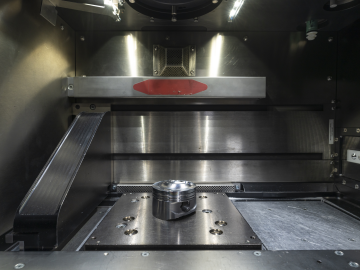

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

Using neutrons to see the additive manufacturing process at the atomic level, scientists have shown that they can measure strain in a material as it evolves and track how atoms move in response to stress.

ORNL has been selected to lead an Energy Earthshot Research Center, or EERC, focused on developing chemical processes that use sustainable methods instead of burning fossil fuels to radically reduce industrial greenhouse gas emissions to stem climate ch

Dean Pierce of ORNL and a research team led by ORNL’s Alex Plotkowski were honored by DOE’s Vehicle Technologies Office for development of novel high-performance alloys that can withstand extreme environments.

An advance in a topological insulator material — whose interior behaves like an electrical insulator but whose surface behaves like a conductor — could revolutionize the fields of next-generation electronics and quantum computing, according to scientist

A series of new classes at Pellissippi State Community College will offer students a new career path — and a national laboratory a pipeline of workers who have the skills needed for its own rapidly growing programs.

Alice Perrin is passionate about scientific research, but also beans — as in legumes.

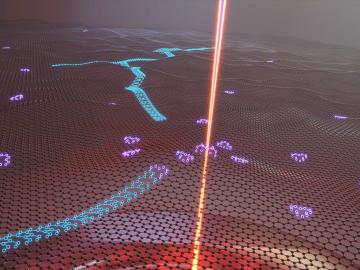

Oak Ridge National Laboratory researchers serendipitously discovered when they automated the beam of an electron microscope to precisely drill holes in the atomically thin lattice of graphene, the drilled holes closed up.

Laboratory Director Thomas Zacharia presented five Director’s Awards during Saturday night's annual Awards Night event hosted by UT-Battelle, which manages ORNL for the Department of Energy.

Researchers at the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2022 R&D 100 Awards, plus special recognition for a battery-related green technology product.

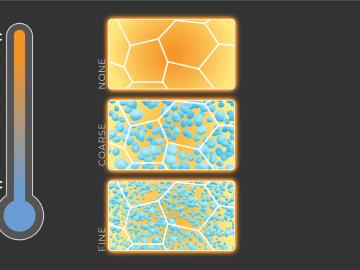

Scientists at ORNL and the University of Tennessee, Knoxville, have found a way to simultaneously increase the strength and ductility of an alloy by introducing tiny precipitates into its matrix and tuning their size and spacing.