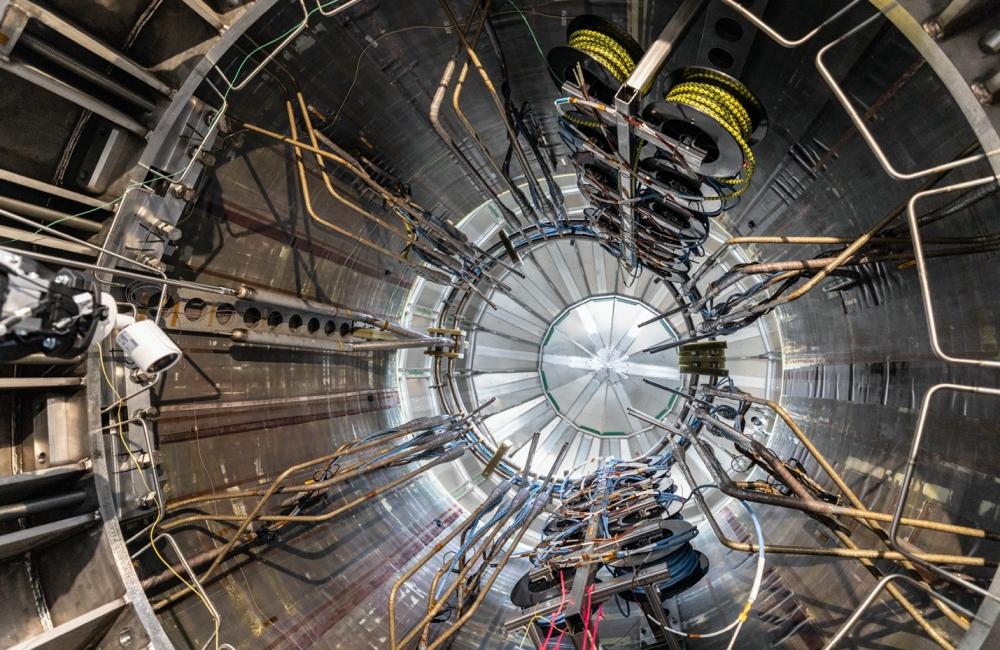

The interior of a central solenoid module shows the extensive network of helium piping needed to keep the superconducting magnet at 4 degrees Kelvin. US ITER is managing the fabrication of magnet modules at General Atomics in Poway, CA. Photo credit: General Atomics

As Oak Ridge National Laboratory’s Material Plasma Exposure eXperiment (MPEX) prepares for the start of fabrication, ORNL’s Phil Ferguson credits US ITER staff for sharing hard-earned expertise to help jump-start the design of the MPEX superconducting magnet system.

“Having the US ITER magnet experts here at ORNL allowed them to share their expertise, which we integrated into the design of the MPEX magnet system,” said Ferguson, MPEX project director. “That gave us a boost in our starting point, helped us avoid making mistakes, and has enabled us to better deliver on budget and on schedule.”

MPEX is part of ORNL efforts to realize one of the greatest engineering challenges of the 21st century: delivering energy from fusion. Scheduled to start assembly in 2023, MPEX is a next-generation linear plasma device that will provide a testing chamber for scientists to study how plasma interacts with new materials being developed that can withstand the extreme conditions of fusion power plants. Fusion environments can have temperatures hotter than the Sun and magnetic fields hundreds of thousands of times stronger than the Earth’s.

“What makes MPEX unique is that researchers will easily be able to swap different materials in and out to analyze them to see how they will hold up under fusion prototypic conditions,” said Robert Duckworth, group leader for ORNL’s Fusion Technology, who is leading the multi-disciplinary MPEX magnet team. “This is something that’s not practical to do in the existing experimental tokamaks we have today.”

US ITER has already delivered superconductors to France for the toroidal field ITER magnet system and is now managing fabrication of the central solenoid, an 18-meter-tall, 1,000 ton, 13.1 Tesla superconducting magnet composed of six stacked modules. Behind these accomplishments are years of experience in resolving engineering challenges for fusion magnet systems. The ITER tokamak is now under assembly, and the first coils of the poloidal field magnet system are in place.

“We had engineering challenges every step of the way, which were critical to resolve because of the role of the central solenoid magnet in a fusion reactor,” said David Everitt, US ITER central solenoid systems manager. “The central solenoid is the heartbeat of a tokamak. It kicks the whole thing off, driving the plasma current and then helping to contain the plasma.”

In designing the MPEX magnet system, researchers have learned some critical tips from their US ITER colleagues.

“A key lesson learned shared by US ITER staff with us was the importance at the earliest stages of design to focus first on how the magnet system will be integrated with other MPEX systems to deliver the spectrum of conditions of interest to the fusion materials community. They found this integrated approach to be key to avoid setbacks and cost overruns,” Duckworth said.

MPEX also benefited from US ITER’s guidance on quality control, documentation, regulatory requirements and the establishment of an advisory board, as well as on the level of detail needed for the base design before discussing plans with vendors for procurement and fabrication.

With the initial design stage complete, MPEX staff are now working closely with industry to finalize contracts for fabrication of the magnet system. As work moves forward, the MPEX and US ITER teams expect their bond to continue. Once MPEX is up and running, it will support fusion materials research to prepare for a fusion pilot plant.

“The atmosphere of collaboration here at Oak Ridge is why I appreciate the opportunity to work at this lab,” Duckworth said. “The expertise and willingness of the staff to share lessons learned, along with the tools and facilities available at the lab, are what make this collaboration possible – and are what make it fun.”

U.S. contributions to ITER and MPEX are sponsored by the Department of Energy’s Office of Science and managed by UT-Battelle at Oak Ridge National Laboratory in Tennessee, with contributions to ITER by partner labs Princeton Plasma Physics Laboratory and Savannah River National Laboratory. For more information, see https://usiter.org. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit https://www.energy.gov/science.

— Amy Reed