Invention Reference Number

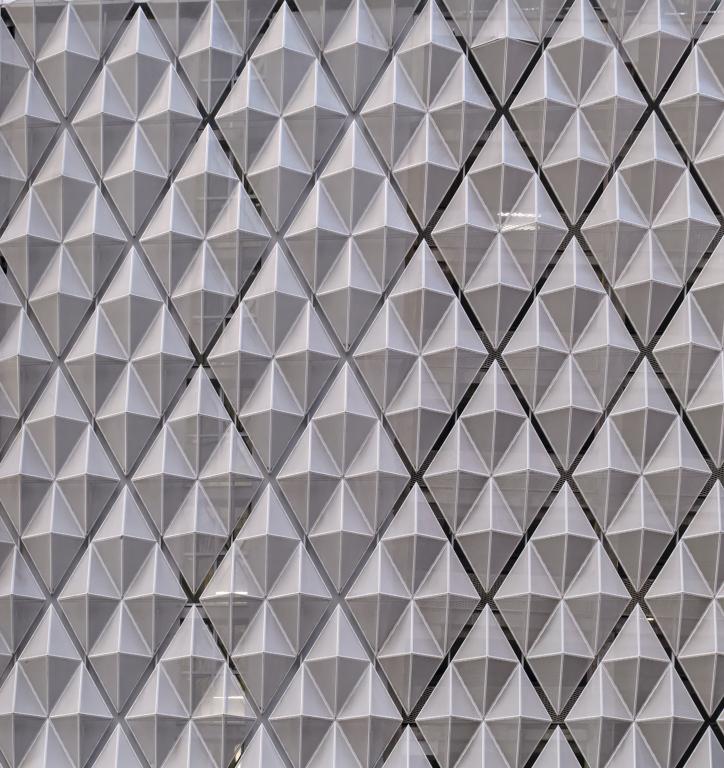

High and ultra-high vacuum applications require seals that do not allow leaks. O-rings can break down over time, due to aging and exposure to radiation. Metallic seals can damage sealing surfaces, making replacement of the original seal very difficult. This technology is a double diamond metallic seal for these applications. The double diamond seal is made of a soft, ductile metal such as aluminum or copper, and is placed between two opposing sealing surfaces. Pressure applied to the opposing sealing surfaces compresses the tips of the diamond points by deformation and forms two separate seals.

Description

The double diamond seal creates two redundant sealing surfaces at the same time, with one continuous inner sealing surface and one continuous outer sealing surface. The seal consists of an inner diamond ring and an outer diamond ring that would span the damaged area and provide redundant sealing, plus mechanical stability. The "top" and "bottom" triangular points oppose each other for each of the sealing surfaces. The double diamond seal is placed between two opposing sealing surfaces, and then pressure is applied to the opposing sealing surfaces to compress the tips of the diamond points by deformation and form two separate seals. It is suitable for ultra-high vacuum and potentially for aerospace or outer space. It would also be suited to hermetic sealing against other gases and liquids, and would be suitable for a broad temperature range and potentially cryogenic temperatures.

Benefits

- Metallic seal suitable for radiation environments and broad temperature ranges

- Creates two seals at once for high-vacuum applications

- Can straddle damaged existing surfaces to allow successful sealing where it would not have been possible

Applications and Industries

- High- and ultra-high vacuum applications

- High purity sealing

- Aerospace

Contact

To learn more about this technology, email partnerships@ornl.gov or call 865-574-1051.