2012

MDF Advanced Manufacturing Shapes the future

The catalyst begins with 26 ORNL-industry MOUs with materials suppliers, equipment suppliers, and end users of additive and carbon fiber technologies. MDF will leverage ORNL’s unmatched capabilities in materials, neutrons, and computational science to develop innovative manufacturing technologies, helping large and small companies alike.

2012

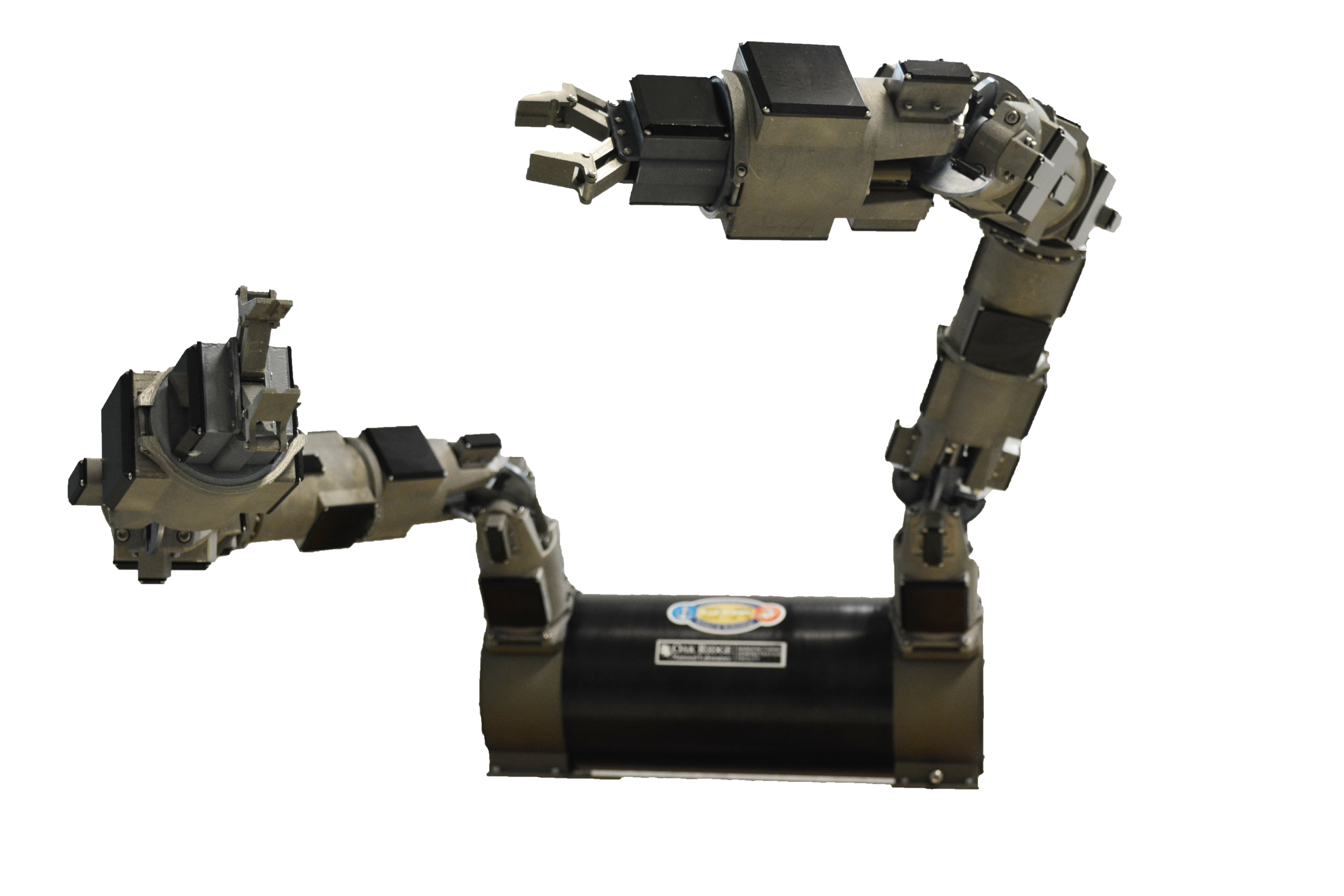

The Art of the Complex One Layer at a Time

Electron-beam AM produced a fully functional titanium powder robotic hand holding a mesh ball, which costs approximately 10 times less than similar devices while commanding 10 times more power than other electric systems. It is composed of only 46 parts and can be manufactured and assembled within 40 hours.

2012

Under Water Workers

ORNL demonstrates a set of 3D-printed robotic arms for underwater use by the US Navy using an alloy of titanium, aluminum, and vanadium. The arms have seven degrees of freedom and show proof of design in additive manufacturing.

