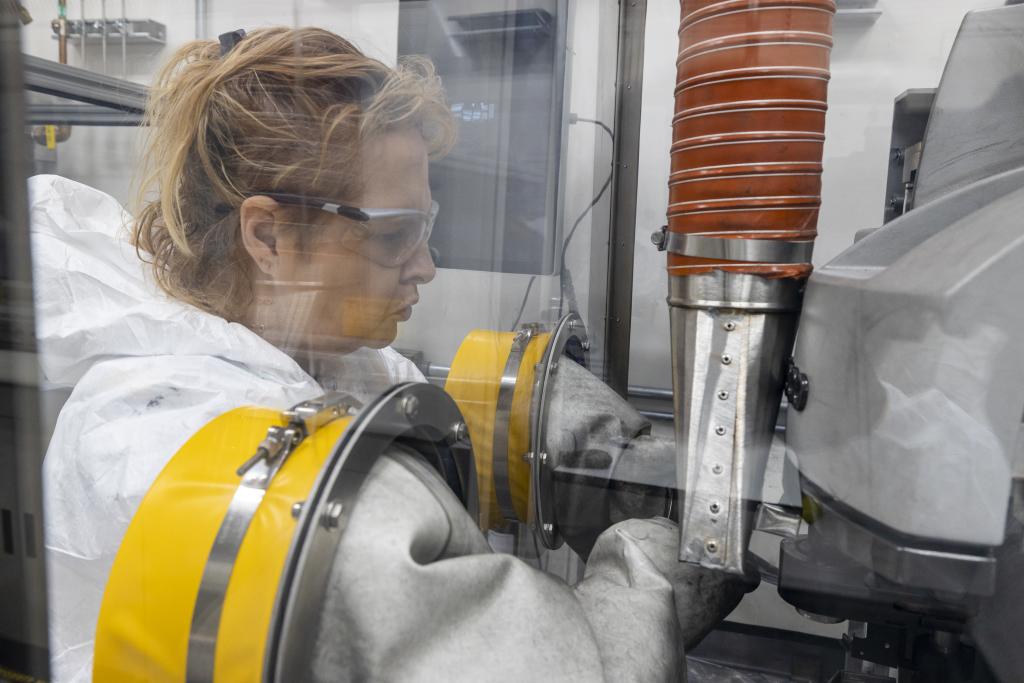

The Low Activation Materials Development and Analysis (LAMDA) laboratory is an ORNL facility dedicated to ensuring the safety and economics of current- and future-generation nuclear power systems.

Typically, radioactive specimens are handled in hot cell environments that are limited in space and allowable equipment, making it difficult or impossible to perform many experiments. LAMDA enables the study of “low activation” materials, or samples with low radiological activity (up to 100 mrem/hr), outside of a hot cell and with a full suite of tools that provide vital materials properties and structural data to help us understand the behavior of materials in nuclear environments. Samples tested in LAMDA come from a range of sources, including accelerated irradiation experiments from materials test reactors, such as the High Flux Isotope Reactor (HFIR), recovered materials from decommissioned commercial reactors, surveillance specimens from operating reactors, and even components used to produce neutrons at the Spallation Neutron Source.

When materials—whether metals, ceramics, graphite, concrete, nuclear fuels, electronic sensors, or anything else in the nuclear industry—are exposed to radiation in service, their properties evolve. Examining those materials, such as concrete or pressure-vessel steel from retired commercial reactors, can help us understand and prolong the longevity of the nation’s nuclear fleet. Accelerated testing at HFIR and examination post-irradiation in LAMDA inform the design of high-performance materials for future reactors. In-house resources and expertise enable researchers to safely investigate the impacts of radiation-induced changes to materials properties, ranging from changes in strength and toughness to thermal conductivity and the coefficient of thermal expansion. Radiation modifies the original properties of reactor materials over time. For example, neutron irradiation produced in a commercial reactor can make the pressure vessel materials brittle. Radiation can also degrade insulators making them more conductive to electricity, which can cause issues in plant electronics.

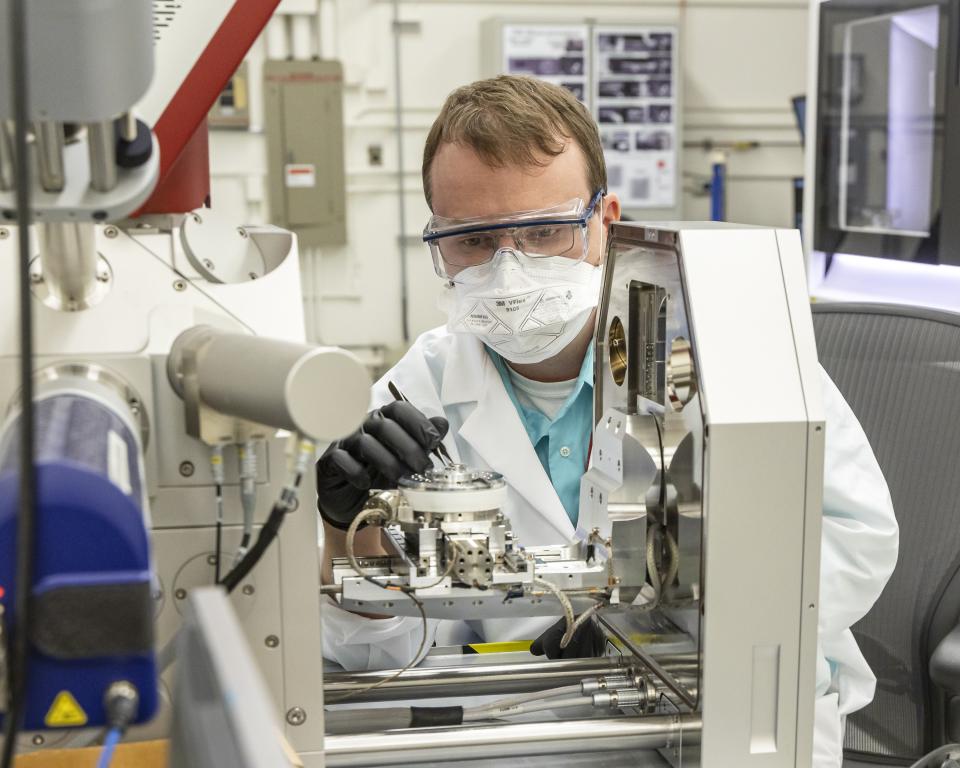

In addition to radiation, reactor components experience high temperatures and need to operate continually under extreme heat loads. LAMDA’s analytical suite enables these stresses to be quantified from the macroscopic scale all the way down to the atomic scale – 9 orders of magnitude. Micro- and macroscale measurements provide insights on bulk, mechanical, electrical, and thermophysical properties that change as materials perform in extreme environments. Advanced microscopy and microanalysis shed light on the link between atomic structure and material properties as these evolve from the as-manufactured to end-of-life state. Understanding how materials change in reactor environments, from macro- to atomic scales, allows us to better predict performance lifetimes and design future robust reactors. LAMDA provides the science that enables the future of clean, safe nuclear energy and plays a central role in ORNL’s research and development of new materials for extreme conditions, especially high-temperature alloys for nuclear energy, industrial, and automotive applications.