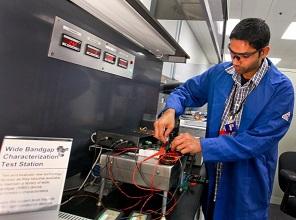

The Electrical and Electronics Systems Research Division’s (EESR’s) Power Electronics and Electric Machinery (PEEM) Group is putting its unique wide bandgap (WBG) evaluation facilities to work in benchmarking components used in devices such as inverters, converters, and onboard vehicle chargers.

PEEM’s WBG facility can autonomously evaluate any WBG device, in any package or in bare semiconductor form, for any power level. Results covering a variety of performance and efficiency metrics are available to research partners, academia, and industry through the PEEM website.

EESR’s Burak Ozpineci and Madhu Chinthavali have been studying silicon carbide, and more recently gallium nitride, devices for more than a dozen years. Their evaluations initially were done manually using a silicon carbide diode they acquired in 2001 from Germany—the technology was not yet available in the United States. “But it became very tedious. We needed a better way,” Ozpineci said. “So we devised an automated system.

“It’s like plug-and-play or Legos. It’s already built,” he continued, explaining that a researcher can set the system up based on the voltage and current levels a particular device requires, then activate software to control some characteristics automatically.

The system uses precise, proprietary software that PEEM developed. The software features a unique fundamental device calculator and requires only the push of a button to run all day and evaluate loss characteristics during operation.

WBG technology enables devices to perform more efficiently at a greater range of temperatures than conventional semiconductor materials. Advantages of WBG devices include higher inherent reliability, overall efficiency, frequency operation, temperature capability and tolerance, and power density, as well as lighter weight (enabling systems that are more compact).

Although manufacturers typically run their own device tests under optimal conditions, “We look at how these devices will be operated where the conditions are not necessarily optimal. We want to see the ugly, too,” Ozpineci said.

Chinthavali noted the benefit for manufacturers. “Sometimes we come across data or results they don’t have, and they appreciate that feedback,” he said.

“We have the latest device in the world in our lab today, which is very unique,” he continued. “You can walk in with a bare diode or a switch of any wide bandgap or existing semiconductor technology, and we can give you the spec sheet for it, including the rating on the device, how it works, and what’s needed for it to be scaled.”

Probably the most significant interest in this research comes from vehicle manufacturers; some have asked to license the setup or to have ORNL set up a system for them. However, the technology has a wide range of applications beyond transportation, such as solar and renewables. The group also is trying to expand into high voltage, which may lead to grid applications. --Wendy Hames