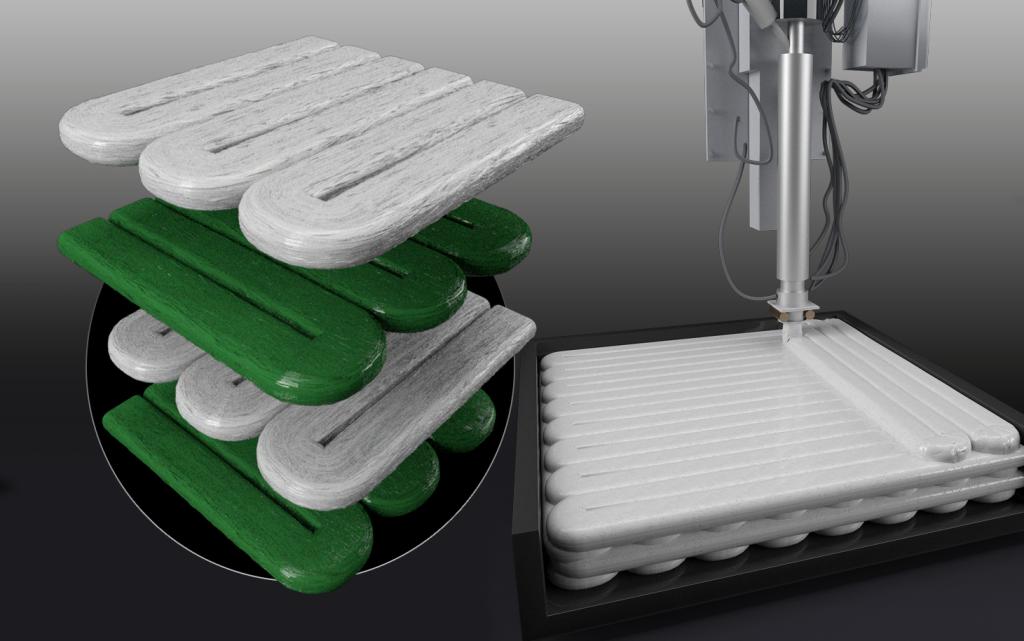

Oak Ridge National Laboratory researchers combined additive manufacturing with conventional compression molding to produce high-performance thermoplastic composites reinforced with short carbon fibers. Their approach demonstrates the potential use of large-scale multimaterial preforms to create molded composites.

In a study, researchers used ABS polymer, filled with carbon and glass fibers, in three manufacturing processes: additive, extrusion compression molding and the combined approach of additive and compression molding. The team analyzed mechanical properties of the resulting composite samples.

“We found that this integrated process showed substantial improvement in mechanical properties due to high fiber alignment and reduced porosity,” ORNL’s Vipin Kumar said. “Our demonstration proved that multimaterials can be deployed for the production of the plastic preforms industry needs to make the composites for aviation, transportation, defense and aerospace applications.”

Further research will include developing the system to be able to use long or continuous carbon fibers for enhanced strength.