Filter News

Area of Research

- Advanced Manufacturing (6)

- Biology and Environment (12)

- Clean Energy (42)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (2)

- Fusion Energy (1)

- Isotopes (4)

- Materials (82)

- Materials Characterization (2)

- Materials for Computing (10)

- Materials Under Extremes (1)

- National Security (2)

- Neutron Science (14)

- Supercomputing (18)

News Topics

- (-) Critical Materials (29)

- (-) Emergency (2)

- (-) Materials (148)

- 3-D Printing/Advanced Manufacturing (128)

- Advanced Reactors (34)

- Artificial Intelligence (101)

- Big Data (62)

- Bioenergy (92)

- Biology (101)

- Biomedical (61)

- Biotechnology (24)

- Buildings (67)

- Chemical Sciences (73)

- Clean Water (31)

- Climate Change (106)

- Composites (30)

- Computer Science (198)

- Coronavirus (46)

- Cybersecurity (35)

- Decarbonization (85)

- Education (5)

- Element Discovery (1)

- Energy Storage (112)

- Environment (201)

- Exascale Computing (43)

- Fossil Energy (6)

- Frontier (45)

- Fusion (58)

- Grid (66)

- High-Performance Computing (94)

- Hydropower (11)

- Irradiation (3)

- Isotopes (57)

- ITER (7)

- Machine Learning (51)

- Materials Science (147)

- Mathematics (10)

- Mercury (12)

- Microelectronics (4)

- Microscopy (51)

- Molten Salt (9)

- Nanotechnology (60)

- National Security (73)

- Net Zero (14)

- Neutron Science (138)

- Nuclear Energy (111)

- Partnerships (51)

- Physics (64)

- Polymers (33)

- Quantum Computing (37)

- Quantum Science (72)

- Renewable Energy (2)

- Security (25)

- Simulation (52)

- Software (1)

- Space Exploration (25)

- Statistics (3)

- Summit (60)

- Sustainable Energy (130)

- Transformational Challenge Reactor (7)

- Transportation (99)

Media Contacts

Distinguished materials scientist Takeshi Egami has spent his career revealing the complex atomic structure of metallic glass and other liquids — sometimes sharing theories with initially resistant minds in the scientific community.

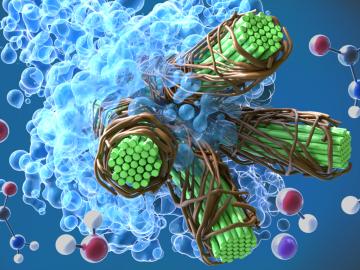

A team led by scientists at ORNL identified and demonstrated a method to process a plant-based material called nanocellulose that reduced energy needs by a whopping 21%, using simulations on the lab’s supercomputers and follow-on analysis.

Flexcon Global has exclusively licensed two patented inventions to manufacture a self-healing barrier film from ORNL for research and development purposes. The film can be incorporated into vacuum insulation panels to increase the efficiency of buildings during retrofits. Under a cooperative research and development agreement that began in 2021, Flexcon and ORNL have been exploring the capabilities of the technology and fine-tuning its properties.

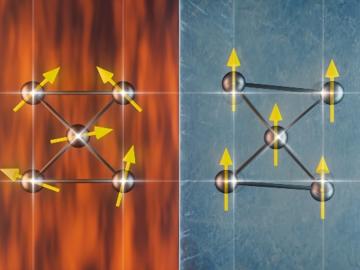

At ORNL, a group of scientists used neutron scattering techniques to investigate a relatively new functional material called a Weyl semimetal. These Weyl fermions move very quickly in a material and can carry electrical charge at room temperature. Scientists think that Weyl semimetals, if used in future electronics, could allow electricity to flow more efficiently and enable more energy-efficient computers and other electronic devices.

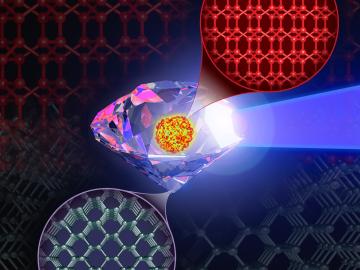

The world’s fastest supercomputer helped researchers simulate synthesizing a material harder and tougher than a diamond — or any other substance on Earth. The study used Frontier to predict the likeliest strategy to synthesize such a material, thought to exist so far only within the interiors of giant exoplanets, or planets beyond our solar system.

Brian Sanders is focused on impactful, multidisciplinary science at Oak Ridge National Laboratory, developing solutions for everything from improved imaging of plant-microbe interactions that influence ecosystem health to advancing new treatments for cancer and viral infections.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.

Building innovations from ORNL will be on display in Washington, D.C. on the National Mall June 7 to June 9, 2024, during the U.S. Department of Housing and Urban Development’s Innovation Housing Showcase. For the first time, ORNL’s real-time building evaluator was demonstrated outside of a laboratory setting and deployed for building construction.

ORNL researchers used electron-beam additive manufacturing to 3D-print the first complex, defect-free tungsten parts with complex geometries.