Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (58)

- Building Technologies (2)

- Computational Biology (1)

- Computational Engineering (3)

- Computer Science (15)

- Electricity and Smart Grid (3)

- Energy Science (154)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (1)

- Fusion and Fission (8)

- Fusion Energy (3)

- Isotopes (26)

- Materials (94)

- Materials for Computing (17)

- Mathematics (1)

- National Security (58)

- Neutron Science (130)

- Nuclear Science and Technology (15)

- Quantum information Science (9)

- Sensors and Controls (1)

- Supercomputing (129)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (147)

- (-) Big Data (79)

- (-) Clean Water (33)

- (-) Computer Science (226)

- (-) Fossil Energy (8)

- (-) Grid (74)

- (-) Isotopes (62)

- (-) Machine Learning (68)

- (-) National Security (86)

- (-) Neutron Science (171)

- (-) Quantum Science (93)

- Advanced Reactors (40)

- Artificial Intelligence (131)

- Bioenergy (112)

- Biology (128)

- Biomedical (73)

- Biotechnology (39)

- Buildings (74)

- Chemical Sciences (86)

- Composites (35)

- Coronavirus (48)

- Critical Materials (29)

- Cybersecurity (35)

- Education (5)

- Element Discovery (1)

- Emergency (4)

- Energy Storage (114)

- Environment (218)

- Exascale Computing (67)

- Frontier (64)

- Fusion (67)

- High-Performance Computing (130)

- Hydropower (12)

- Irradiation (3)

- ITER (9)

- Materials (157)

- Materials Science (158)

- Mathematics (12)

- Mercury (12)

- Microelectronics (4)

- Microscopy (56)

- Molten Salt (10)

- Nanotechnology (64)

- Nuclear Energy (122)

- Partnerships (68)

- Physics (69)

- Polymers (35)

- Quantum Computing (53)

- Security (31)

- Simulation (65)

- Software (1)

- Space Exploration (26)

- Statistics (4)

- Summit (71)

- Transportation (103)

Media Contacts

ORNL and JuggerBot 3D, an industrial 3D printer equipment manufacturer, have launched their second research and development collaboration through the Manufacturing Demonstration Facility Technical Collaboration Program.

From decoding plant genomes to modeling microbial behavior, computational biologist Priya Ranjan builds computational tools that turn extensive biological datasets into real-world insights. These tools transform the way scientists ask and answer complex biological questions that advance biotechnology breakthroughs and support cultivation of better crops for energy and food security.

Scientists have developed a new machine learning approach that accurately predicted critical and difficult-to-compute properties of molten salts, materials with diverse nuclear energy applications.

Stronger than steel and lighter than aluminum, carbon fiber is a staple in aerospace and high-performance vehicles — and now, scientists at ORNL have found a way to make it even stronger.

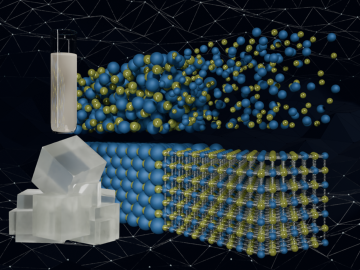

Using the now-decommissioned Summit supercomputer, researchers at ORNL ran the largest and most accurate molecular dynamics simulations yet of the interface between water and air during a chemical reaction. The simulations have uncovered how water controls such chemical reactions by dynamically coupling with the molecules involved in the process.

Members of the Quantum Science Center, or QSC, gathered at an all-hands meeting in Baton Rouge, Louisiana, in mid-May to reflect on the remarkable accomplishments from the past five years and to prepare for what members hope to be the next five years of the center.

Van Graves, an engineering manager at ORNL, is celebrating 40 years of dedicated service leading a diverse range of prominent engineering projects at ORNL and internationally.

ORNL’s Biological Monitoring and Abatement Program, or BMAP, is marking 40 years of helping steward the DOE’s 33,476 acres of land on which some of the nation’s most powerful science and technology missions are carried out.

Using the Frontier supercomputer, a team of researchers from the Massachusetts Institute of Technology conducted large-scale calculations to chart the isospin density of a neutron star across a range of conditions. Their work provides new insights into how pressure and density interact within neutron stars, offering important predictions about their inner workings.

Recent advancements at ORNL show that 3D-printed metal molds offer a faster, more cost-effective and flexible approach to producing large composite components for mass-produced vehicles than traditional tooling methods.