Filter News

Area of Research

News Topics

- (-) Composites (35)

- (-) Isotopes (62)

- (-) Polymers (35)

- 3-D Printing/Advanced Manufacturing (146)

- Advanced Reactors (40)

- Artificial Intelligence (131)

- Big Data (79)

- Bioenergy (112)

- Biology (128)

- Biomedical (73)

- Biotechnology (39)

- Buildings (74)

- Chemical Sciences (86)

- Clean Water (33)

- Computer Science (226)

- Coronavirus (48)

- Critical Materials (29)

- Cybersecurity (35)

- Education (5)

- Element Discovery (1)

- Emergency (4)

- Energy Storage (114)

- Environment (218)

- Exascale Computing (67)

- Fossil Energy (8)

- Frontier (64)

- Fusion (66)

- Grid (74)

- High-Performance Computing (130)

- Hydropower (12)

- Irradiation (3)

- ITER (9)

- Machine Learning (68)

- Materials (157)

- Materials Science (158)

- Mathematics (12)

- Mercury (12)

- Microelectronics (4)

- Microscopy (56)

- Molten Salt (10)

- Nanotechnology (64)

- National Security (86)

- Neutron Science (171)

- Nuclear Energy (122)

- Partnerships (68)

- Physics (69)

- Quantum Computing (53)

- Quantum Science (92)

- Security (31)

- Simulation (65)

- Software (1)

- Space Exploration (26)

- Statistics (4)

- Summit (71)

- Transportation (103)

Media Contacts

Oak Ridge National Laboratory researchers have discovered a better way to separate actinium-227, a rare isotope essential for an FDA-approved cancer treatment.

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

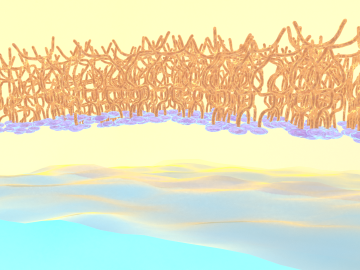

Biological membranes, such as the “walls” of most types of living cells, primarily consist of a double layer of lipids, or “lipid bilayer,” that forms the structure, and a variety of embedded and attached proteins with highly specialized functions, including proteins that rapidly and selectively transport ions and molecules in and out of the cell.

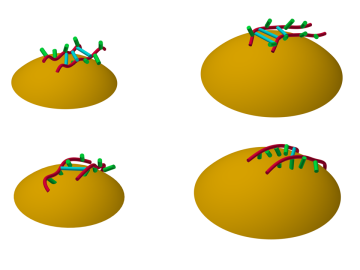

OAK RIDGE, Tenn., Feb. 27, 2020 — Researchers at Oak Ridge National Laboratory and the University of Tennessee achieved a rare look at the inner workings of polymer self-assembly at an oil-water interface to advance materials for neuromorphic computing and bio-inspired technologies.

ORNL and The University of Toledo have entered into a memorandum of understanding for collaborative research.

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

A team of researchers at Oak Ridge National Laboratory have demonstrated that designed synthetic polymers can serve as a high-performance binding material for next-generation lithium-ion batteries.

Vera Bocharova at the Department of Energy’s Oak Ridge National Laboratory investigates the structure and dynamics of soft materials.

OAK RIDGE, Tenn., Jan. 31, 2019—A new electron microscopy technique that detects the subtle changes in the weight of proteins at the nanoscale—while keeping the sample intact—could open a new pathway for deeper, more comprehensive studies of the basic building blocks of life.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.