New method could enable advances in energy, electronics and aerospace

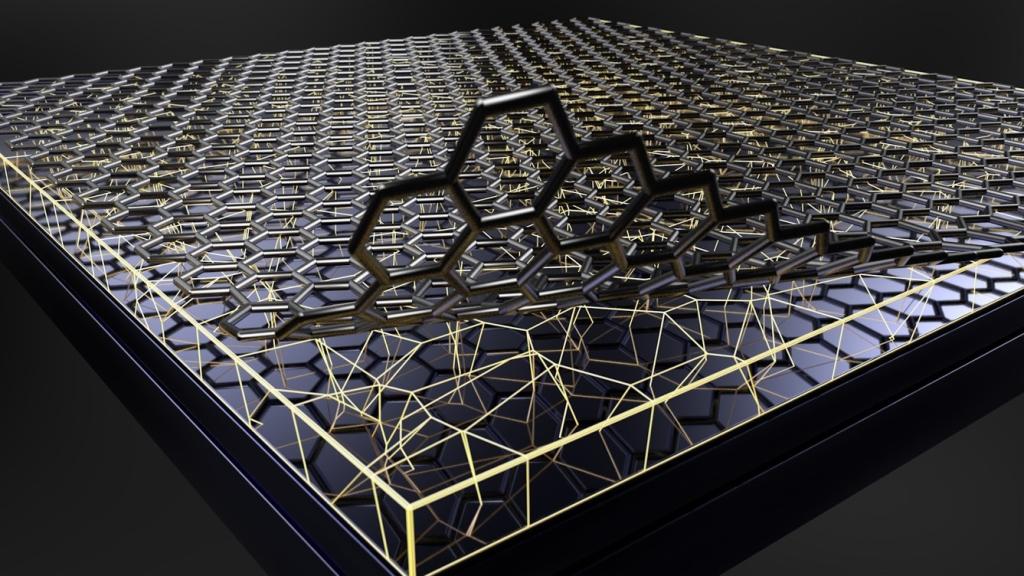

Researchers demonstrated that stainless steel and other metal alloys coated with hexagonal boron nitride, or hBN, exhibit non-stick or low-friction qualities along with improved long-term protection against harsh corrosion and high-temperature oxidation in air.

Metal alloys — mixtures of two or more metals — are created to be strong, durable and resistant to corrosion or oxidation. By adding coatings, or “armor,” to make those materials even tougher, scientists could enhance existing products and enable the creation of new, innovative ones.

For example, armoring may boost the ability of solar panels to conduct heat and resist environmental factors. Additionally, it allows semiconductors to maintain proper operating temperature, and aerospace turbine blades to guard against wear, reduce friction and withstand hot conditions.

The hBN coatings are produced from a combination of solid boron sources and molecular nitrogen by using a process called atmospheric pressure chemical vapor deposition.

“This synthesis technique addresses scalability issues such as cost and process safety in applications where those aspects have been problematic,” said ORNL’s Ivan Vlassiouk, who led the study. “Besides providing a versatile protective layer for steels and metals, using this process to synthesize single- and few-layer hBN for emerging two-dimensional electronic and photonic devices could improve their performance.”