Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

R&D World magazine has announced the winners from their selection of finalists who will be recognized at the organization’s 60th awards ceremony on Nov. 17 in Coronado, California.

Established in 1963, the R&D 100 Awards, dubbed “the Oscars of Innovation,” annually recognize 100 accomplishments in research leading to new commercial products, technologies and materials from around the world notable for their technological significance. This year’s wins bring ORNL’s total R&D 100 Awards to 239 since the award’s inception.

"Each day, ORNL strives to deliver scientific breakthroughs for the benefit of society," ORNL Director Thomas Zacharia said. "The R&D 100 Awards are a tremendous recognition of the hard work and dedication required by our researchers to develop these impactful technologies."

Among nine ORNL finalists, the winning ORNL researchers and technologies include:

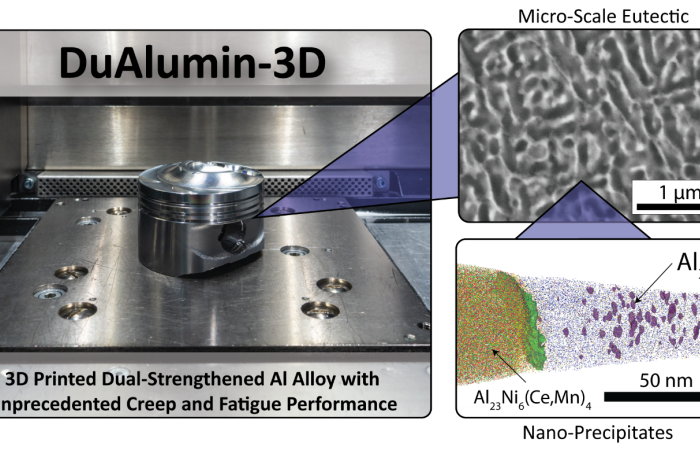

DuAlumin-3D: An Additively Manufactured Dual-Strengthened Aluminum Alloy Designed for Extreme Creep and Fatigue Resistance, developed by ORNL, General Motors and Beehive Industries.

In response to a need for more resilient, lightweight aluminum alloys, ORNL researchers designed DuAlumin-3D, an aluminum alloy with a combination of tensile, creep, fatigue and corrosion properties superior to all known cast, wrought and printable aluminum alloys.

DuAlumin-3D is designed to take advantage of the unique thermal conditions that occur during the laser additive manufacturing process. The alloy takes its name from dual strengthening mechanisms: a nanoscale microstructure that forms during printing and precipitates that form upon heat treatment. Because of these microstructural features, the alloy retains more than half its strength at high temperatures of 300 to 315 degrees and is stable up to 400 degrees C.

Funding for this project was provided by the Office of Energy Efficiency and Renewable Energy’s Vehicle Technologies Office and Advanced Manufacturing Office.

Principal investigators for this research include ORNL’s Alex Plotkowski, GM’s Qigui Wang and Beehive3D’s Jonaaron Jones; GM’s Andy Wang, Devin Hess, Dan Wilson and Dale Gerard; Beehive Industries’s Devon Burkle, Rachel Jones and Charles Stansberry; and ORNL’s Amit Shyam, Ryan Dehoff, Allen Haynes, Richard Michi, Sumit Bahl, Ying Yang, Larry Allard, Jon Poplawsky, Bill Peter, Derek Splitter and Jiheon Jun. The University of Tennessee’s Kevin Sisco also contributed to the development.

Gremlin: Adversarial Discovery of Weaknesses in Machine Learners, developed by ORNL.

Weaknesses in machine learning technology can have serious consequences, such as improperly trained facial recognition artificial intelligence yielding inaccurate identification. To improve machine learning, ORNL researchers developed Gremlin, a learning system designed to identify and address the worst-performing neural network feature sets.

Gremlin identifies problems within a machine learning system, often through inverting a model’s training metrics. For example, a model may be trained to drive a virtual autonomous car, so a simple training metric for that model might be maximizing the length of time before crashing; Gremlin would invert that metric to discover scenarios where the model crashes the soonest.

The system can then be used to update the model training data with more examples of those poor performing scenarios, and the model is retrained using that updated data.

Gremlin decreases time needed to address machine learning model weaknesses and can be scaled for application from laptop computers to machines like ORNL’s Summit supercomputer.

A flexible framework improving upon comparable systems, the technology can be used on machine learning models designed for most any application.

Funding for this project was provided by the Office of Energy Efficiency and Renewable Energy’s Vehicle Technologies Office and the DOE Office of Science’s Advanced Scientific Computing Research.

