Filter News

Area of Research

News Type

Media Contacts

The Department of Energy’s Oak Ridge National Laboratory and Momentum Technologies have signed a non-exclusive licensing agreement for an ORNL process designed to recover rare earth magnets from used computer hard drives. The patent-pending process developed as par...

A 3D printed trim-and-drill tool, developed by researchers at the Department of Energy’s Oak Ridge National Laboratory to be evaluated at The Boeing Company, has received the title of largest solid 3D printed item by Guinness World Records. ORNL printed the...

Six small companies will tap the expertise of the Department of Energy’s Oak Ridge National Laboratory to move their manufacturing, fuel cell, geothermal and vehicle technologies closer to the marketplace. The businesses are among 43 selected to participate in the ...

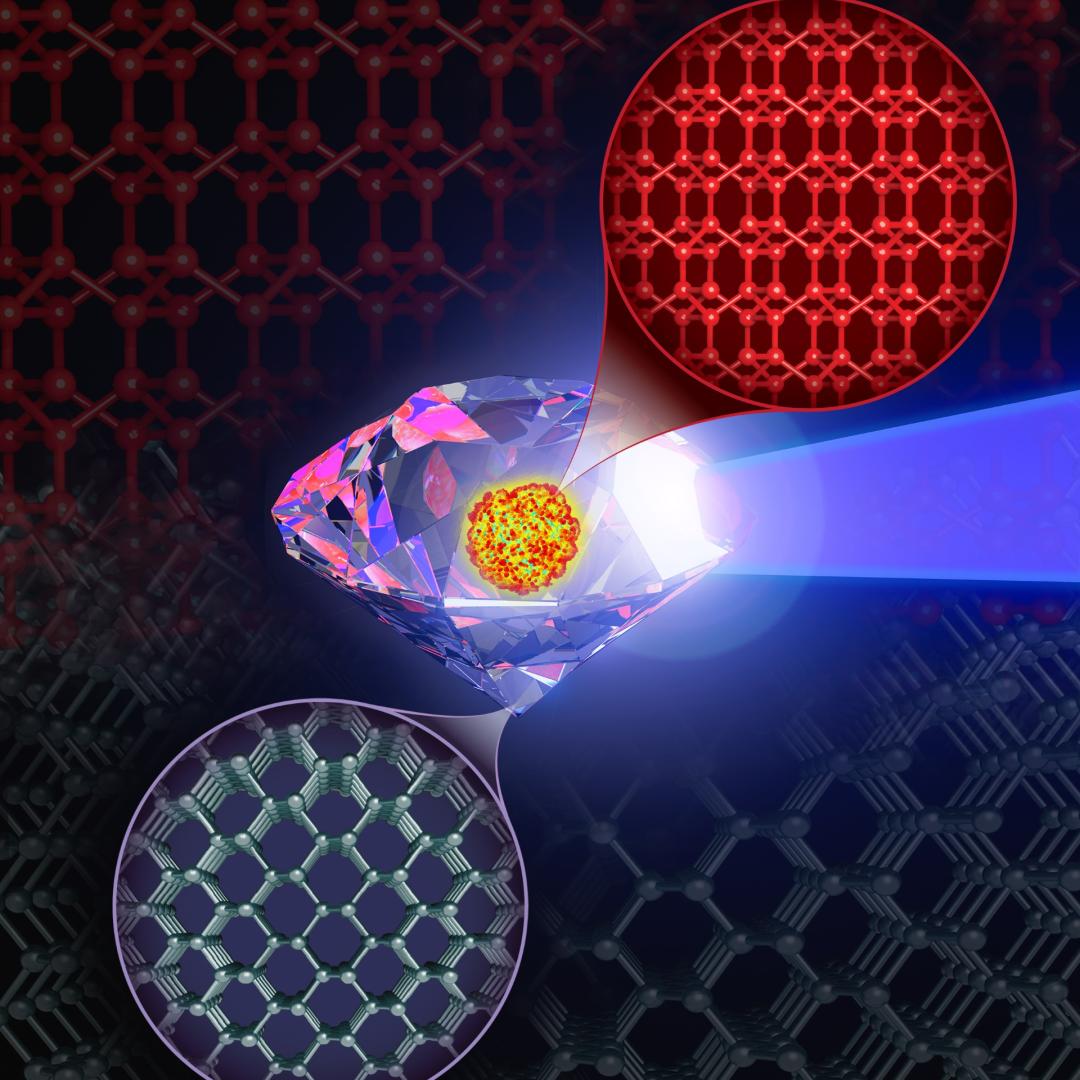

The US Department of Energy announced today that it will invest $16 million over the next four years to accelerate the design of new materials through use of supercomputers.

A process developed at Oak Ridge National Laboratory for large-scale recovery of rare earth magnets from used computer hard drives will undergo industrial testing under a new agreement between Oddello Industries LLC and ORNL, as part of the Department of Energy’s Crit...

The 2016 Billion Ton Report, jointly released by the U.S. Department of Energy and Oak Ridge National Laboratory, concludes that the United States has the potential to sustainably produce at least 1 billion dry tons of nonfood biomass resources annually by 2040.

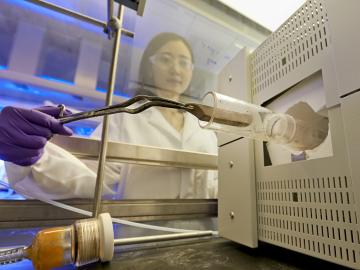

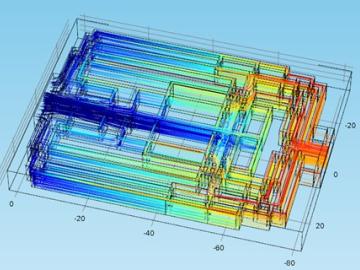

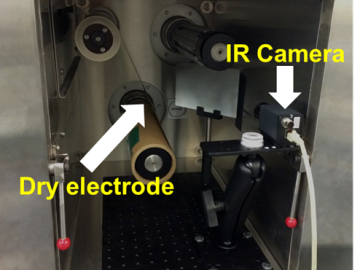

Production run spot checks of materials for lithium-ion batteries and fuel cells could be a thing of the past because of a process developed at Oak Ridge National Laboratory. The infrared/thermal nondestructive evaluation technique invented by a team led by David Wood examines key parameters such as porosity and thickness of the coating in real time without destroying product.