December 2013

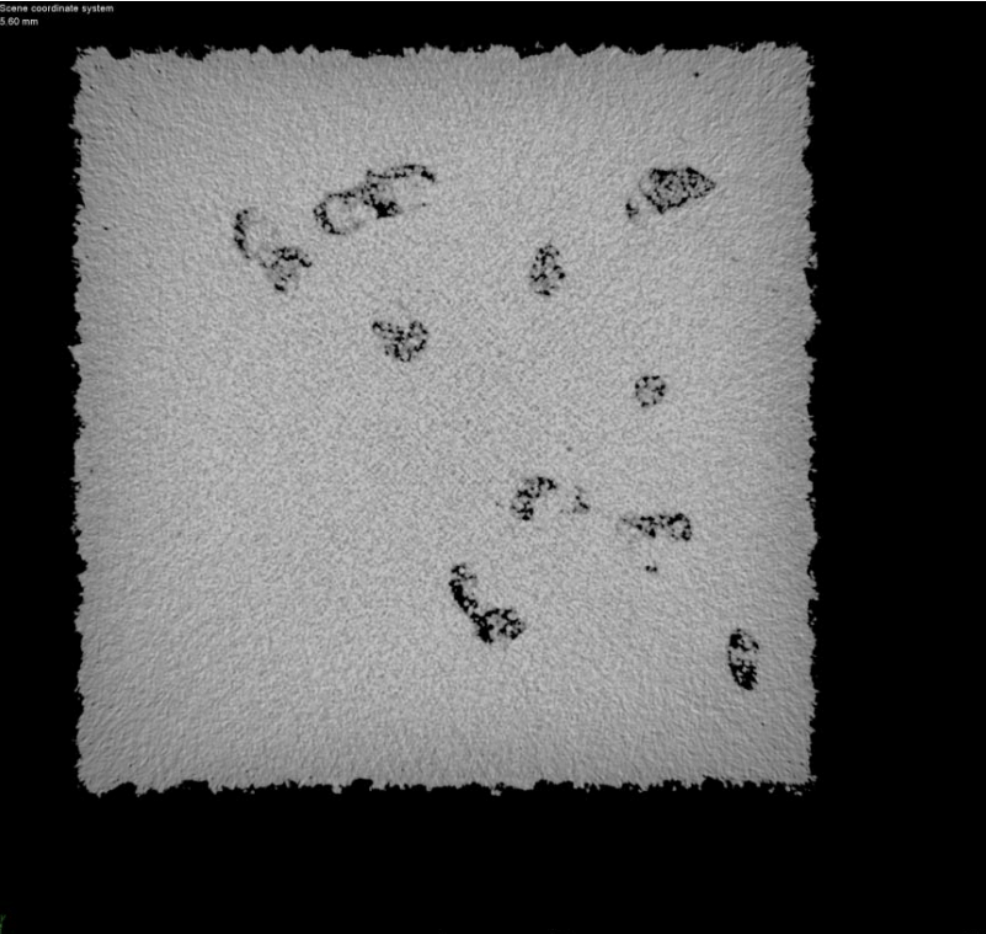

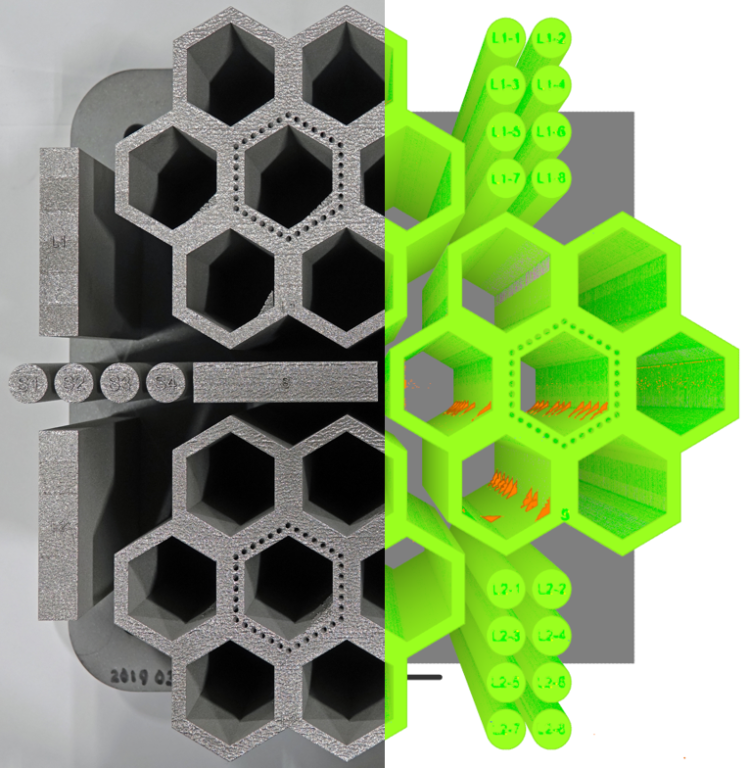

Detecting Defects with AI

ORNL demonstrates an innovative in-situ quality control system for electron beam melting (EBM) technology, presenting a promising alternative to traditional non-destructive techniques like X-ray computed tomography. This new technology combines an infrared camera with artificial intelligence to offer near-real-time 3D mapping of porous defects within additively manufactured components.

2014

Driving the Impossible

MDF researchers fabricate the world’s first 3D-printed electric car with Cincinnati Inc. and Local Motors live at IMTS in front of more than 100,000 people. The drivable vehicle is printed with a thermoplastic composite in just 44 hours, then milled and assembled over three days.

November 2014

Sophisticated Shelby Cobra 3D Printed Car

MDF researchers take a Shelby Cobra from concept to drivable car in six weeks, debuting it at the 2015 Detroit Auto Show. Parts are printed in 24 hours, then machined, sanded, and polished, resulting in a 1,400-pound total weight—500 pounds of 3D-printed parts and 20 percent carbon fiber material.

March 2015

All Hail Hydro Power

MDF enables Emrgy, an Atlanta based startup, to manufacture low-head modular hydropower devices for shallow water streams with untapped energy potential. In 2017, Emrgy installs the devices for demonstration in Denver, Colorado. In 2019, Emrgy signs an agreement with GE Renewable Energy for global commercialization of Emrgy’s hydropower units.

