-state lithium-ion microbatteries. These thin-film batteries are longer lasting, more robust and safer than the current generation of liquid electrolyte–based lithium-ion batteries.

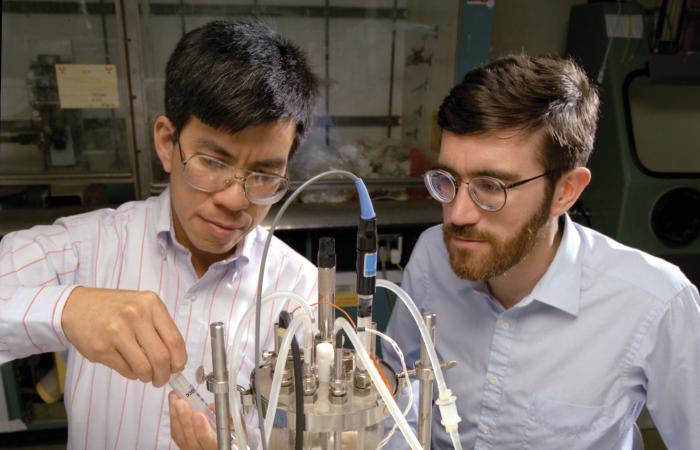

Bio-succinic acid process — The aim of this project was to find a way to produce succinic acid — a building block for numerous chemical products — that did not rely on petroleum-based chemicals. ORNL scientists Nhuan Nghiem and Brian Davison collaborated with colleagues at Argonne National Laboratory and the National Renewable Energy Laboratory to do just that, devising a microbial process for creating succinic from biomass. A patent for the technology was filed in 1997, and the technology was later licensed by Applied CarboChemicals, which, after a merger, became JV BioAmber. The company built a demonstration plant in France in 2010 and operated it for several years.

LandScan — The LandScan database combines a range of data, including census information and satellite imagery, to produce very-high-resolution, graphical representations of global population distribution. It was developed in 1998 by ORNL scientists Budhu Bhaduri, Phillip Coleman, Edward Bright, Amy Rose and Marie Urban.

Some of LandScan’s biggest impacts have been seen during times of natural disaster, when relief agencies ask researchers to use the database to predict where people impacted by events such as earthquakes, tornadoes and tsunamis will go when they evacuate. This capability enables agencies to deliver relief supplies and other resources to the right places.

LandScan was licensed to East View Geospatial from 2012 to 2021. It has been distributed through an open-source license for academic use since 2021.

Content-based image retrieval system for improving semiconductor yield — “I see ORNL’s Automated Image Retrieval Technology — AIR — as a precursor to artificial intelligence–based image analysis,” Paulus said. “It was developed by ORNL scientists Ken Tobin, Regina Ferrell, Tom Karnowski, Shaun Gleason and Hamed Sari-Sarraf.”

The researchers compiled a database of known defects in semiconductor processing, then built a tool, AIR, to enable users to quickly compare images of problematic semiconductor wafers with those in the database. Based on that comparison, they can determine what went wrong in the manufacturing process. AIR was licensed in 2004 to August Technology Corporation and was marketed under the trade name TrueADC.

Open port sampling interfaces for mass spectrometry — ORNL chemists Gary van Berkel and Vilmos Kertesz have specialized in developing innovative interfaces between mass spectrometry systems and samples. In this case, their innovation enables even novice users to load solid or liquid samples into a mass spectrometer and achieve reliable results.

“This is an overnight success that took more than 20 years,” Paulus observed wryly. “ORNL has partnered with SCIEX since 1996. In that time, we’ve had multiple cooperative R&D agreements. In 2022, SCIEX launched a new flagship mass spectrometry system, and our technology is an integral part of that system.”

Always opportunities to do things better

Each of these technology transfers was enabled by the Bayh-Dole Act of 1980, the law that allows universities, national laboratories and small businesses to patent and profit from discoveries made through federally funded research.

“It has been said that the Bayh-Dole Act is possibly the most inspired piece of legislation to be enacted in the U.S. over the past half century,” Paulus said.

“The incentive it provides has made a big difference in moving R&D from federal laboratories to business and industry in the U.S. Empowering institutions that invent to connect with companies that produce ensures that there’s a direct path into the marketplace.”