Filter News

Area of Research

- Advanced Manufacturing (10)

- Biology and Environment (2)

- Computer Science (1)

- Electricity and Smart Grid (1)

- Energy Science (34)

- Fusion Energy (1)

- Isotopes (5)

- Materials (6)

- Materials for Computing (1)

- National Security (3)

- Neutron Science (4)

- Nuclear Science and Technology (2)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (2)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (25)

- (-) Biomedical (3)

- (-) Cybersecurity (4)

- (-) Energy Storage (12)

- (-) Grid (10)

- (-) Isotopes (5)

- (-) Physics (4)

- (-) Space Exploration (6)

- Advanced Reactors (7)

- Artificial Intelligence (8)

- Big Data (10)

- Bioenergy (8)

- Biology (12)

- Biotechnology (3)

- Buildings (7)

- Chemical Sciences (1)

- Clean Water (9)

- Composites (5)

- Computer Science (27)

- Coronavirus (4)

- Critical Materials (2)

- Environment (33)

- Exascale Computing (1)

- Fusion (6)

- High-Performance Computing (9)

- ITER (3)

- Machine Learning (3)

- Materials (17)

- Materials Science (20)

- Mathematics (1)

- Mercury (2)

- Microscopy (6)

- Molten Salt (1)

- Nanotechnology (5)

- National Security (2)

- Neutron Science (14)

- Nuclear Energy (13)

- Polymers (3)

- Quantum Computing (1)

- Quantum Science (7)

- Security (1)

- Statistics (1)

- Summit (2)

- Transportation (23)

Media Contacts

Oak Ridge National Laboratory researchers have demonstrated that a new class of superalloys made of cobalt and nickel remains crack-free and defect-resistant in extreme heat, making them conducive for use in metal-based 3D printing applications.

A better way of welding targets for Oak Ridge National Laboratory’s plutonium-238 production has sped up the process and improved consistency and efficiency. This advancement will ultimately benefit the lab’s goal to make enough Pu-238 – the isotope that powers NASA’s deep space missions – to yield 1.5 kilograms of plutonium oxide annually by 2026.

Collaborators at Oak Ridge National Laboratory and the University of Tennessee Health Science Center are developing a breath-sampling whistle that could make COVID-19 screening easy to do at home.

A new Department of Energy report produced by Oak Ridge National Laboratory details national and international trends in hydropower, including the role waterpower plays in enhancing the flexibility and resilience of the power grid.

Growing up in the heart of the American automobile industry near Detroit, Oak Ridge National Laboratory materials scientist Mike Kirka was no stranger to manufacturing.

Algorithms developed at Oak Ridge National Laboratory can greatly enhance X-ray computed tomography images of 3D-printed metal parts, resulting in more accurate, faster scans.

Researchers at Oak Ridge National Laboratory demonstrated that an additively manufactured polymer layer, when applied to carbon fiber reinforced plastic, or CFRP, can serve as an effective protector against aircraft lightning strikes.

If humankind reaches Mars this century, an Oak Ridge National Laboratory-developed experiment testing advanced materials for spacecraft may play a key role.

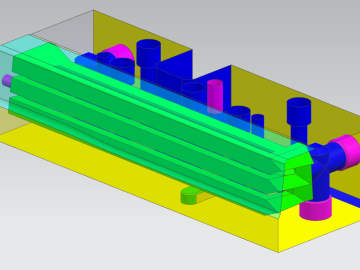

Researchers demonstrated that an additively manufactured hot stamping die can withstand up to 25,000 usage cycles, proving that this technique is a viable solution for production.

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.