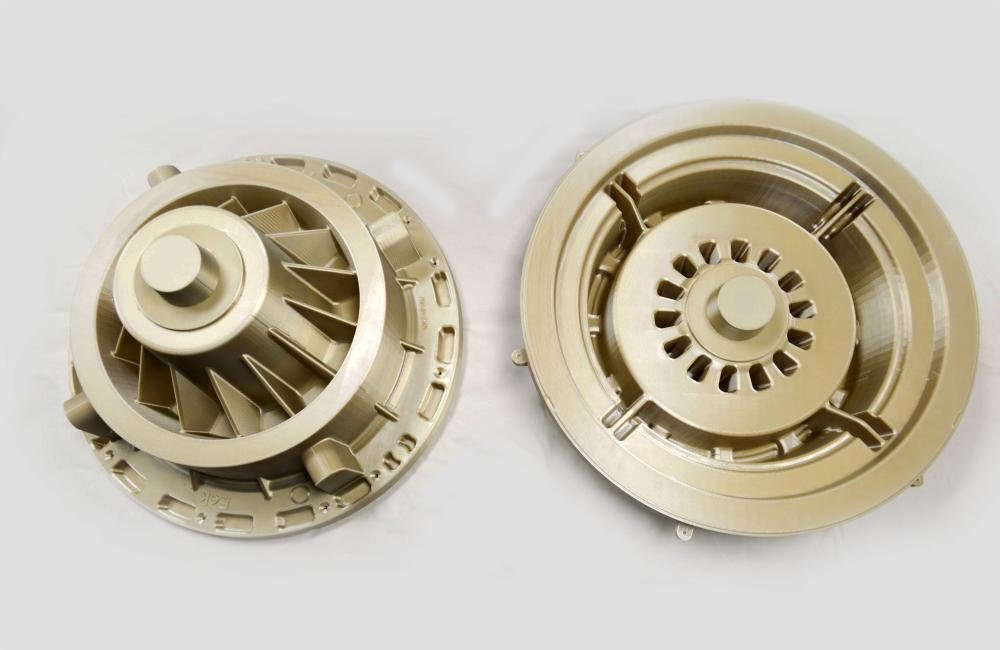

2015

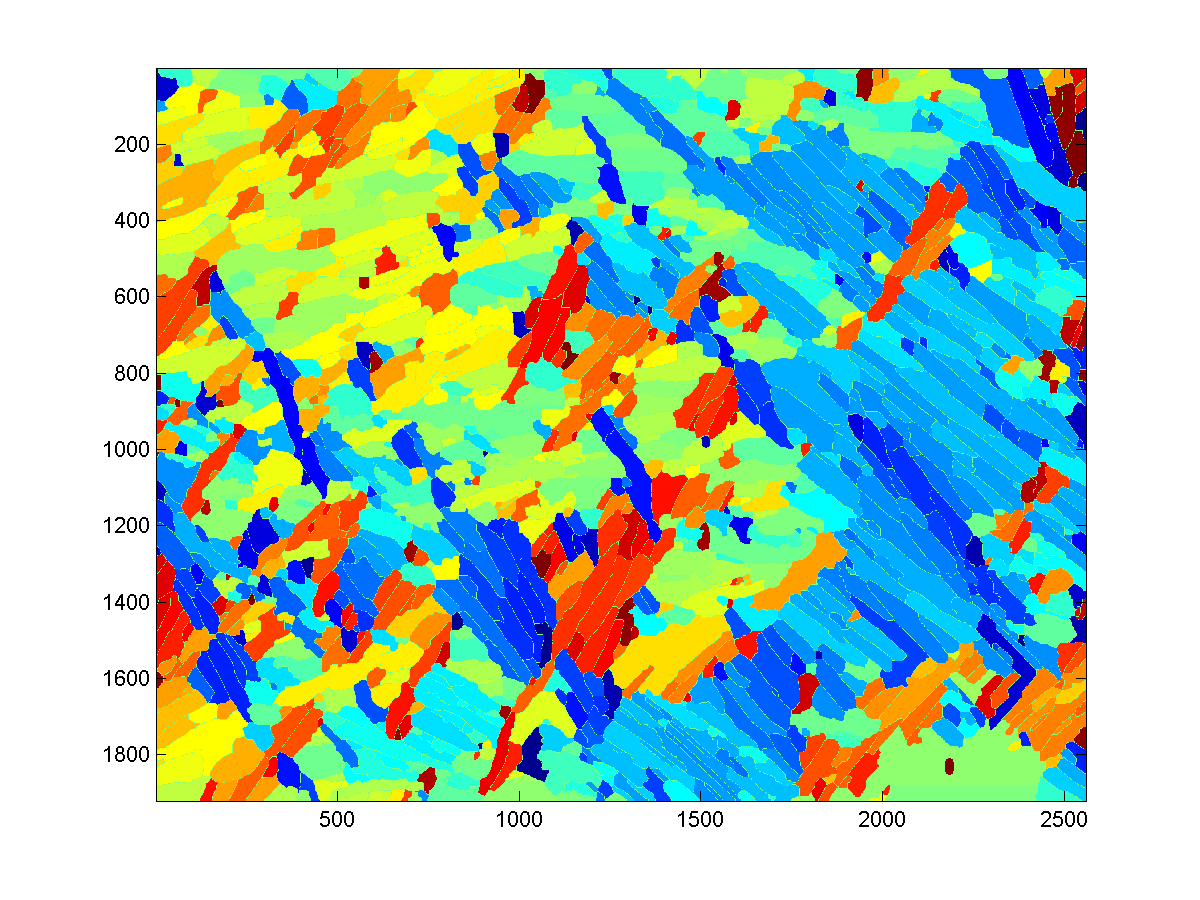

Additive Manufacturing Technologies Enable New Grain Control Capabilities

Researchers at MDF demonstrate new achievement within metals AM technologies by building metal components with site specific control on crystallographic orientation of grains using the electron beam melting process.

2015

Energy Integration for Car and Home

ORNL demonstrates a new approach to energy use, storage, and consumption through large-scale 3D printers. The Additive Manufacturing Integrated Energy demonstration, or AMIE, is a combination house and vehicle showcasing additive mamonufacturing’s rapid prototyping potential in architecture and design.

Watch the video- https://www.youtube.com/watch?v=RCkQBlFJRN4

2016

Bamboozled in Miami

Using over 10,000lb of material, two bamboo pavilions are created for the DesignMiami expo. After the expo ends, they are used to house an outdoor cultural program for the next two years. The pavilions demonstrate the potential to 3D print materials from highly replenishable, often difficult to work with, material.

