Filter News

Area of Research

- Advanced Manufacturing (7)

- Biology and Environment (57)

- Biology and Soft Matter (1)

- Computational Engineering (2)

- Computer Science (7)

- Electricity and Smart Grid (1)

- Energy Science (73)

- Functional Materials for Energy (2)

- Fusion and Fission (7)

- Fusion Energy (2)

- Isotope Development and Production (1)

- Isotopes (27)

- Materials (99)

- Materials Characterization (2)

- Materials for Computing (14)

- Materials Under Extremes (1)

- Mathematics (1)

- National Security (31)

- Neutron Science (26)

- Nuclear Science and Technology (9)

- Quantum information Science (9)

- Supercomputing (101)

News Topics

- (-) Big Data (79)

- (-) Cybersecurity (35)

- (-) Frontier (64)

- (-) Isotopes (62)

- (-) Materials (157)

- (-) Partnerships (68)

- (-) Quantum Science (93)

- (-) Space Exploration (26)

- 3-D Printing/Advanced Manufacturing (147)

- Advanced Reactors (40)

- Artificial Intelligence (131)

- Bioenergy (112)

- Biology (128)

- Biomedical (73)

- Biotechnology (39)

- Buildings (74)

- Chemical Sciences (86)

- Clean Water (33)

- Composites (35)

- Computer Science (226)

- Coronavirus (48)

- Critical Materials (29)

- Education (5)

- Element Discovery (1)

- Emergency (4)

- Energy Storage (114)

- Environment (218)

- Exascale Computing (67)

- Fossil Energy (8)

- Fusion (67)

- Grid (74)

- High-Performance Computing (130)

- Hydropower (12)

- Irradiation (3)

- ITER (9)

- Machine Learning (68)

- Materials Science (158)

- Mathematics (12)

- Mercury (12)

- Microelectronics (4)

- Microscopy (56)

- Molten Salt (10)

- Nanotechnology (64)

- National Security (86)

- Neutron Science (171)

- Nuclear Energy (122)

- Physics (69)

- Polymers (35)

- Quantum Computing (53)

- Security (31)

- Simulation (65)

- Software (1)

- Statistics (4)

- Summit (71)

- Transportation (103)

Media Contacts

As a computer engineer at Oak Ridge National Laboratory, Gina Accawi has long been the quiet and steady force behind some of the Department of Energy’s most widely used online tools and applications.

Deborah Frincke, one of the nation’s preeminent computer scientists and cybersecurity experts, serves as associate laboratory director of ORNL’s National Security Science Directorate. Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

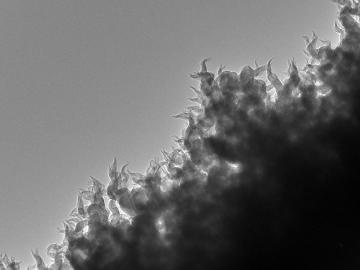

Sergei Kalinin, a scientist and inventor at the Department of Energy’s Oak Ridge National Laboratory, has been elected a fellow of the Microscopy Society of America professional society.

For years Brenda Smith found fulfillment working with nuclear batteries, a topic she’s been researching as a chemist at Oak Ridge National Laboratory.

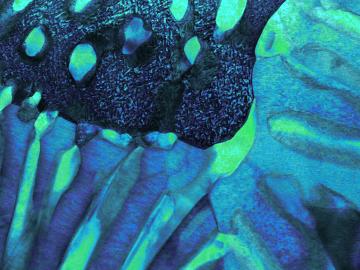

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a

Through a consortium of Department of Energy national laboratories, ORNL scientists are applying their expertise to provide solutions that enable the commercialization of emission-free hydrogen fuel cell technology for heavy-duty

The U.S. Department of Energy’s Innovative and Novel Computational Impact on Theory and Experiment, or INCITE, program is seeking proposals for high-impact, computationally intensive research campaigns in a broad array of science, engineering and computer science domains.

Oak Ridge National Laboratory scientists proved molybdenum titanium carbide, a refractory metal alloy that can withstand extreme temperature environments, can also be crack free and dense when produced with electron beam powder bed fusion.

In a new twist to an existing award-winning ORNL technology, researchers have developed an electrocatalyst that enables water and carbon dioxide to be split and the atoms recombined to form higher weight hydrocarbons for gasoline, diesel and jet fuel.

A team of researchers at Oak Ridge National Laboratory and the University of Tennessee have developed a concrete mix that demonstrated high early strength within six hours of mixing, potentially doubling the production capacity for the precast industry.