- Supercomputing

- Energy Sciences

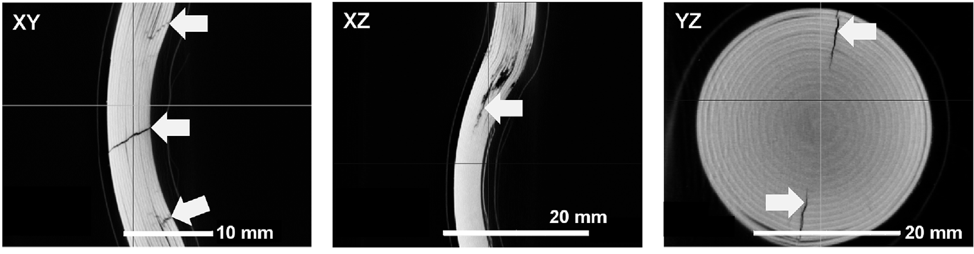

The Science/Achievement: This work investigates mechanical behavior of Li-ion batteries for electric vehicles (EV). While there is a significant amount of accumulated knowledge regarding mechanics of structural materials for modern vehicles, with a good selection of constitutive models available, the same cannot be stated regarding battery packs in EVs, despite the fact that these are essentially structural components and are part of the chassis. This work makes a step towards closing this gap. EV battery modules (from Ford Focus EV) were subjected to external mechanical loading to investigate mechanical behavior and failure leading to short circuit. A novel experimental setup was designed for this purpose which allowed for prices control of loading conditions. Failure model was proposed and implemented in finite element (FE) analysis of the battery with good predictive capability. The study utilized X-Ray Computed Tomography (XCT) for non-destructive evaluation of batteries to reveal internal distribution of deformation and failure mechanism.

Significance and Impact: This is a first (to our knowledge) investigation of battery deformation under mechanical loading with formulation and application of failure criterion to predict internal short circuit. The work is sponsored by the National Highway Traffic Safety Administration (NHTSA) with the goal to identify safety limitations of EV battery packs, their response to deformation, and development of models to predict their behavior under mechanical loading. Based on a thorough investigation we determined that the failure criterion should be based on strain; this failure criterion was postulated for separator – an internal porous membrane inside the battery cell that separates positive and negative electrodes from creating short circuit. The criterion was integrated into finite element analysis of the battery module and the results followed experiments well, indicating good predictive capability of the model. The team also investigated effect of passive components in battery module, such as cooling plates and module enclosure. It was determined that presence of cooling plates reduced the force of impact, which is a key finding related to EV crash safety, as it allows for future design of battery packs with built-in multifunctionality.

Research Details

- Battery cells were extracted from Ford Focus EV battery packs and placed as stacks into specially designed setup to simulate deformation of battery modules in a MTS servohydraulic load frame. Prior to the testing the cells were completely discharged.

- The cell stacks were deformed by a spherical indenter (50 mm in diameter) until internal failure resulted in short circuit which was registered simultaneously with force-displacement data acquisition.

- XCT was performed on deformed cells using Zeiss Versa 520 X-Ray system with a tungsten source.

- FEA was performed using LS Dyna software. Plane stress anisotropic model was applied to separator with critical first principal strain serving as a failure criterion.

Facility: Equipment of the Mechanical Properties and Mechanics group was used in testing battery modules.