2016

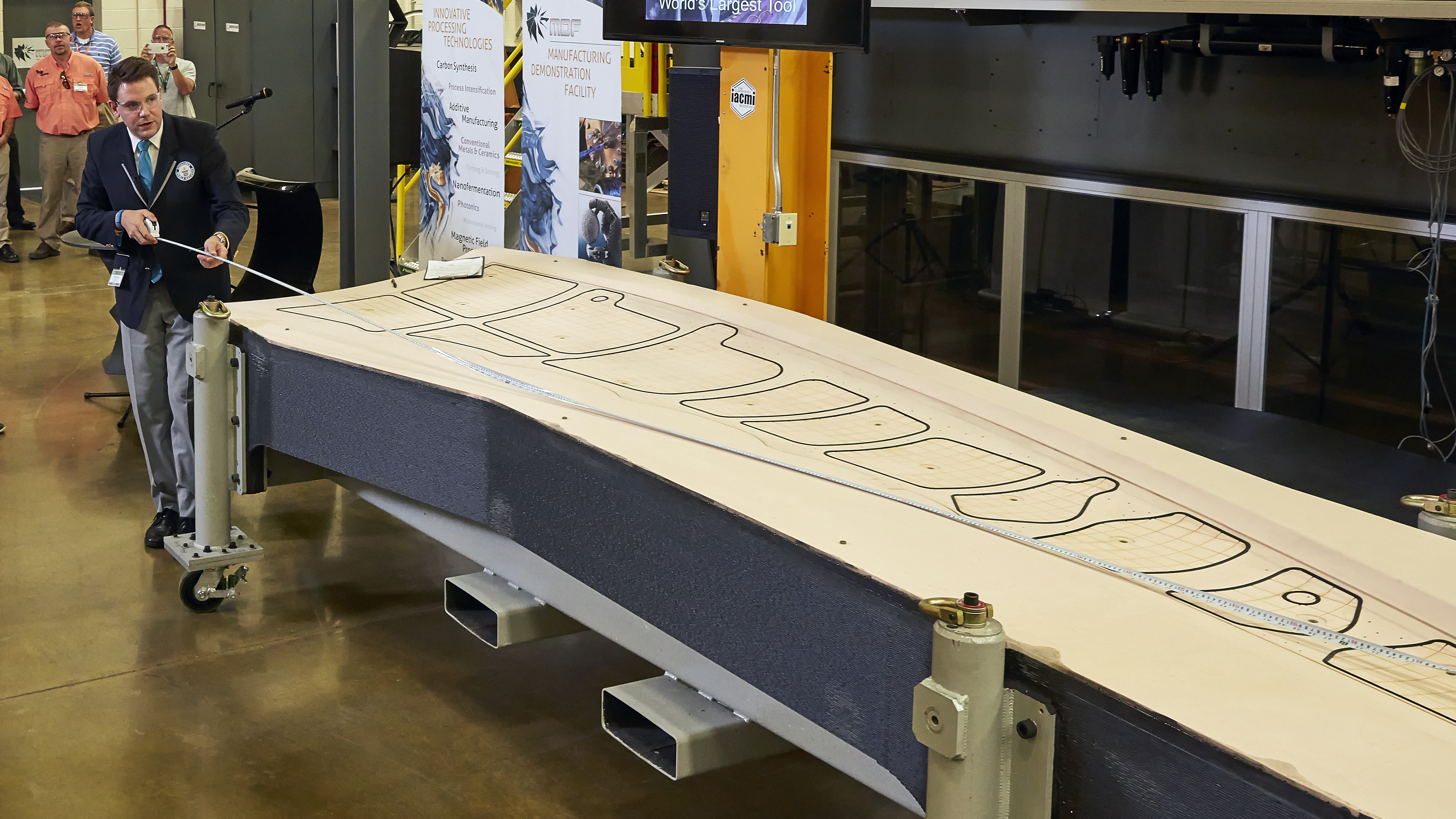

It’s a Guiness World Record!

A 3D-printed “c tool” developed for Boeing receives a Guiness World Record for the largest solid 3D-printed item. The tool measures 17.5ft long, 5.5ft wide, 1.5ft tall, and weighs about 1,650lb. The tool is used on the production floor, initiating widespread use of 3D printed tooling.

September 2016

3D Printing Digs Deep

The cab, hydraulically articulated arm (or stick), and heat exchanger for a fully functional excavator are additively manufactured. The prototype demonstrates a breakthrough in large-scale AM production, as well as the feasibility of printing with low-cost metal alloys.

2017

We All Live in a (Black Submersible Hull)

In only four weeks, a 30ft-long submersible hull demonstrator is created for the US Navy using Big-Area Additive Manufacturing (BAAM). BAAM technology reduced production costs in creating the hull by 90 percent and proves the potential to create on-demand vehicles while saving time and energy.

2018

Autonomous Bus

In conjunction with the Vehicle Systems Integration Laboratory, researchers create ORNL’s first autonomous bus, nicknamed GROVER, which is used to test sensors and controls, batteries, and power electronics in a single platform that can move in any direction.

September 2018

Producing a Die in a Day

Researchers design, print, machine, and use five dies in a single day for 130,000 attendees at the International Manufacturing Technology Show, the largest manufacturing conference in North America. Ordinarily, the creation of die casts could take anywhere from weeks to months.

March 2019

Concrete Sugar Cubes

Polymer extrusion is used to create carbon fiber reinforced thermoplastic molds for precast concrete façade segments of the Domino Sugar Refinery in Brooklyn, New York. Each mold can cheaply cast 200+ concrete parts, a 75% cost saving per mold over traditional wood molds.

July 2019

Big Things for Small Business

Through resources enabled by AMO and ORNL, Emrgy signs an agreement with GE Renewable Energy for global commercialization of Emrgy’s hydropower units. GE will offer Emrgy’s product in select markets worldwide, allowing Emrgy to compete on the same playing field as Fortune 500 companies

August 2020

Peregrine Launches

Peregrine, an AI software for laser powder bed 3D printers, supports the advanced manufacturing digital thread that collects and analyzes data through every step of the manufacturing process, from design to feedstock selection to the print build to material testing. Peregrine quickly becomes ORNL’s most licensed AI technology.

