Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (12)

- (-) Bioenergy (14)

- (-) Biomedical (5)

- (-) Grid (11)

- (-) Microscopy (4)

- (-) Security (1)

- (-) Transportation (7)

- Advanced Reactors (1)

- Artificial Intelligence (18)

- Big Data (10)

- Biology (18)

- Biotechnology (2)

- Buildings (6)

- Chemical Sciences (10)

- Clean Water (7)

- Composites (2)

- Computer Science (26)

- Coronavirus (1)

- Critical Materials (1)

- Cybersecurity (6)

- Emergency (1)

- Energy Storage (11)

- Environment (38)

- Exascale Computing (13)

- Fossil Energy (2)

- Frontier (13)

- Fusion (8)

- High-Performance Computing (18)

- Hydropower (2)

- Isotopes (7)

- Machine Learning (11)

- Materials (21)

- Materials Science (10)

- Mathematics (2)

- Mercury (2)

- Microelectronics (2)

- Nanotechnology (5)

- National Security (15)

- Neutron Science (27)

- Nuclear Energy (19)

- Partnerships (6)

- Physics (12)

- Polymers (2)

- Quantum Computing (6)

- Quantum Science (5)

- Simulation (19)

- Software (1)

- Space Exploration (5)

- Summit (11)

Media Contacts

The Center for Bioenergy Innovation has been renewed by the Department of Energy as one of four bioenergy research centers across the nation to advance robust, economical production of plant-based fuels and chemicals.

Scientists at ORNL have confirmed that bacteria-killing viruses called bacteriophages deploy a sneaky tactic when targeting their hosts: They use a standard genetic code when invading bacteria, then switch to an alternate code at later stages of

Joanna Tannous has found the perfect organism to study to satisfy her deeply curious nature, her skills in biochemistry and genetics, and a drive to create solutions for a better world. The organism is a poorly understood life form that greatly influences its environment and is unique enough to deserve its own biological kingdom: fungi.

Illustration of the optimized zeolite catalyst, or NbAlS-1, which enables a highly efficient chemical reaction to create butene, a renewable source of energy, without expending high amounts of energy for the conversion. Credit: Jill Hemman, Oak Ridge National Laboratory/U.S. Dept. of Energy

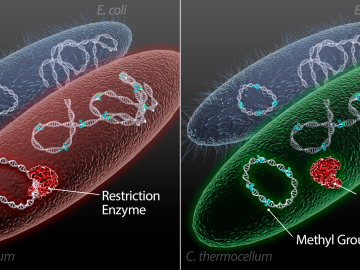

Scientists at the US Department of Energy’s Oak Ridge National Laboratory have demonstrated a method to insert genes into a variety of microorganisms that previously would not accept foreign DNA, with the goal of creating custom microbes to break down plants for bioenergy.

A modern, healthy transportation system is vital to the nation’s economic security and the American standard of living. The U.S. Department of Energy’s Oak Ridge National Laboratory (ORNL) is engaged in a broad portfolio of scientific research for improved mobility

Isabelle Snyder calls faults as she sees them, whether it’s modeling operations for the nation’s power grid or officiating at the US Open Tennis Championships.

Early career scientist Stephanie Galanie has applied her expertise in synthetic biology to a number of challenges in academia and private industry. She’s now bringing her skills in high-throughput bio- and analytical chemistry to accelerate research on feedstock crops as a Liane B. Russell Fellow at Oak Ridge National Laboratory.

In Hong Wang’s world, nothing is beyond control. Before joining Oak Ridge National Laboratory as a senior distinguished researcher in transportation systems, he spent more than three decades studying the control of complex industrial systems in the United Kingdom.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.