Filter News

Area of Research

- (-) Energy Science (65)

- (-) National Security (8)

- (-) Neutron Science (8)

- Advanced Manufacturing (12)

- Biological Systems (1)

- Biology and Environment (6)

- Building Technologies (1)

- Computational Engineering (1)

- Computer Science (6)

- Fusion and Fission (1)

- Fusion Energy (1)

- Materials (28)

- Materials for Computing (2)

- Nuclear Science and Technology (6)

- Quantum information Science (3)

- Supercomputing (25)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (34)

- (-) Artificial Intelligence (7)

- (-) Bioenergy (21)

- (-) Cybersecurity (7)

- (-) Grid (12)

- (-) Polymers (6)

- Advanced Reactors (3)

- Big Data (6)

- Biology (2)

- Biomedical (14)

- Biotechnology (2)

- Chemical Sciences (2)

- Clean Water (6)

- Composites (4)

- Computer Science (27)

- Coronavirus (15)

- Critical Materials (3)

- Energy Storage (23)

- Environment (35)

- Exascale Computing (1)

- High-Performance Computing (1)

- Isotopes (1)

- Machine Learning (8)

- Materials (2)

- Materials Science (24)

- Mathematics (2)

- Mercury (2)

- Microscopy (5)

- Molten Salt (1)

- Nanotechnology (12)

- National Security (2)

- Neutron Science (56)

- Nuclear Energy (7)

- Physics (6)

- Quantum Science (5)

- Security (7)

- Space Exploration (2)

- Summit (8)

- Transportation (28)

Media Contacts

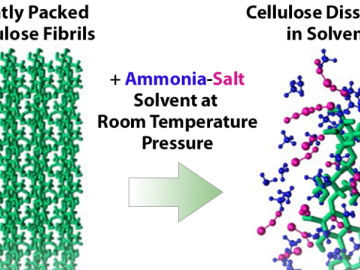

Researchers have developed a new process that could make it much cheaper to produce biofuels such as ethanol from plant waste and reduce reliance on fossil fuels.

To better determine the potential energy cost savings among connected homes, researchers at Oak Ridge National Laboratory developed a computer simulation to more accurately compare energy use on similar weather days.

Illustration of the optimized zeolite catalyst, or NbAlS-1, which enables a highly efficient chemical reaction to create butene, a renewable source of energy, without expending high amounts of energy for the conversion. Credit: Jill Hemman, Oak Ridge National Laboratory/U.S. Dept. of Energy

A technology developed at the ORNL and scaled up by Vertimass LLC to convert ethanol into fuels suitable for aviation, shipping and other heavy-duty applications can be price-competitive with conventional fuels

Students often participate in internships and receive formal training in their chosen career fields during college, but some pursue professional development opportunities even earlier.

Oak Ridge National Laboratory will give college students the chance to practice cybersecurity skills in a real-world setting as a host of the Department of Energy’s fifth collegiate CyberForce Competition on Nov. 16. The event brings together student teams from across the country to compete at 10 of DOE’s national laboratories.

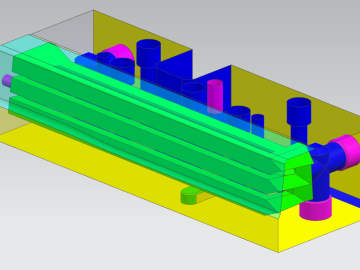

Researchers demonstrated that an additively manufactured hot stamping die can withstand up to 25,000 usage cycles, proving that this technique is a viable solution for production.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

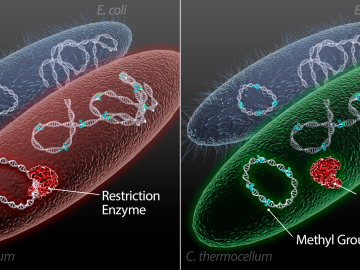

Scientists at the US Department of Energy’s Oak Ridge National Laboratory have demonstrated a method to insert genes into a variety of microorganisms that previously would not accept foreign DNA, with the goal of creating custom microbes to break down plants for bioenergy.