2020

Concrete Ideas

Researchers create a machine tool base using an additively manufactured polymer mold filled with fiber reinforced concrete. The base is shown to have a better stiffness-to-dampening ratio than traditional cast iron bases while being significantly cheaper and faster to produce.

2020

High Temperature Turbine Blades

Using powder bed additive manufacturing, and working with Siemens Technology, 3D-printed turbine blades are created from a highly non-weldable nickel superalloy (IN718) and certified for use in gas powered turbine engines. This demonstration paves the way for many more wire-arc advancements to follow.

2020

Building Walls and Breaking Barriers

A 3D-printed concrete smart wall showcases the possibility to function as a heating and cooling system for a room using an embedded thermal storage system, drastically reducing energy use. Field tests reveal that the technology could yield more than an 8 percent savings on energy.

2020

Healthcare supplies

In the fight against COVID-19, researchers at MDF pivot their manufacturing expertise to produce custom molds and tooling for the mass production of millions of N95 masks, as well as a variety of other healthcare supplies such as test kits and face shields.

2020

Face Mask Production Speed

Working alongside MDF in the fight against COVID-19, the Carbon Fiber Technology Facility applies melt-blowing capability to the production of ORNL-developed self-sanitizing filter material for N95 masks. The technology enables the production of more than one million face masks and respirators per day and creates 1,500 jobs.

March 2021

Quick Cooling Tooling

In collaboration with DTS, researchers at MDF use a wire-arc technology system to 3D print a hot stamping die for an automotive “b-pillar.” The die takes less than half the time to produce than those made using traditional methods and performs better in the extreme heat faced during large-scale production.

October 2021

3D Printing Goes to Space

Researchers manufacture a graphite nose cone reinforced with carbon fiber for a US Navy space rocket. The rocket launch demonstrates the potential for 3D-printed materials to resist the extreme temperatures and harsh environments faced in spaceflight.

2021

3D Printing Goes Nuclear (Power)

Four fuel assembly brackets are additively produced and rigorously analyzed using AI-based software, then installed in TVA’s Browns Ferry Nuclear Plant in Athens, Alabama. The installation demonstrates the potential for 3D-printed parts to be rapidly certified and qualified for use in highly regulated environments.

2021

3D Printing Can Take the Heat

A 3D printed thermal protection shield (TPS) is installed onboard NASA’s Cygnus spacecraft for a supply mission to the International Space Station, marking the first time an AM heat shield has been sent to space. The TPS not only protected Cygnus on the way up, but successfully allowed reentry.

2022

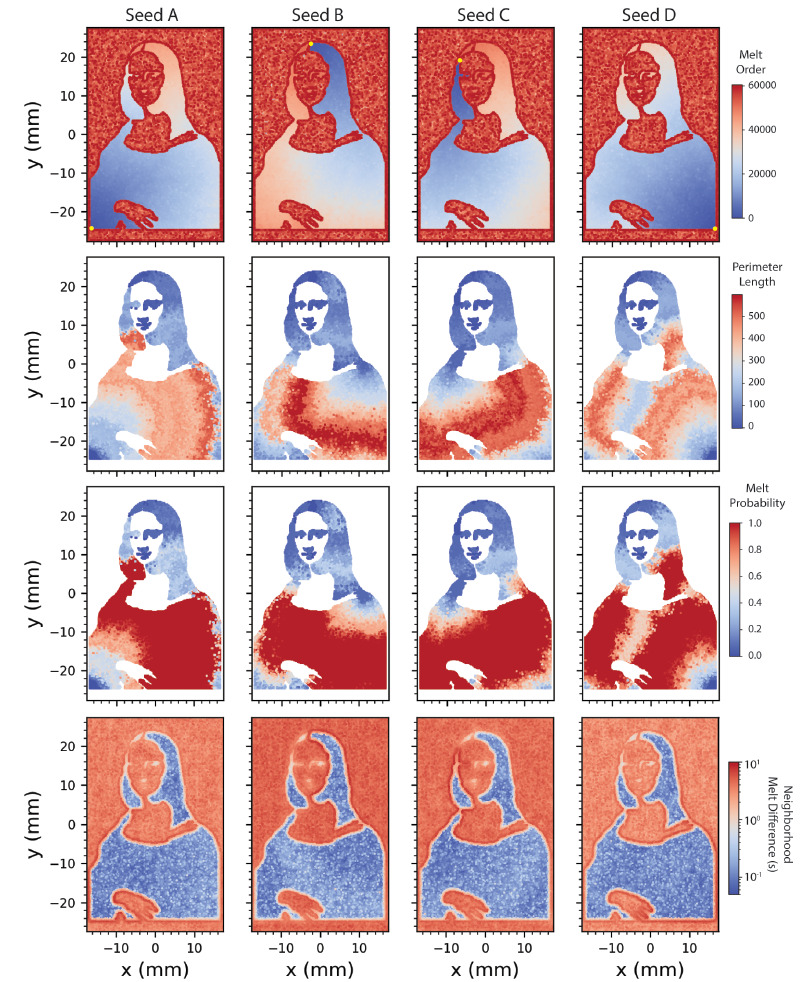

Reinventing the Mona Lisa

Using the texture manipulation techniques discovered in 2014, researchers use EBM to create a copy of the Mona Lisa in a piece of nickel chromium alloy no larger than a sticky note. The work of art demonstrates the extreme precision capability of modern 3D-printing techniques to achieve microstructure control.

2022

Speedcast

ORNL and MSC collaborate to improve CNC milling performance by creating a digital twin of a CNC machining center that predicts the optimum stable speeds, feeds, and depth of cut in automated machining. Initial results reveal massive improvements in profits and efficiency.

2022

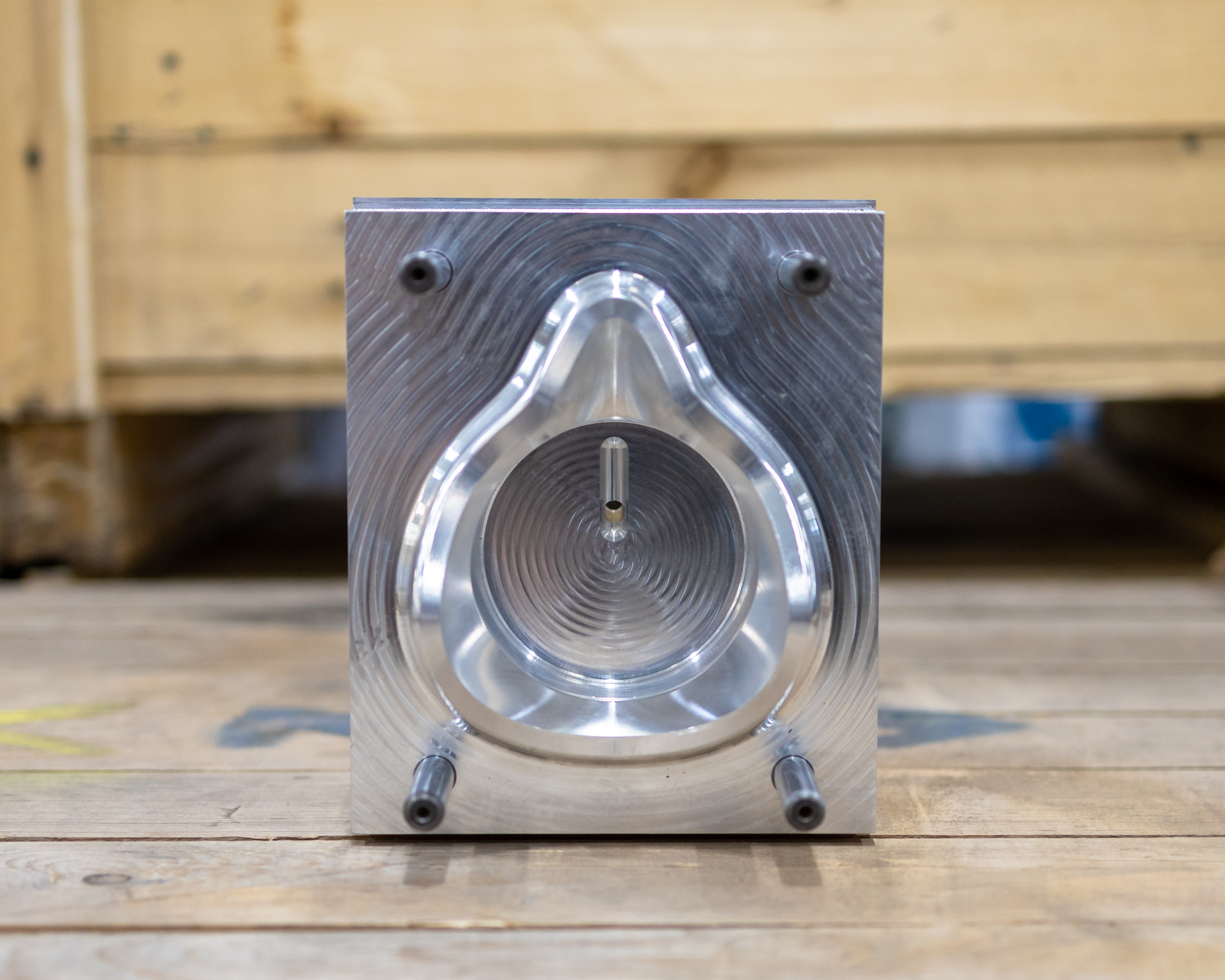

3D Printing Can Handle the Pressure

In just 19 hours, researchers 3D print a high-pressure die casting mold for a marine engine component using 410 stainless steel parts. The technology improves the productivity of pre-existing US tooling and demonstrates 3D printing’s ability to craft molds that can handle high pressure for extended periods.

September 2023

Clean Racing

In collaboration with Airtech Advanced Materials Group, researchers use recycled materials to 3D print a new splitter mold and help the Brumos Racing Car set a world record for its class at the 2023 Pikes Peak International Hill Climb, demonstrating the endless recycling potential of 3D printing.

October 2023

Copper and Steel, Together at Last

By functionally grading two materials together, researchers deposit stainless steel on top of a pure copper alloy during 3D printing. This novel approach has the potential to help the tooling industry improve thermal performance in molds and dies without losing mechanical performance.

November 2023

It’s Electric! (Boogie Woogie Woogie)

Using additive manufacturing and compression molding, a full-scale Electric Vehicle (EV) Battery Enclosure is made from a mold less than half the size of the final product. Making parts larger than the manufacturing equipment could help companies become part of the manufacturing supply chain with minimum investment.

December 2023

A Polarizing Discovery

Magnets used in electric motors are printed for the first time and achieve up to 6,000 RPM in a 9kW motor. This technology demonstrates the feasibility of a new hybrid manufacturing process, the capability of tuning magnets for electric motors, and controlling the structural stability of the motor components.

December 2023

Steam Power in the 21st century?

Researchers at MDF became the first to 3D print large rotating steam turbine blades, weighing over 25lb, for generating energy in power plants. Traditionally, the blades are forged overseas and take about 8 months to arrive in the US. However, the team at MDF prints the blades in 12 hours.

