Filter News

Area of Research

- Advanced Manufacturing (6)

- Biology and Environment (15)

- Clean Energy (34)

- Computational Engineering (1)

- Computer Science (5)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (4)

- Fusion Energy (2)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials (79)

- Materials Characterization (1)

- Materials for Computing (15)

- Materials Under Extremes (1)

- National Security (8)

- Neutron Science (27)

- Nuclear Science and Technology (7)

- Supercomputing (34)

- Transportation Systems (1)

News Topics

- (-) Big Data (53)

- (-) Materials Science (139)

- (-) Space Exploration (25)

- 3-D Printing/Advanced Manufacturing (120)

- Advanced Reactors (34)

- Artificial Intelligence (91)

- Bioenergy (91)

- Biology (98)

- Biomedical (58)

- Biotechnology (22)

- Buildings (57)

- Chemical Sciences (63)

- Clean Water (29)

- Climate Change (99)

- Composites (26)

- Computer Science (187)

- Coronavirus (46)

- Critical Materials (25)

- Cybersecurity (35)

- Decarbonization (79)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (108)

- Environment (194)

- Exascale Computing (37)

- Fossil Energy (5)

- Frontier (42)

- Fusion (54)

- Grid (62)

- High-Performance Computing (84)

- Hydropower (11)

- Irradiation (3)

- Isotopes (53)

- ITER (7)

- Machine Learning (47)

- Materials (143)

- Mathematics (7)

- Mercury (12)

- Microelectronics (3)

- Microscopy (51)

- Molten Salt (8)

- Nanotechnology (60)

- National Security (61)

- Net Zero (13)

- Neutron Science (131)

- Nuclear Energy (107)

- Partnerships (43)

- Physics (61)

- Polymers (33)

- Quantum Computing (34)

- Quantum Science (69)

- Renewable Energy (2)

- Security (24)

- Simulation (47)

- Software (1)

- Statistics (3)

- Summit (57)

- Sustainable Energy (125)

- Transformational Challenge Reactor (7)

- Transportation (97)

Media Contacts

If humankind reaches Mars this century, an Oak Ridge National Laboratory-developed experiment testing advanced materials for spacecraft may play a key role.

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

The type of vehicle that will carry people to the Red Planet is shaping up to be “like a two-story house you’re trying to land on another planet.

Quanex Building Products has signed a non-exclusive agreement to license a method to produce insulating material from ORNL. The low-cost material can be used as an additive to increase thermal insulation performance and improve energy efficiency when applied to a variety of building products.

In collaboration with the Department of Veterans Affairs, a team at Oak Ridge National Laboratory has expanded a VA-developed predictive computing model to identify veterans at risk of suicide and sped it up to run 300 times faster, a gain that could profoundly affect the VA’s ability to reach susceptible veterans quickly.

Researchers at Oak Ridge National Laboratory proved that a certain class of ionic liquids, when mixed with commercially available oils, can make gears run more efficiently with less noise and better durability.

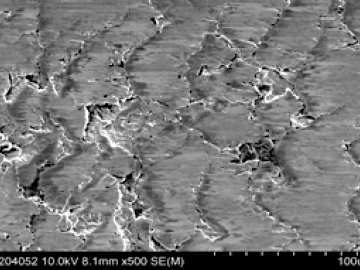

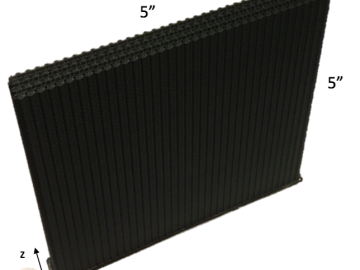

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

More than 6,000 veterans died by suicide in 2016, and from 2005 to 2016, the rate of veteran suicides in the United States increased by more than 25 percent.

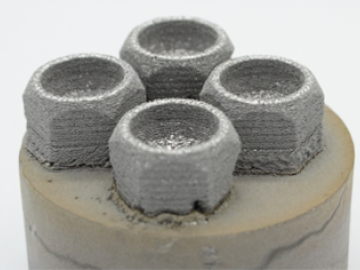

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

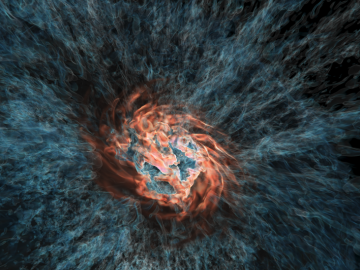

Using the Titan supercomputer at Oak Ridge National Laboratory, a team of astrophysicists created a set of galactic wind simulations of the highest resolution ever performed. The simulations will allow researchers to gather and interpret more accurate, detailed data that elucidates how galactic winds affect the formation and evolution of galaxies.