Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Scientists at ORNL have invented a coating that could dramatically reduce friction in common load-bearing systems with moving parts, from vehicle drive trains to wind

Anne Campbell, an R&D associate at ORNL, has been selected for an Emerging Professional award from ASTM International.

Anne Campbell has been selected as a topical editor for a special issue of the journal Frontiers in Nuclear Engineering, titled “Women in Nuclear Engineering Research.”

Anne Campbell, an R&D associate in ORNL’s Materials Science and Technology Division since 2016, has been selected as an associate editor of the Journal of Nuclear Materials.

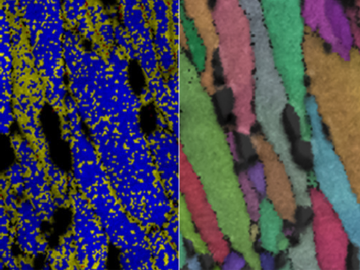

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

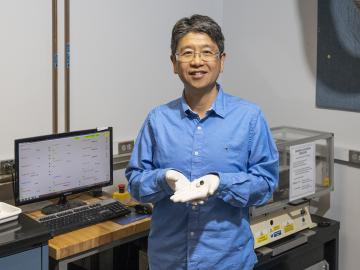

The Department of Energy’s Oak Ridge National Laboratory has exclusively licensed battery electrolyte technology to Safire Technology Group.

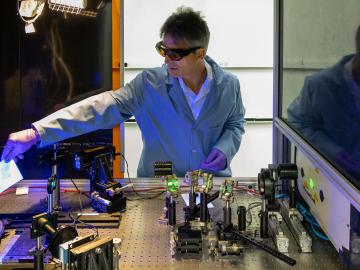

A multidisciplinary team of scientists at ORNL has applied a laser-interference structuring, or LIS, technique that makes significant strides toward eliminating the need for hazardous chemicals in corrosion protection for vehicles.

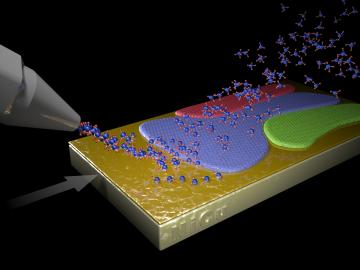

A new method to produce large, monolayer single-crystal-like graphene films more than a foot long relies on harnessing a “survival of the fittest” competition among crystals.