February 2024

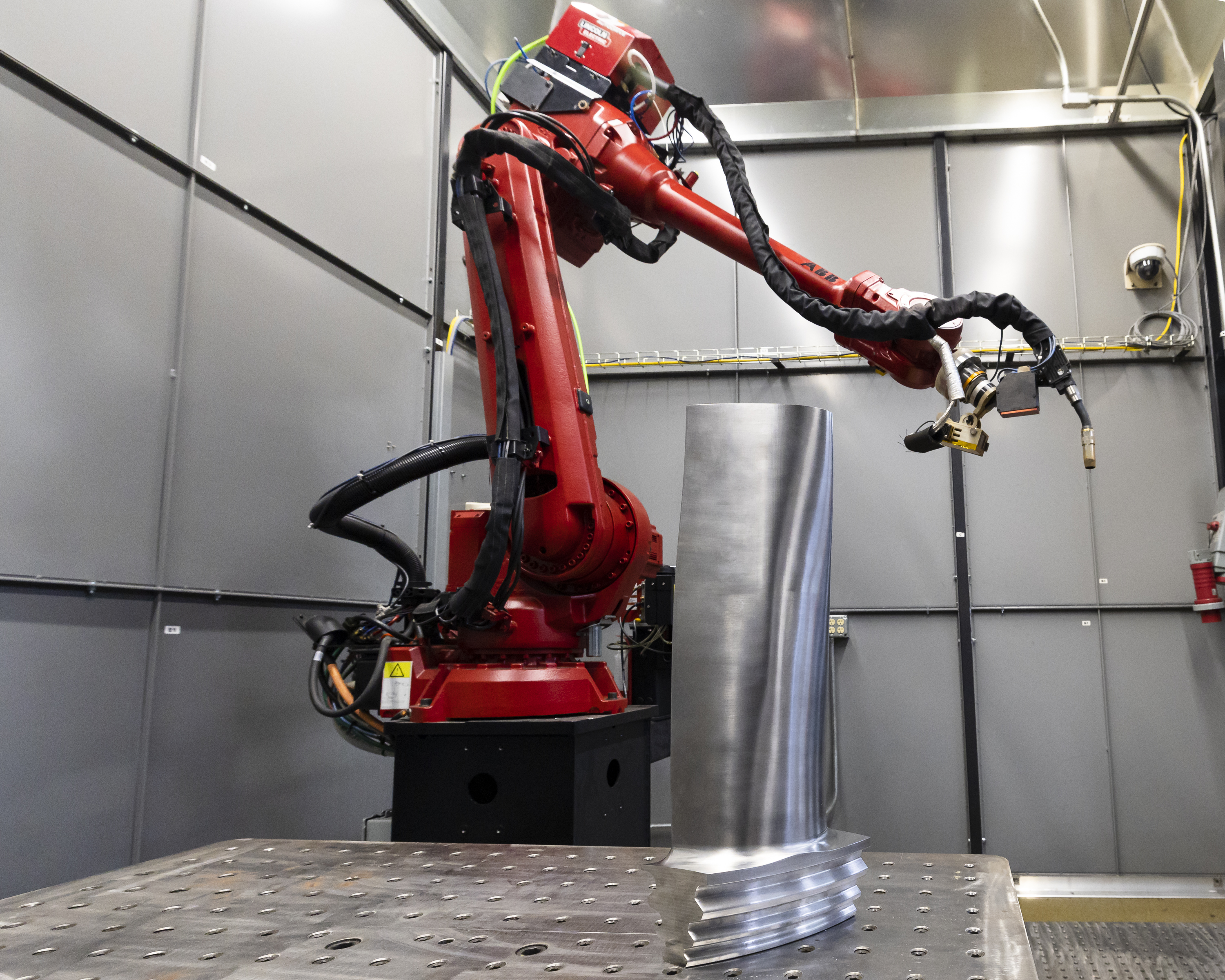

100lb per Hour Deposition Rate

Researchers demonstrate the ability to 3D print 100lb of metal per hour in complex, geometric shapes. This advancement is another step toward significantly lowering the time and money needed to produce large-scale metal printing projects for industries such as ship and pipe building.

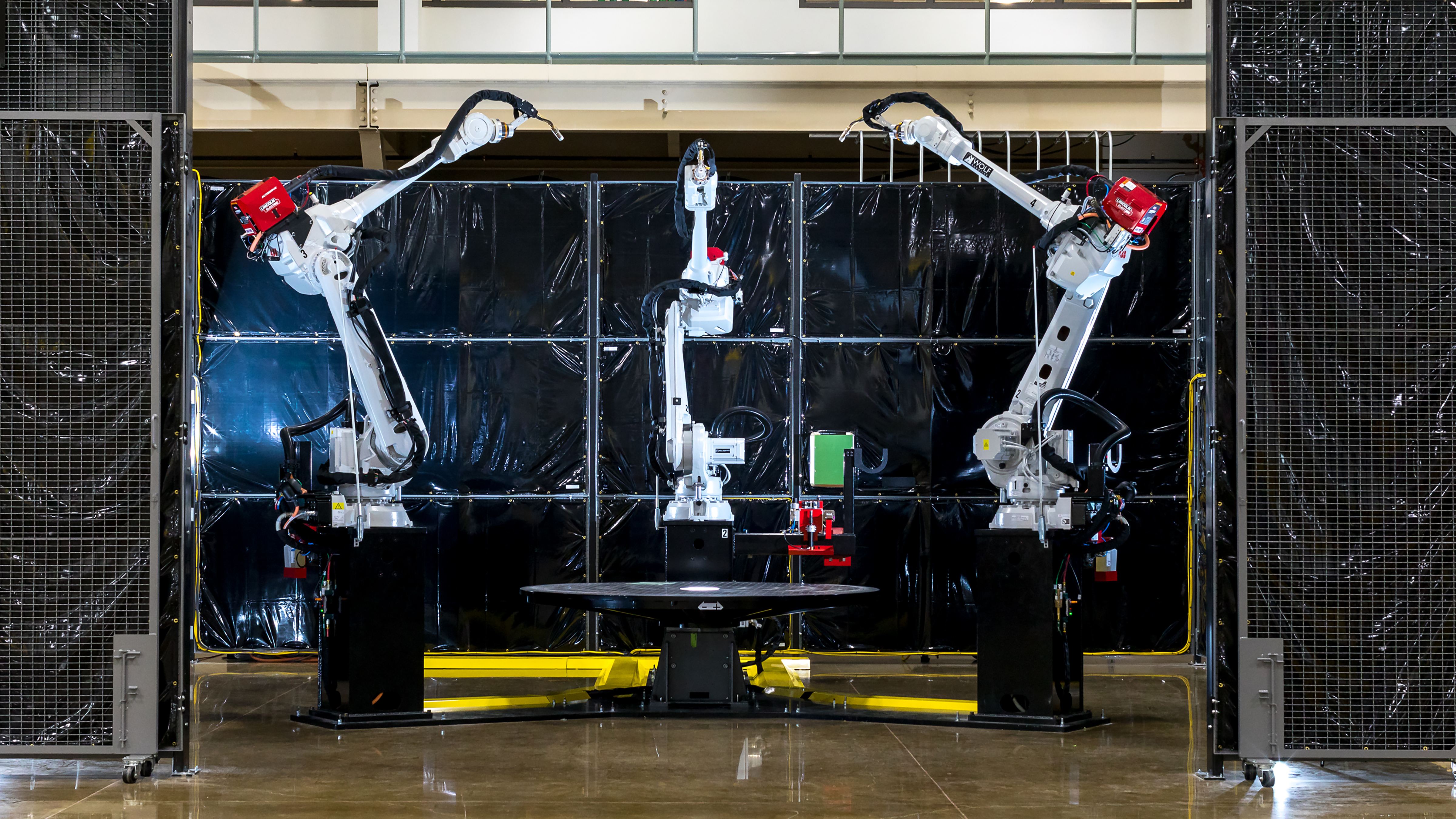

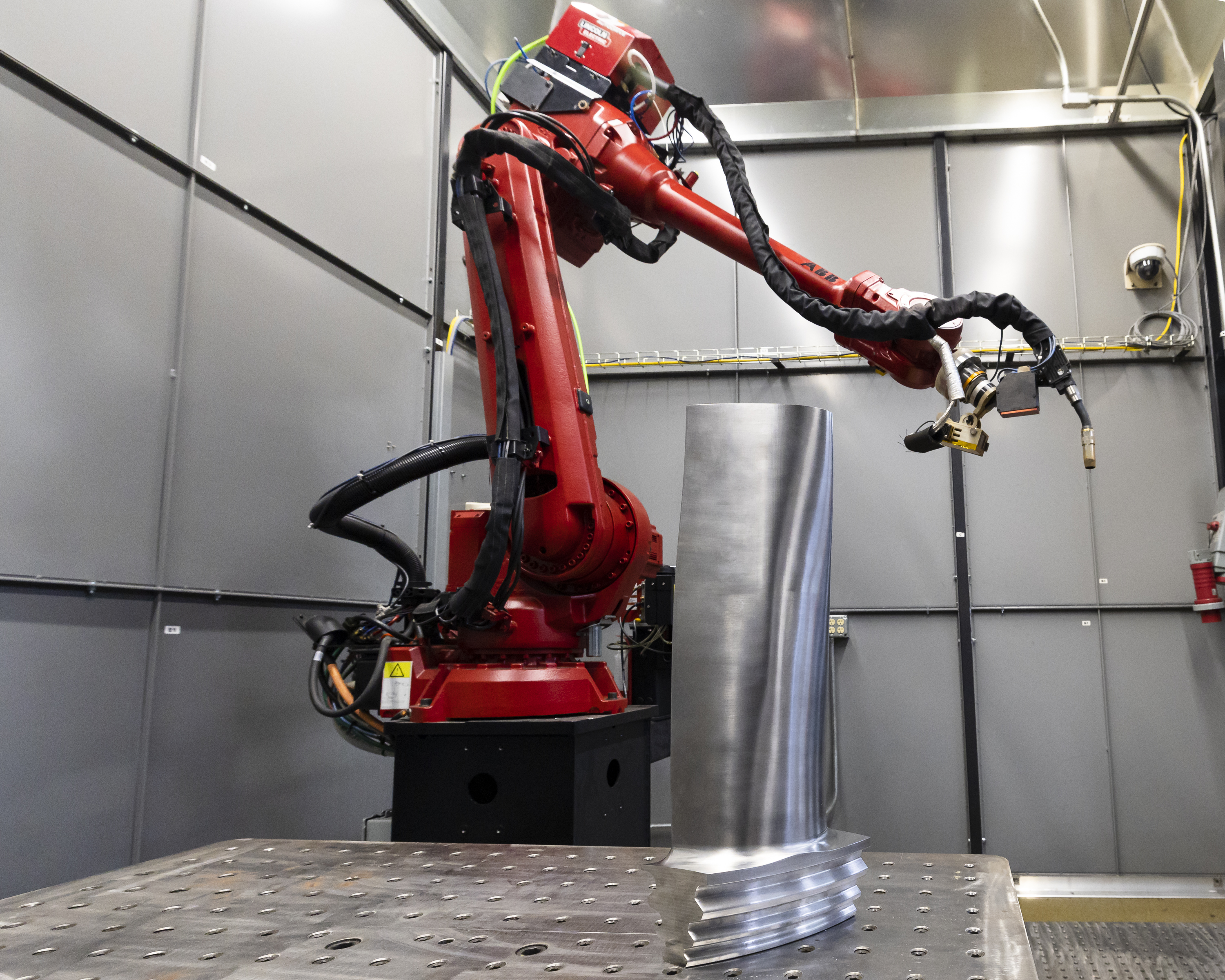

March 2024

HIP for Hydro

A wire arc manufacturing robot known as MedUSA is used to print a 900lb hydropower impeller can, which will be filled with metal powder and placed in a hot isostatic press (HIP) to solidify the material. Ordinarily, producing such cans takes months, but MedUSA completes it in just 46 hours.