Filter News

Area of Research

- Advanced Manufacturing (22)

- Biology and Environment (36)

- Building Technologies (1)

- Computational Biology (1)

- Computational Engineering (2)

- Computer Science (4)

- Energy Science (92)

- Fusion and Fission (4)

- Fusion Energy (2)

- Materials (49)

- Materials for Computing (9)

- National Security (9)

- Neutron Science (14)

- Nuclear Science and Technology (4)

- Quantum information Science (2)

- Supercomputing (67)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (147)

- (-) Big Data (79)

- (-) Microscopy (56)

- (-) Summit (71)

- Advanced Reactors (40)

- Artificial Intelligence (131)

- Bioenergy (112)

- Biology (128)

- Biomedical (73)

- Biotechnology (39)

- Buildings (74)

- Chemical Sciences (86)

- Clean Water (33)

- Composites (35)

- Computer Science (226)

- Coronavirus (48)

- Critical Materials (29)

- Cybersecurity (35)

- Education (5)

- Element Discovery (1)

- Emergency (4)

- Energy Storage (114)

- Environment (218)

- Exascale Computing (67)

- Fossil Energy (8)

- Frontier (64)

- Fusion (66)

- Grid (74)

- High-Performance Computing (130)

- Hydropower (12)

- Irradiation (3)

- Isotopes (62)

- ITER (9)

- Machine Learning (68)

- Materials (157)

- Materials Science (158)

- Mathematics (12)

- Mercury (12)

- Microelectronics (4)

- Molten Salt (10)

- Nanotechnology (64)

- National Security (86)

- Neutron Science (171)

- Nuclear Energy (122)

- Partnerships (68)

- Physics (69)

- Polymers (35)

- Quantum Computing (53)

- Quantum Science (93)

- Security (31)

- Simulation (65)

- Software (1)

- Space Exploration (26)

- Statistics (4)

- Transportation (103)

Media Contacts

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

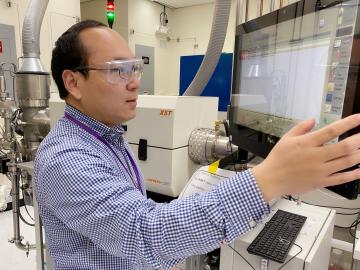

Scientists at ORNL and the University of Nebraska have developed an easier way to generate electrons for nanoscale imaging and sensing, providing a useful new tool for material science, bioimaging and fundamental quantum research.

Researchers at ORNL used quantum optics to advance state-of-the-art microscopy and illuminate a path to detecting material properties with greater sensitivity than is possible with traditional tools.

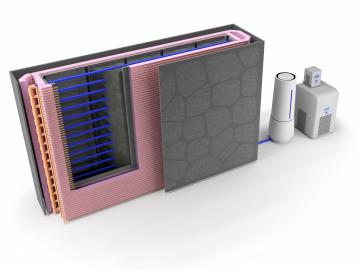

Oak Ridge National Laboratory researchers used additive manufacturing to build a first-of-its kind smart wall called EMPOWER.

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

Oak Ridge National Laboratory researchers have designed and additively manufactured a first-of-its-kind aluminum device that enhances the capture of carbon dioxide emitted from fossil fuel plants and other industrial processes.

The Society of Manufacturing Engineers, known as SME, has named William Peter, director of Oak Ridge National Laboratory’s Manufacturing Demonstration Facility in the Energy and Environmental Sciences Directorate, among its 2020 College of SME Fellows.

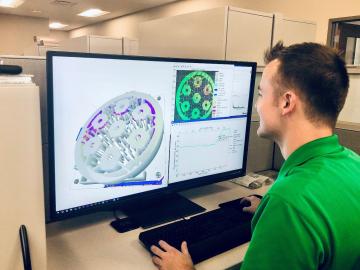

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

ORNL has licensed two additive manufacturing-related technologies that aim to streamline and ramp up production processes to Knoxville-based Magnum Venus Products, Inc., a global manufacturer of fluid movement and product solutions for industrial

A team led by Dan Jacobson of Oak Ridge National Laboratory used the Summit supercomputer at ORNL to analyze genes from cells in the lung fluid of nine COVID-19 patients compared with 40 control patients.