In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

In fiscal year 2023 — Oct. 1–Sept. 30, 2023 — Oak Ridge National Laboratory was awarded more than $8 million in technology maturation funding through the Department of Energy’s Technology Commercialization Fund, or TCF.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Scientist-inventors from ORNL will present seven new technologies during the Technology Innovation Showcase on Friday, July 14, from 8 a.m.–4 p.m. at the Joint Institute for Computational Sciences on ORNL’s campus.

Nine engineers from ORNL visited 10 elementary and middle school classrooms in three school districts during National Engineers Week, Feb.

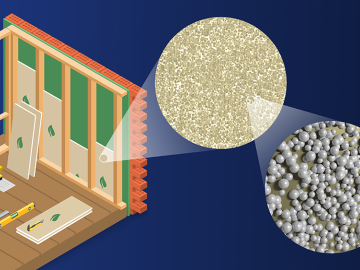

Scientists at ORNL developed a competitive, eco-friendly alternative made without harmful blowing agents.

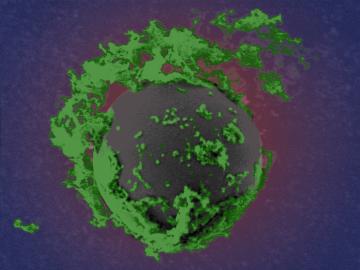

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

Five technologies invented by scientists at the Department of Energy’s Oak Ridge National Laboratory have been selected for targeted investment through ORNL’s Technology Innovation Program.

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

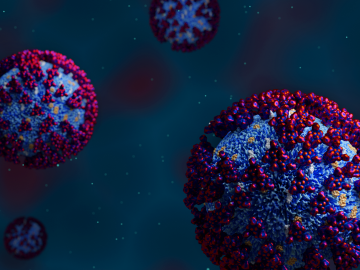

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron sc

Researchers at Oak Ridge National Laboratory demonstrated that an additively manufactured polymer layer, when applied to carbon fiber reinforced plastic, or CFRP, can serve as an effective protector against aircraft lightning strikes.