Filter News

Area of Research

- Advanced Manufacturing (3)

- Biology and Environment (20)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (2)

- Energy Science (91)

- Energy Sciences (1)

- Fusion and Fission (5)

- Fusion Energy (1)

- Isotope Development and Production (1)

- Isotopes (11)

- Materials (68)

- Materials for Computing (11)

- National Security (6)

- Neutron Science (25)

- Nuclear Science and Technology (7)

- Quantum information Science (1)

- Supercomputing (37)

- Transportation Systems (2)

News Type

News Topics

- (-) Biomedical (28)

- (-) Composites (23)

- (-) Energy Storage (75)

- (-) Frontier (17)

- (-) Hydropower (6)

- (-) Isotopes (25)

- (-) Microscopy (28)

- (-) Physics (30)

- (-) Space Exploration (13)

- (-) Transportation (62)

- 3-D Printing/Advanced Manufacturing (82)

- Advanced Reactors (25)

- Artificial Intelligence (51)

- Big Data (25)

- Bioenergy (42)

- Biology (47)

- Biotechnology (14)

- Buildings (36)

- Chemical Sciences (48)

- Clean Water (16)

- Computer Science (105)

- Coronavirus (28)

- Critical Materials (23)

- Cybersecurity (20)

- Education (3)

- Element Discovery (1)

- Emergency (1)

- Environment (86)

- Exascale Computing (14)

- Fossil Energy (2)

- Fusion (26)

- Grid (38)

- High-Performance Computing (44)

- Irradiation (2)

- ITER (5)

- Machine Learning (27)

- Materials (96)

- Materials Science (90)

- Mathematics (3)

- Mercury (5)

- Microelectronics (1)

- Molten Salt (8)

- Nanotechnology (41)

- National Security (21)

- Neutron Science (81)

- Nuclear Energy (47)

- Partnerships (33)

- Polymers (23)

- Quantum Computing (18)

- Quantum Science (42)

- Security (13)

- Simulation (19)

- Statistics (2)

- Summit (30)

Media Contacts

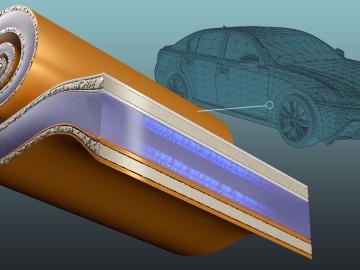

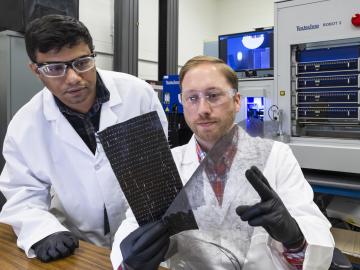

Strengthening the competitiveness of the U.S. transportation industry depends on developing domestic EV batteries that combine rapid charging with long-range performance — two goals that often conflict. Researchers at ORNL have addressed this challenge by redesigning a key battery component, enabling fast, 10-minute charging while improving energy density and reducing reliance on copper.

Researchers at ORNL have developed an innovative new technique using carbon nanofibers to enhance binding in carbon fiber and other fiber-reinforced polymer composites – an advance likely to improve structural materials for automobiles, airplanes and other applications that require lightweight and strong materials.

Analyzing massive datasets from nuclear physics experiments can take hours or days to process, but researchers are working to radically reduce that time to mere seconds using special software being developed at the Department of Energy’s Lawrence Berkeley and Oak Ridge national laboratories.

Scientists at ORNL have developed a vacuum-assisted extrusion method that reduces internal porosity by up to 75% in large-scale 3D-printed polymer parts. This new technique addresses the critical issue of porosity in large-scale prints but also paves the way for stronger composites.

Scientists at ORNL have developed a method that can track chemical changes in molten salt in real time — helping to pave the way for the deployment of molten salt reactors for energy production.

Using the Frontier supercomputer at ORNL, researchers have developed a new technique that predicts nuclear properties in record detail. The study revealed how the structure of a nucleus relates to the force that holds it together. This understanding could advance efforts in quantum physics and across a variety of sectors, from to energy production to national security.

P&G is using simulations on the ORNL Summit supercomputer to study how surfactants in cleaners cause eye irritation. By modeling the corneal epithelium, P&G aims to develop safer, concentrated cleaning products that meet performance and safety standards while supporting sustainability goals.

The Department of Energy has awarded an $88.8 million contract to Hensel Phelps for the construction of a facility to enrich stable isotopes at Oak Ridge National Laboratory.

Scientists at ORNL are studying the failure mechanisms of a new solid electrolyte battery to enhance long-term storage for renewable energy, aiming to make wind and solar power more reliable for the electric grid.

Oak Ridge National Laboratory researchers are using a new bioderived material to 3D print custom roosting structures for endangered bats.