April 2, 2018 - Oak Ridge National Laboratory has partnered with FCA US LLC and casting manufacturer Nemak to develop a new cast aluminum alloy for engine cylinder heads, which could lead to more fuel-efficient internal combustion engines. Using neutron diffraction at ORNL’s Spallation Neutron Source, they can compare the residual stress levels of new materials and existing alloys. “Understanding residual casting stresses of an engine component, particularly in areas of high cyclic stress and temperature, provides opportunities to improve both performance and durability,” said Chris Glaspie of FCA US. Future engines made from these new alloys may also reduce carbon dioxide emissions without sacrificing vehicle performance. Studying residual stresses at ORNL brings the team one step closer to adapting the new alloys for commercial use. This partnership is part of a Department of Energy Cooperative Research and Development Agreement. - By Elizabeth Rosenthal

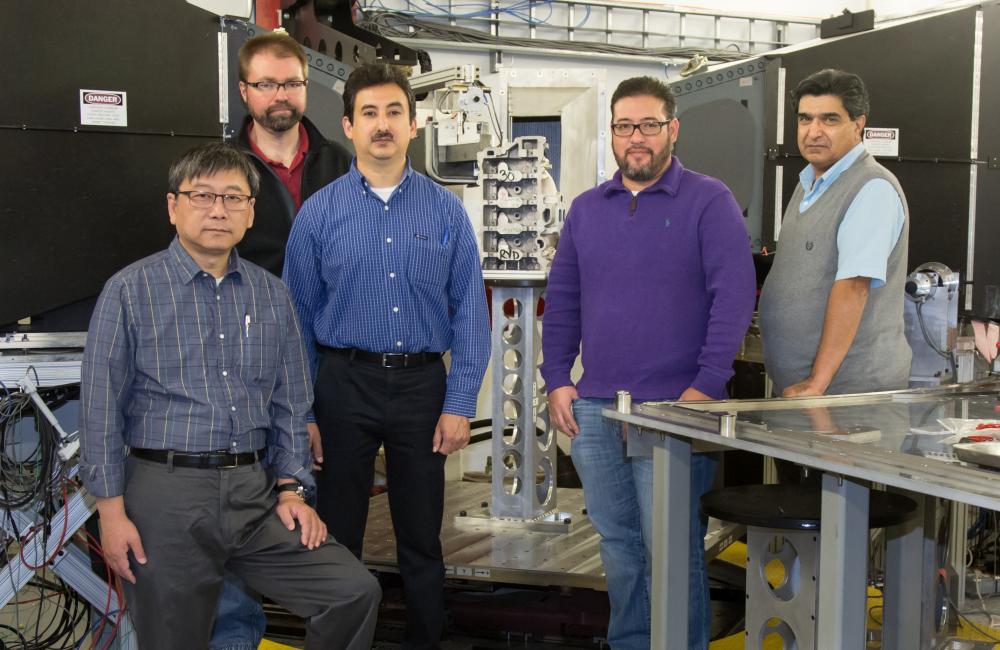

From left, researchers Yi Liu from FCA US; Thomas Watkins with ORNL; Andres Rodriguez and Alejandro Gonzalez of Nemak; and Seyed Mirmiran with FCA US are part of a team using neutrons to compare residual stresses in engine cylinder heads made from different cast aluminum alloys. Credit: Genevieve Martin/Oak Ridge National Laboratory, U.S. Dept. of Energy