ORNL will team up with six of eight companies that are advancing designs and research and development for fusion power plants with the mission to achieve a pilot-scale demonstration of fusion within a decade.

ORNL will team up with six of eight companies that are advancing designs and research and development for fusion power plants with the mission to achieve a pilot-scale demonstration of fusion within a decade.

ORNL has entered a strategic research partnership with the United Kingdom Atomic Energy Authority, or UKAEA, to investigate how different types of materials behave under the influence of high-energy neutron sources.

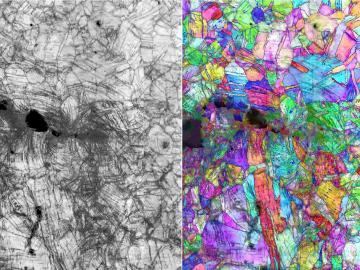

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

Three researchers at ORNL have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

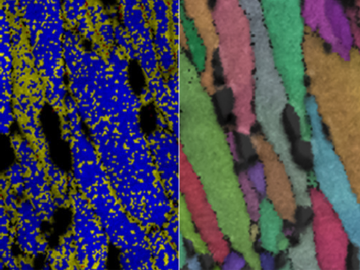

Scientists have measured the highest toughness ever recorded, of any material, while investigating a metallic alloy made of chromium, cobalt and nickel, or CrCoNi.

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

Muralidharan was recognized for “a highly prolific spirit of innovation in creating or facilitating outstanding inventions that have made a tangible impact on the quality of life, economic development and welfare of society.”

Ten scientists from the Department of Energy’s Oak Ridge National Laboratory are among the world’s most highly cited researchers, according to a bibliometric analysis conducted by the scientific publication analytics firm Clarivate.

ORNL's Larry Baylor and Andrew Lupini have been elected fellows of the American Physical Society.

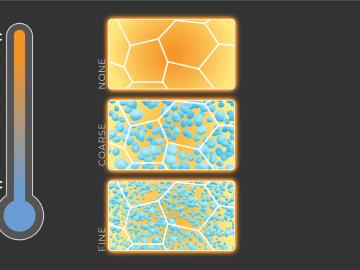

Scientists at ORNL and the University of Tennessee, Knoxville, have found a way to simultaneously increase the strength and ductility of an alloy by introducing tiny precipitates into its matrix and tuning their size and spacing.