Metal Deposition

Additive manufacturing can be used to create metal components by locally melting metal powder or wire to form the part directly from a computer generated design file. Metal additive manufacturing technologies can significantly improve manufacturing energy efficiency by increasing material utilization and minimizing scrap material associated with component fabrication. Elimination of geometrical constraints associated with conventional manufacturing technologies such as casting and machining can result in components that fulfill all of the functional requirements but weigh significantly less than those of conventional design.

Current research objectives are to improve the process reliability of electron beam melting (EBM) technology through the utilization of in-situ process monitoring and closed loop control, expand EBM technology to new materials systems, specifically Ni based superalloys, and to validate microstructure and properties of Ti-6Al-4V materials fabricated with increased deposition rate. In-situ process monitoring techniques such as high speed video imaging and high speed infrared thermography developed previously will be utilized to understand the effects of process variables on resulting microstructure and mechanical properties. In-situ process monitoring will be performed on Inconel materials as well to understand porosity and defect formation during the electron beam melting process. The process routines developed previously for Inconel will be expanded to include uniform energy input over increasingly complex geometrical features. We will also verify and validate the new electron column and filament using the Arcam Q10 system. It will be determined if the new technology is capable of producing material with similar microstructure and properties to previously studied Ti-6Al-4V material fabricated with the technology.

Polymer Deposition

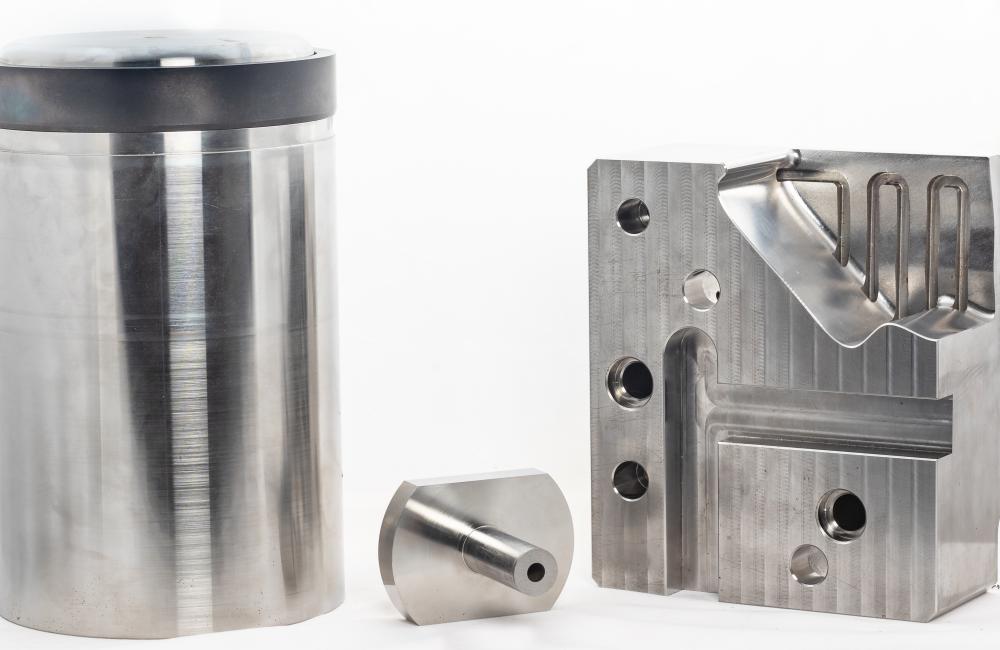

Polymer additive manufacturing can enable the rapid manufacture of lightweight, complex components and impact a broad spectrum of manufacturing industries. Examples include the tool and die industry (rapid, low-cost tooling), lightweight components for the transportation industry (automotive and aerospace), low-cost components for the energy industry. Current objectives are focused on developing composite materials, process monitoring and closed loop feedback control systems to increase the mechanical properties and production quality of fused deposition modeling (FDM) components.

The largest portion of additive manufacturing systems use polymers as the feedstock material, so advancements in polymer additive manufacturing can have a rapid impact on applications due to the large number of systems in the marketplace. To date, the primary market for additive manufacturing with polymers has been prototyping. There are three fundamental R&D challenges that are limiting use of polymer additive manufacturing for end use products. First, the material properties (strength and stiffness) are significantly lower than conventional materials. By doubling the specific strength of the polymer feedstock materials through the development of new polymers or adding fillers such as glass and carbon fiber to the material, the material properties can approach those of medium strength aluminum alloys, opening up numerous end use applications. Second, the layer-wise deposition lowers the effective strength in the vertical build direction (Z-direction). Detailed thermal analysis and several process modifications are being pursued to increase Z-direction strength. Finally, all polymer additive systems run open loop. If something goes wrong during the build, the system has no knowledge and continues without correcting or stopping the build. Efforts are underway to address in-situ feedback and control to ensure part quality and fault detection.

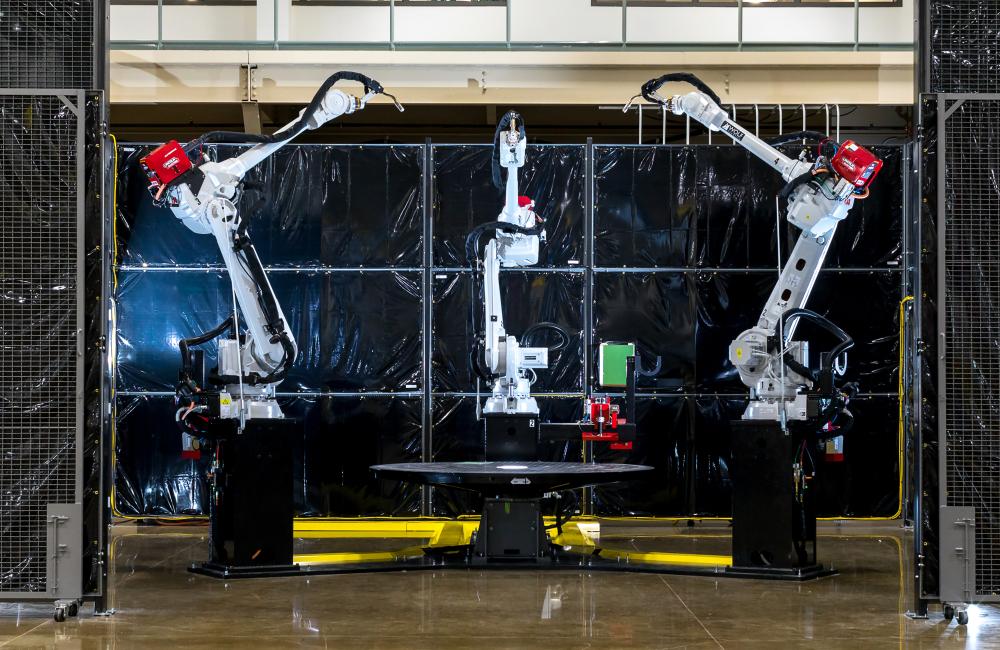

Recent work has been undertaken to capture opportunities for decreasing the cost and increasing the efficiency through large scale additive manufacturing systems. Current AM systems manufacture parts in sizes greater than 1 cubic meter with deposition rates of approximately 100 pounds/hour. The focus of this new work will be the development of materials, processes and controls that can enable the manufacture of parts that are one to two orders of magnitude greater size than the state of the art at deposition rates that are two orders of magnitude greater than the state of the art.