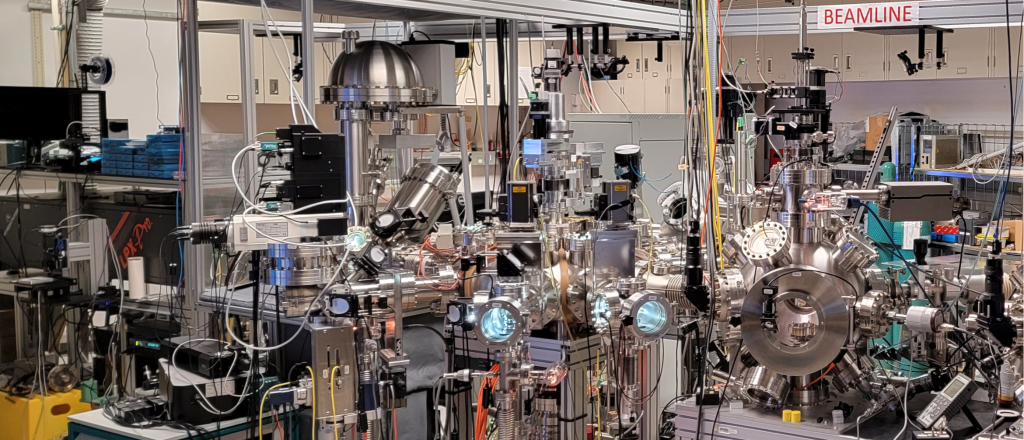

Highly automated pulsed laser deposition (one conventional and one codeposition chamber) and robotic sample transfer are combined with in situ diagnostics (RHEED and Ion Probe) and post-growth analysis (XPS and Raman/PL) to implement a machine learning based workflow for materials synthesis, discovery, and algorithm development.

Features

- Laser source: 248 nm excimer laser, 1 J/pulse, 1 Hz to 20 Hz repetition rate

- Number of targets: four in each chamber with computer-controlled target sequencing

- Spot size at target: adjustable from sub millimeter to a few millimeters

- Fluence at target: adjustable from sub 1 J/cm2 up to 3 J/cm2

- Deposition rate: adjustable from sub angstroms to almost 1 angstrom per laser shot

- In situ diagnostics: high pressure RHEED and Ion Probe

- Base pressure: 2x10-7 torr

- Ambient: currently argon or oxygen, pressured controlled to multiple millitorrs up to 100s of millitorrs

- Heating: Laser up to 1000°C

- Substrate size: 5 mm x 5 mm

- 16 sample garage

- Target-to-substrate: fixed at 50 mm

- Witec RISE for post-growth optical characterization

- Scienta Omicron XRS Lab for post-growth compositional analysis

- Python-powered workflow