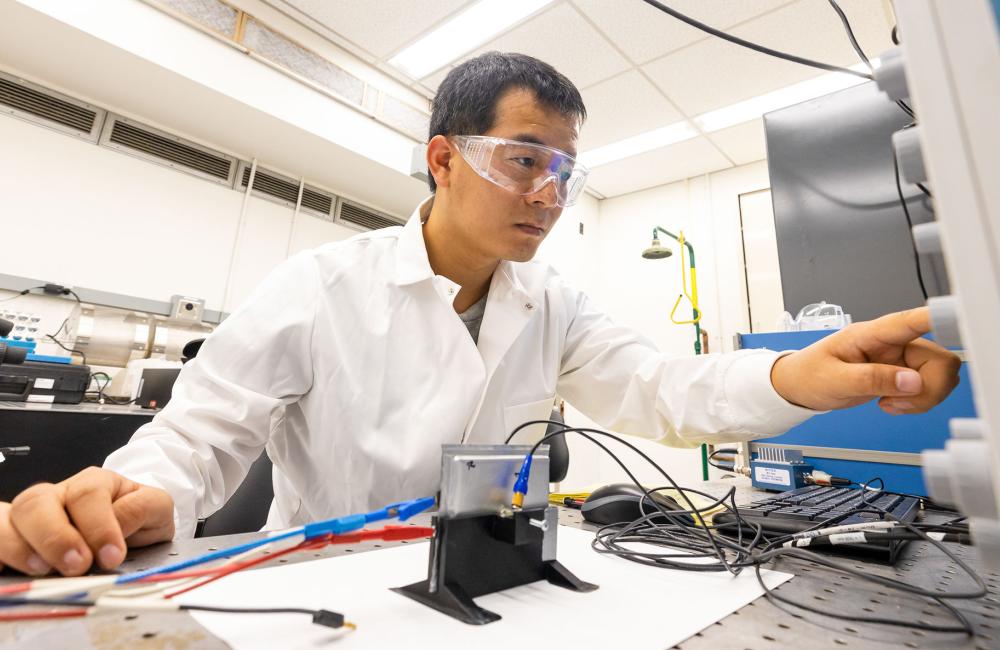

Researcher Sun Hongbin examines material changes to a battery made in the DOE’s Battery Manufacturing Facility using an ultrasound sensor. Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

Scientists at Oak Ridge National Laboratory are using ultrasounds — usually associated with medical imaging — to check the health of an operating battery. The technique uses sensors as small as a thumbnail, which could be attached to a lithium-ion battery inside a car.

Companies can use this technology to immediately learn which batteries are healthy enough to be resold. “We are combining expertise at ORNL’s Battery Manufacturing Facility with ultrasound measurement expertise to identify good batteries that can be reused, reducing waste,” said ORNL’s Hongbin Sun.

Ultrasound waves can continuously monitor battery material property and structural changes while the battery charges or discharges. Sun’s team, including BMF staff and experts in ORNL’s Nuclear Energy and Fuel Cycle Division, identified the best testing methods to correlate ultrasound results with a battery’s state of charge. “This is key to measuring battery life, performance and safety,” Sun said.