Process contains leaks, improves thermal performance in buildings

Oak Ridge National Laboratory researchers have developed a novel way to encapsulate salt hydrate phase-change materials within polymer fibers through a coaxial pulling process. The discovery could lead to the widespread use of the low-carbon materials as a source of insulation for a building’s envelope.

Environmentally friendly salt hydrates can function as a thermal battery, providing heating and cooling by storing and releasing energy when changing from solid to liquid. The challenge to integrating them into walls and roofs is how they are enclosed to prevent leaking.

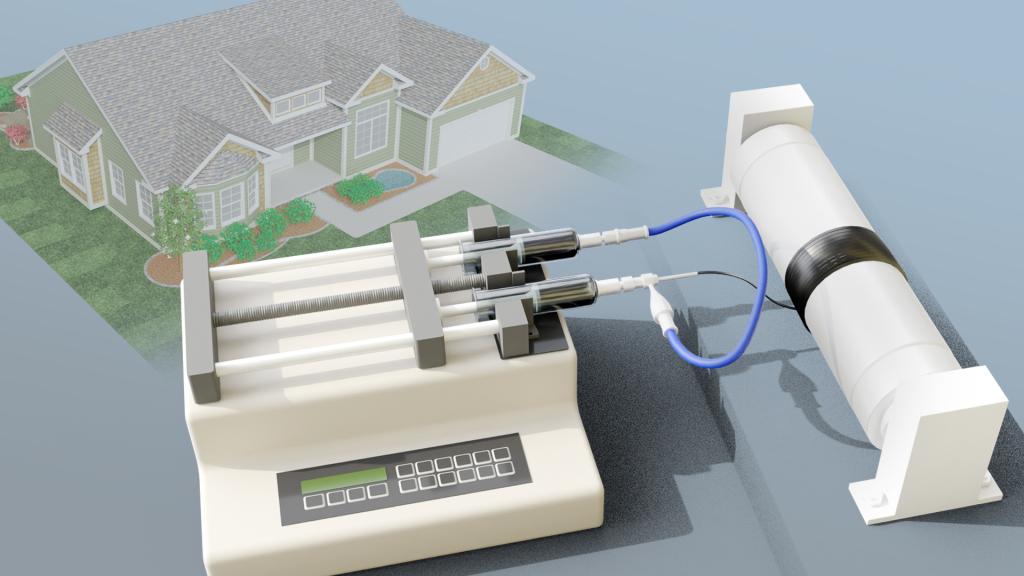

By using a coaxial technique, polymer and salt were pulled together in one direction to form core-shell fibers that contain a salt core and polymer shell.

“Coaxial pulling lowers the cost of encapsulation and offers better thermal conductivity and energy density, all while being easy to reproduce and scale up,” said ORNL’s Jaswinder Sharma. “The fibers are flexible and can be seamlessly incorporated into current building materials and products.”