Invention Reference Number

Related Links

Aluminum alloys are increasingly utilized in transportation, aerospace, and defense sectors due to their lightweight properties. Additive manufacturing (AM) offers potential for producing complex designs with these alloys, but many traditional aluminum alloys are not suitable for AM due to issues like hot-cracking and poor high-temperature performance. There is a significant need for aluminum alloys that perform well under AM conditions and retain mechanical strength at high temperatures.

Description

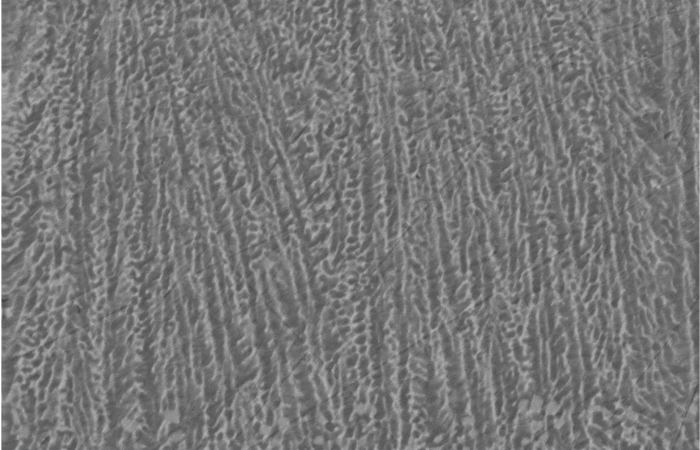

This technology relates to an aluminum alloy composition specifically designed for additive manufacturing. The alloy consists of aluminum, cerium (Ce), and nickel (Ni), and may include other minor elements such as manganese (Mn), iron (Fe), magnesium (Mg), zirconium (Zr), silicon (Si), and chromium (Cr). The combination of these elements forms intermetallic phases like Al23Ni6Ce4, Al11Ce3, Al7Ni2Ce, Al20Mn2Ce, and Al3Ni, which provide superior mechanical properties and resistance to hot-cracking.

Benefits

- High-temperature strength: Retains mechanical strength at temperatures between 250°C and 450°C.

- Resistance to hot-cracking: Suitable for AM processes with minimal defects.

- Complex geometries: Supports the creation of intricate designs not achievable with conventional methods.

- Mechanical properties: Exhibits high yield strength, ultimate tensile strength, and elongation both in as-fabricated and hot isostatic pressed conditions.

Applications and Industries

- Aerospace: Components such as turbine blades, heat exchangers, and structural parts.

- Automotive: Engine parts, pistons, cylinder heads, and turbocharger manifolds.

- Defense: Lightweight, high-strength components for various defense applications.

- Industrial machinery: Parts requiring high strength and heat resistance.

Contact

To learn more about this technology, email partnerships@ornl.gov or call 865-574-1051.