ORNL’s Mark Coletti led the development. ORNL’s Robert Patton and Quentin Haas also contributed to the development.

RapidCure: High-Speed Electron Beam Processing of Battery Electrodes, developed by ORNL. This technology also received the Silver Award in the Special Recognition: Green Tech category.

In typical lithium-ion battery electrode production, materials are mixed in N-Methyl-2-pyrrolidone, an organic solvent, to form a slurry during manufacturing. There are several drawbacks to this method: the solvent is toxic and explosive, the process requires long-drying ovens and solvents must be recovered after manufacturing.

To address the disadvantages of this production process, ORNL researchers developed a cleaner and more efficient method to manufacture electrodes. A high-speed electron beam essentially replaces the long-drying ovens to evaporate the solvent, serving as the energy source to chemically polymerize and crosslink small molecules into high molecular weight polymers.

Additionally, this technology produces electrodes faster — seconds to minutes compared with the solvent method — and reduces the energy and equipment necessary for manufacturing. When the process is complete, no recycling unit is required, unlike the mandatory recovery when using the solvent.

Funding for this project was provided by DOE’s Office of Energy Efficiency and Renewable Energy.

ORNL’s Zhijia Du led the development. ORNL’s Chris Janke, David Wood and Jianlin Li and Carrier Global's Claus Daniel also contributed.

SolidPAC: A Comprehensive Solid-State Battery Design Tool, developed by ORNL.

Solid-state batteries, or SSBs, are composed of solid electrolytes, as opposed to the liquid electrolytes in lithium-ion batteries. With high energy and power density levels, SSBs have the potential to be an effective way to electrify the transportation sector.

However, the lack of an existing framework for constructing SSBs poses a barrier to their economic feasibility.

To overcome this problem, ORNL researchers developed SolidPAC, a traditional spreadsheet and graphical user interface-based tool for examining and developing SSB properties. The open source toolkit includes general design guidelines to predict cell-, module- and pack-level energy densities based on user-defined parameters for the battery system.

SolidPAC offers specific design rationales for building highly energy-dense SSBs and will help determine battery metrics needed for SSBs to become comparable to lithium-ion batteries.

Funding for this project was provided by DOE’s Laboratory Directed Research and Development program.

ORNL’s Ilias Belharouak led the development. ORNL’s Marm Dixit, Nitin Muralidharan, Ruhul Amin, Rachid Essehli and Mahalingam Balasubramanian also contributed to SolidPAC.

Ultraclean Condensing Gas Furnace, developed by ORNL.

Commercial and residential condensing natural gas furnaces contribute to climate change by releasing acidic water and harmful gas emissions, all capable of causing long-term harm to soil, water and air.

To mitigate damage from these pollutants, ORNL researchers developed the Ultraclean Condensing Gas Furnace, which utilizes monolithic acidic gas reduction, or AGR, as the catalyst to remove more than 99.9% of acidic gases and other emissions, such as carbon monoxide, hydrocarbons and methane, from furnaces.

This leads to not only neutral condensate that is highly environmentally friendly, but also ultraclean flue gas that meets future emissions regulations. Neutral condensate enables a simpler and less expensive furnace design, which yields a higher efficiency ultrahigh furnace and a reduction in installation costs.

AGR functions like a catalytic converter in a car, passing the exhaust over metals to reduce acidic gases and pollutant emissions that contribute to global climate change.

Ultraclean can be integrated into current furnace designs without altering manufacturing processes and applied to other gas-driven devices like gas boilers, commercial natural gas equipment, industrial furnaces and natural gas water heaters.

Funding for this project was provided by the DOE Office of Energy Efficiency and Renewable Energy’s Building Technologies Office.

ORNL’s Zhiming Gao led the development. Research contributors included ORNL’s Kyle Gluesenkamp, Kashif Nawaz, Anthony Gehl, Josh Pihl, Dino Sulejmanovic, Tim LaClair, Mingkan Zhang, Lingshi Wang, Van Baxter, Bo Shen, Xiaobing Liu, Jeff Munk and Jim Parks.

Flash-X, a Multiphysics Simulation Software, developed by Argonne National Laboratory, ORNL, Michigan State University, University of Chicago, University of Illinois at Urbana-Champaign and RIKEN Center for Computational Science, Japan.

Flash-X is a highly flexible software instrument that uses a combination of partial and ordinary differential and algebraic equations to simulate different types of physical phenomena, including astrophysics, computational fluid dynamics and cosmology.

The technology is highly accessible; Flash-X has a performance portability layer that is language agnostic, making it compatible with a variety of computer systems. The open-source software features components in an easily customizable plug-and-play mode for most scientific applications. The configuration of specific applications is divided into smaller portions so that each individual configuration tool remains relatively simple. Flash-X also publishes its auditing and quality control processes and features.

