Filter News

Area of Research

- Advanced Manufacturing (1)

- Biology and Environment (13)

- Computer Science (1)

- Energy Science (19)

- Fusion and Fission (3)

- Isotope Development and Production (1)

- Isotopes (16)

- Materials (26)

- Materials for Computing (4)

- National Security (19)

- Neutron Science (4)

- Nuclear Science and Technology (4)

- Quantum information Science (1)

- Sensors and Controls (1)

- Supercomputing (14)

News Type

News Topics

- (-) Composites (17)

- (-) Cybersecurity (24)

- (-) Isotopes (37)

- (-) Microscopy (31)

- (-) Security (19)

- (-) Space Exploration (3)

- 3-D Printing/Advanced Manufacturing (73)

- Advanced Reactors (16)

- Artificial Intelligence (55)

- Big Data (29)

- Bioenergy (52)

- Biology (57)

- Biomedical (34)

- Biotechnology (19)

- Buildings (32)

- Chemical Sciences (52)

- Clean Water (9)

- Computer Science (93)

- Coronavirus (23)

- Critical Materials (13)

- Education (3)

- Element Discovery (1)

- Emergency (1)

- Energy Storage (61)

- Environment (91)

- Exascale Computing (26)

- Fossil Energy (1)

- Frontier (27)

- Fusion (29)

- Grid (28)

- High-Performance Computing (57)

- Hydropower (2)

- Irradiation (1)

- ITER (4)

- Machine Learning (27)

- Materials (80)

- Materials Science (75)

- Mathematics (5)

- Mercury (6)

- Microelectronics (1)

- Molten Salt (3)

- Nanotechnology (38)

- National Security (40)

- Neutron Science (71)

- Nuclear Energy (52)

- Partnerships (36)

- Physics (43)

- Polymers (19)

- Quantum Computing (17)

- Quantum Science (40)

- Simulation (23)

- Software (1)

- Statistics (1)

- Summit (26)

- Transportation (49)

Media Contacts

Researchers at ORNL have developed an innovative new technique using carbon nanofibers to enhance binding in carbon fiber and other fiber-reinforced polymer composites – an advance likely to improve structural materials for automobiles, airplanes and other applications that require lightweight and strong materials.

Robert “Bob” Hettich, an ORNL Corporate Fellow, is a pioneer in using mass spectrometry to uncover how microbes interact within complex environments and influence larger systems like plants and humans. A founder of the field of metaproteomics, he leads research that supports bioenergy, environmental resilience and health through advanced protein analysis.

Scientists at ORNL have developed a method that can track chemical changes in molten salt in real time — helping to pave the way for the deployment of molten salt reactors for energy production.

Neus Domingo Marimon, leader of the Functional Atomic Force Microscopy group at the Center for Nanophase Materials Sciences of ORNL, has been elevated to senior member of the Institute of Electrical and Electronics Engineers.

P&G is using simulations on the ORNL Summit supercomputer to study how surfactants in cleaners cause eye irritation. By modeling the corneal epithelium, P&G aims to develop safer, concentrated cleaning products that meet performance and safety standards while supporting sustainability goals.

Ryan Culler is the program manager at Oak Ridge National Laboratory, where he oversees the production of actinium-225, a promising treatment for cancer. Driven by a personal connection to cancer through his late brother, Culler is dedicated to advancing medical isotopes to help improve cancer care.

Chad Parish, a senior researcher at ORNL, studies materials at the atomic level to improve nuclear reactors. His work focuses on fusion and fission energy, using microscopy and collaborating with experts to advance materials for extreme environments.

From during his early years at NASA to his current role a researcher and group leader, Peter Fuhr has pushed the boundaries of optical and sensor technology. Fuhr’s path is marked by wacky creativity that can’t confine itself to challenges in a single field. No idea is too far out to try out — and so many of them work that Fuhr has a host of inventions and start-ups under his belt.

The Department of Energy has awarded an $88.8 million contract to Hensel Phelps for the construction of a facility to enrich stable isotopes at Oak Ridge National Laboratory.

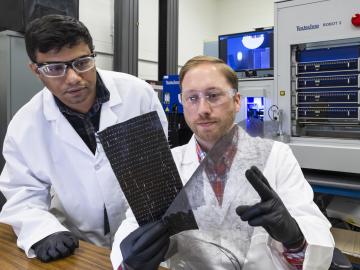

ORNL researchers were honored with a prestigious ACE Award for Composites Excellence by the American Composites Manufacturers Association. The team won the “innovation in green composites design” prize for creating a fully recyclable, lightweight wind turbine blade tip that incorporates low-cost carbon fiber and conductive coating for enhanced protection against lightning strikes.