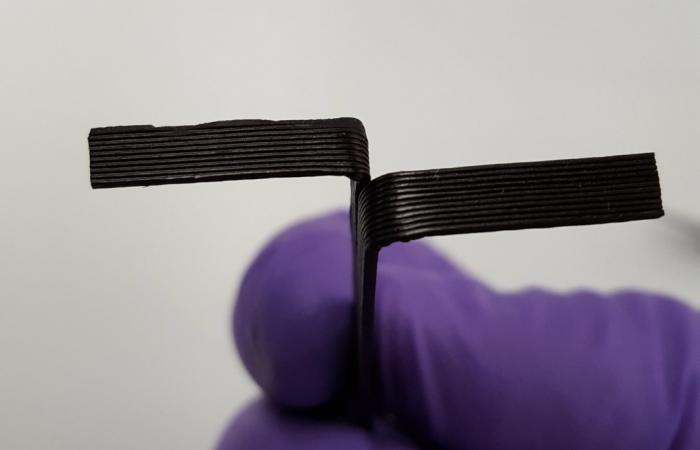

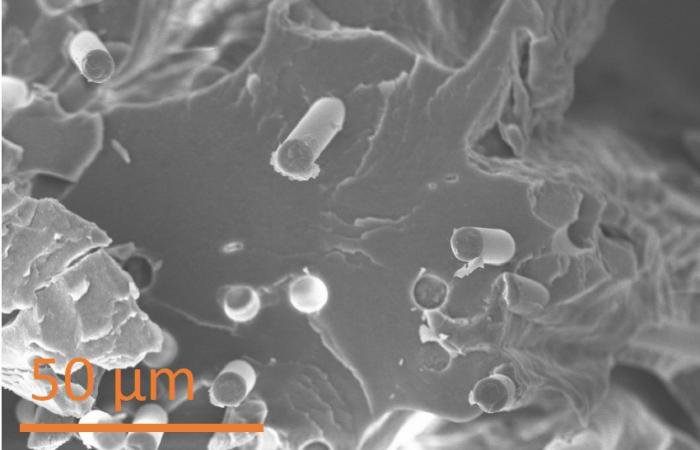

July 2, 2018—A scalable processing technique developed by Oak Ridge National Laboratory uses plant-based materials for 3D printing and offers a promising additional revenue stream for biorefineries. Scientists created a new material with excellent printability and performance by tapping into lignin—a key component of plant cell walls that provides sturdiness. Lignin is a current byproduct of the biofuels process that could become a valuable coproduct with this new use. The method combines lignin, rubber, carbon fiber and acrylonitrile butadiene styrene, or ABS—commonly used in plastic toys—to 3D print structures with 100 percent improved weld strength between the layers over ABS alone. “To achieve this, we are building on our experience with lignin during the last five years,” said ORNL’s Amit Naskar. “We will continue fine tuning the material’s composition to make it even stronger.” The research team published details about the patent-pending process in Applied Materials Today.

Topics:

Media Contact

Kimberly Askey

, Communications Coordinator, Biological and Environmental Systems Science Directorate

, 865.576.2841

|

ASKEYKA@ORNL.GOV