Filter News

Area of Research

- (-) Fusion Energy (13)

- (-) Materials (52)

- (-) National Security (11)

- Advanced Manufacturing (14)

- Biological Systems (1)

- Biology and Environment (17)

- Building Technologies (1)

- Computational Biology (2)

- Computer Science (2)

- Electricity and Smart Grid (2)

- Energy Science (84)

- Fusion and Fission (30)

- Isotopes (9)

- Materials for Computing (10)

- Neutron Science (24)

- Nuclear Science and Technology (29)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (28)

- Transportation Systems (1)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (11)

- (-) Biomedical (5)

- (-) Fusion (11)

- (-) Grid (7)

- (-) Materials Science (36)

- (-) Molten Salt (1)

- (-) Nuclear Energy (20)

- (-) Space Exploration (2)

- Advanced Reactors (7)

- Artificial Intelligence (10)

- Big Data (7)

- Bioenergy (5)

- Biology (3)

- Biotechnology (1)

- Buildings (3)

- Chemical Sciences (11)

- Clean Water (3)

- Composites (6)

- Computer Science (21)

- Coronavirus (4)

- Critical Materials (5)

- Cybersecurity (9)

- Energy Storage (14)

- Environment (11)

- Exascale Computing (1)

- Frontier (1)

- High-Performance Computing (4)

- Isotopes (8)

- Machine Learning (9)

- Materials (32)

- Mathematics (1)

- Microscopy (12)

- Nanotechnology (16)

- National Security (23)

- Neutron Science (14)

- Partnerships (4)

- Physics (12)

- Polymers (10)

- Quantum Computing (2)

- Quantum Science (2)

- Security (6)

- Simulation (1)

- Summit (4)

- Transportation (11)

Media Contacts

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

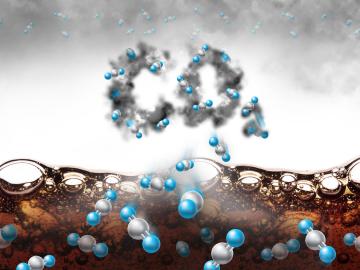

Oak Ridge National Laboratory has teamed with Cornell College and the University of Tennessee to study ways to repurpose waste soft drinks for carbon capture that could help cut carbon dioxide emissions.

A team of researchers at Oak Ridge National Laboratory have demonstrated that designed synthetic polymers can serve as a high-performance binding material for next-generation lithium-ion batteries.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

Scientists have discovered a way to alter heat transport in thermoelectric materials, a finding that may ultimately improve energy efficiency as the materials

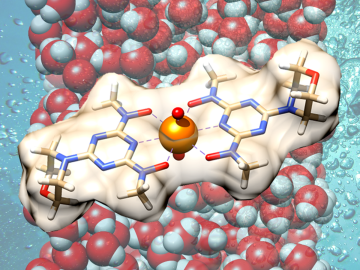

Scientists have demonstrated a new bio-inspired material for an eco-friendly and cost-effective approach to recovering uranium from seawater.

Researchers at the Department of Energy’s Oak Ridge National Laboratory, Pacific Northwest National Laboratory and Washington State University teamed up to investigate the complex dynamics of low-water liquids that challenge nuclear waste processing at federal cleanup sites.

Scientists at the Department of Energy’s Oak Ridge National Laboratory are working to understand both the complex nature of uranium and the various oxide forms it can take during processing steps that might occur throughout the nuclear fuel cycle.

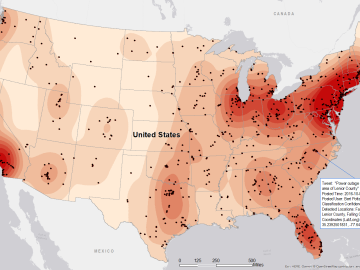

Gleaning valuable data from social platforms such as Twitter—particularly to map out critical location information during emergencies— has become more effective and efficient thanks to Oak Ridge National Laboratory.

Scientists have tested a novel heat-shielding graphite foam, originally created at Oak Ridge National Laboratory, at Germany’s Wendelstein 7-X stellarator with promising results for use in plasma-facing components of fusion reactors.