November 1, 2018 — Scientists from AK Steel Corporation are using neutrons at Oak Ridge National Laboratory’s Spallation Neutron Source to discover how different manufacturing processes will affect the performance of the company’s new AHSS, or advanced high strength steel, called NEXMET® 1000. Neutrons, unlike electrons or X-rays, are highly penetrating, non-destructive and sensitive to lighter elements, making them an ideal probe for this novel category of steel materials. “The VULCAN instrument at SNS provides information about the crystal structure of AHSS during different stages of the stamping process that we cannot get anywhere else in the United States,” said Wei Wu of AK Steel. “This data will be vital to improving our manufacturing methods and will make it easier to quickly identify the best new materials to blend with NEXMET® 1000 to produce lighter, safer and more durable automotive components.”

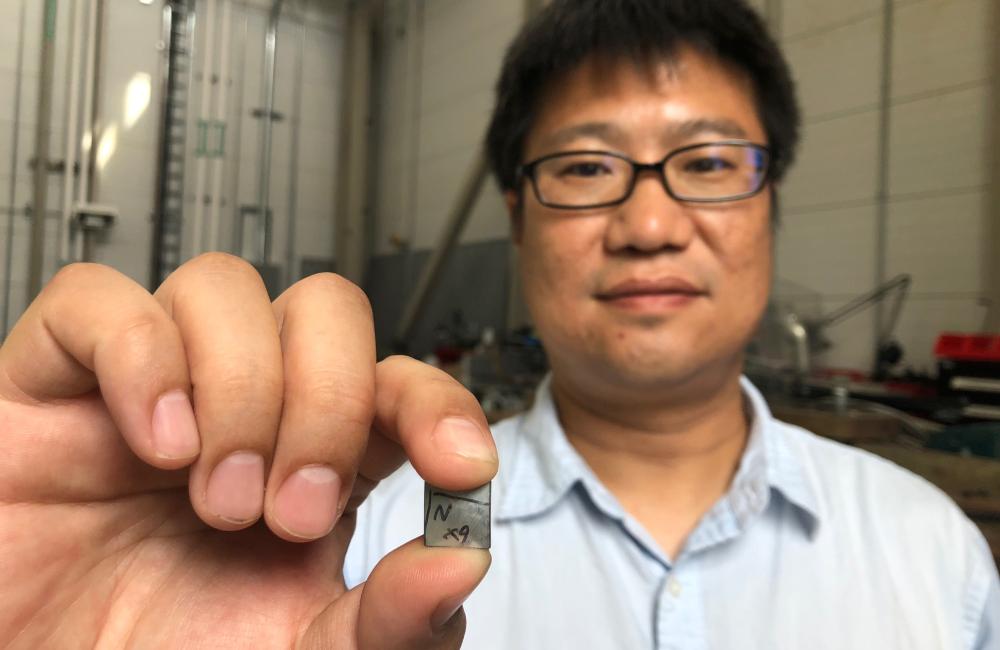

AK Steel Corporation scientist Wei Wu holds a sample of the company’s new advanced high strength steel. Wu is using neutrons to study how the material is affected by various manufacturing processes to produce automotive components that improve fuel efficiency, last longer and are safer. Credit: Kelley Smith/Oak Ridge National Laboratory, U.S. Department of Energy.

Topic: