CNMS users and scientists use the Nanoscribe Photonics Professional GT stereolithography system to create intricate 3D micro- and nano-scale structures using principles of additive manufacturing. This tool is uniquely suitable to add 3D structures to on-chip structures already processed using conventional lithographic patterning techniques. Alternatively, this tool enables microscale 3D printing on virtually any flat or arbitrary shaped substrates and allows researchers to create untethered 3D structures.

Nanoscribe Photonics Professional GT system combines principles of direct laser writing (DLW) and 2-photon polymerization to achieve 3D printing with resolution and fidelity well above those provided by any other commercially available 3D printers. The tool integrates an inverted optical microscope, femtosecond laser, high speed galvo mirror laser scanner and a high precision piezo-stage in a user-friendly computer controlled system that accepts input designs in the industry-standard STL file format. The intuitive interface, optical autofocusing and availability of various sample holders provides a straightforward workflow from the design to implementation of arbitrary complex structures as required by the project goals.

Applications

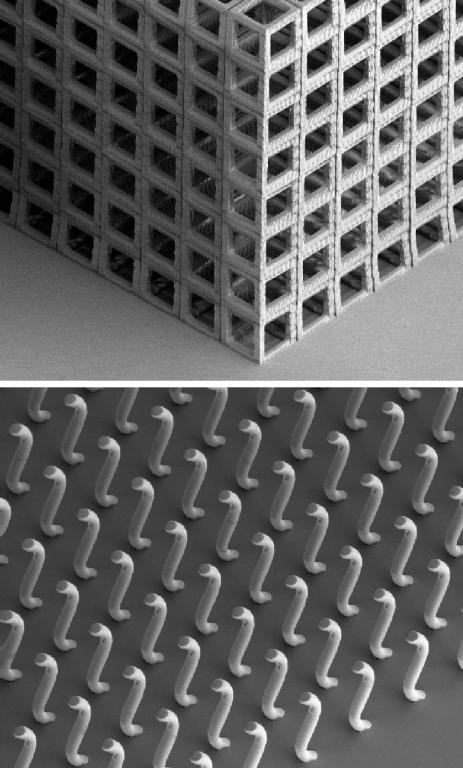

Micro/nano-scale scale 3D printing is a rapidly evolving enabling technology with applications in many cross-disciplinary areas, such as biomimetic sensing, biomedical devices, soft robotics, active colloids, mechanical metamaterials, nanophotonics and fundamental nanoscience. Examples of recent CNMS user projects that relied on the Nanoscribe tool include 3D printing of asymmetric textures with unusual wetting properties, bioinspired antennas for chemical sensing, porous scintillator media, and carbon electrodes for implantable electrochemical sensors.

Specifications

- Light source: Femtosecond fiber laser (780 nm, up to 40 mW average power, 100 fs pulse duration, 80 MHz repetition)

- Lateral resolution: 160-200 nm (with 63x writing objective)

- Vertical resolution: 500-600 nm (with 63x writing objective)

- Single writing field: up to 300 x 300 x 300 mm3

- Laser scanner beam velocity on the sample surface: up to 50 mm/sec

- Typical printing areas: up to 100 mm2

- Typical printing volumes: up to 1 mm3

- Applicable photoresists: SU8, vendor supplied diacrylate based liquid photopolymers (IP-S, IP-DIP)

- Material of the resulting structures: Cross-linked polymers

- stable up to 100 °C,

- undergoes 20-40% shrinkage between 100-250 °C,

- partially oxidizes at 250-400 °C

- carbonizes above 400 °C

Recent Highlights

Moth-Inspired Antenna