A previous version of the software, FLASH, was employed for a variety of scientific discovery purposes over the past decade but is no longer fully compatible with state-of-the-art computing systems and supercomputers, especially hybrid CPU-GPU systems like the Frontier and upcoming Aurora supercomputers at ORNL and ANL, respectively. FLASH was used as a tool to teach astrophysical concepts, and Flash-X could be employed for teaching purposes, as well.

Funding for this project was provided by the DOE Office of Science’s Advanced Scientific Computing Research program as part of the Exascale Computing Project, a joint effort of two DOE organizations, the Office of Science and the National Nuclear Security Administration.

Argonne’s Anshu Dubey led the development. Research contributors included ORNL’s Bronson Messer, J. Austin Harris, Thomas Papatheodore, Eirik Endeve and William Raphael Hix; Argonne’s Klaus Weide, Jared O’Neal, Akash Dhruv, Johann Rudi, Tom Klosterman, Rajeev Jain, Paul M. Rich and Katherine M. Riley; Michigan State University’s Sean M. Couch; RIKEN Center for Computational Science’s Mohammed Wahib; the University of Illinois’ Paul Ricker; the University of California Santa Cruz’s Dongwook Lee; Google’s Muralikrishnan Ganapathy; California Institute of Technology’s Michael Pajkos; the University of Tennessee’s Ran Chu; Lawrence Berkeley National Laboratory’s Christopher Steven Daley and Katie Antypas; Amazon’s Shravan Kumar Gopal; Nvidia’s John Bachan; and the University of Alabama’s Dean M. Townsley.

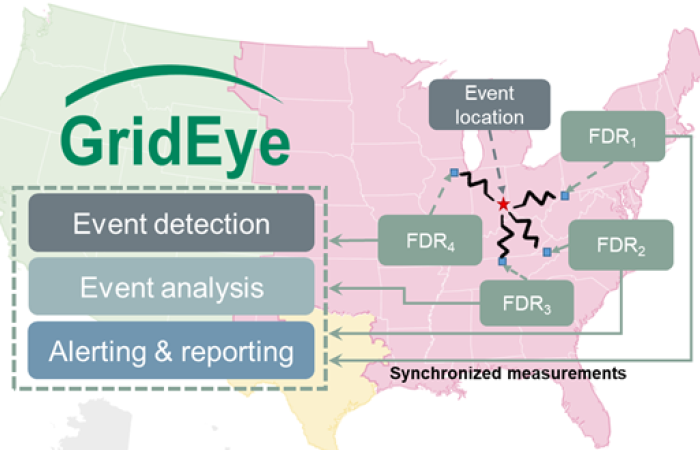

GridEye: A Wide-Area Power Grid Real-Time Situational Awareness System, developed by the University of Tennessee and ORNL.

As climate change causes frequent major weather events and power grids rely increasingly on renewable energy sources, the need for greater situational awareness and event monitoring continues to grow.

To quickly detect and provide information about major events across the North American power grid, researchers at UT and ORNL developed a monitoring system, GridEye.

GridEye uses more than 300 frequency disturbance recorders — monitors that can be installed anywhere with an 110V outlet, Ethernet and GPS access — to collect data on frequency variation across the grid. Sudden changes in frequency indicate an unusual event, such as an electric generator shutdown.

Within seconds, GridEye can detect anomalies within the system to pinpoint their locations and the size of the power loss. The technology then sends out alerts with email event analysis reports featuring incident details and location information to power companies, grid operators and other stakeholders, so affected parties can take the proper actions, such as ramp up additional power generation.

GridEye is the first and only monitoring solution for electric power grids across North America and allows power companies to see outside their own service areas.

Funding for this project was provided by DOE, the National Science Foundation, Dominion Energy, Tennessee Valley Authority, North American Electric Reliability Corporation and Electric Power Research Institute.

UT-ORNL Governor's Chair Yilu Liu and UT’s He Yin and Wenpeng Yu led the research. Contributors to GridEye’s development include ORNL’s Thomas J. King Jr. and Lingwei Zhan; UT’s Shutang You, Yi Zhao, Jiaojiao Dong, Yuru Wu, Zhihao Jiang, Xinlan Jia, Wei Qiu, Chengwen Zhang, Chang Chen, Chujie Zeng and Hongyu Li; Dominion Energy’s Matt Gardner; and Electric Power Research Institute’s Lin Zhu.

UT-Battelle manages ORNL for the Department of Energy’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit energy.gov/science. – Alexandra DeMarco