Filter News

Area of Research

- Advanced Manufacturing (4)

- Biology and Environment (10)

- Clean Energy (43)

- Climate and Environmental Systems (2)

- Fusion and Fission (1)

- Fusion Energy (1)

- Materials (23)

- Materials for Computing (2)

- National Security (2)

- Neutron Science (10)

- Nuclear Science and Technology (7)

- Quantum information Science (3)

- Supercomputing (20)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (28)

- (-) Bioenergy (13)

- (-) Environment (29)

- (-) Frontier (1)

- (-) Molten Salt (2)

- (-) Nanotechnology (17)

- (-) Polymers (7)

- (-) Quantum Science (14)

- Advanced Reactors (14)

- Artificial Intelligence (8)

- Big Data (11)

- Biology (5)

- Biomedical (21)

- Biotechnology (2)

- Buildings (1)

- Chemical Sciences (5)

- Clean Water (2)

- Climate Change (10)

- Composites (1)

- Computer Science (39)

- Coronavirus (23)

- Critical Materials (3)

- Cybersecurity (4)

- Decarbonization (1)

- Energy Storage (21)

- Exascale Computing (3)

- Fusion (14)

- Grid (7)

- High-Performance Computing (3)

- Isotopes (8)

- Machine Learning (8)

- Materials (2)

- Materials Science (38)

- Mathematics (2)

- Mercury (1)

- Microscopy (8)

- National Security (2)

- Neutron Science (31)

- Nuclear Energy (32)

- Physics (13)

- Security (3)

- Space Exploration (2)

- Summit (17)

- Sustainable Energy (24)

- Transformational Challenge Reactor (5)

- Transportation (15)

Media Contacts

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

An international team of scientists found that rules governing plant growth hold true even at the edges of the world in the Arctic tundra.

Oak Ridge National Laboratory researchers have developed a thin film, highly conductive solid-state electrolyte made of a polymer and ceramic-based composite for lithium metal batteries.

For the second year in a row, a team from the Department of Energy’s Oak Ridge and Los Alamos national laboratories led a demonstration hosted by EPB, a community-based utility and telecommunications company serving Chattanooga, Tennessee.

Researchers at the Department of Energy’s Oak Ridge National Laboratory are refining their design of a 3D-printed nuclear reactor core, scaling up the additive manufacturing process necessary to build it, and developing methods

In the 1960s, Oak Ridge National Laboratory's four-year Molten Salt Reactor Experiment tested the viability of liquid fuel reactors for commercial power generation. Results from that historic experiment recently became the basis for the first-ever molten salt reactor benchmark.

OAK RIDGE, Tenn., May 5, 2020 — By 2050, the United States will likely be exposed to a larger number of extreme climate events, including more frequent heat waves, longer droughts and more intense floods, which can lead to greater risks for human health, ecosystem stability and regional economies.

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

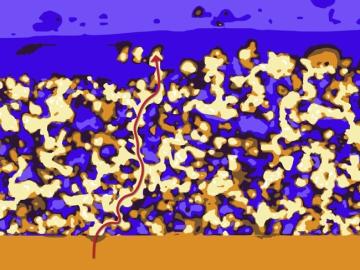

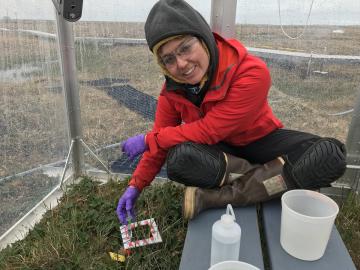

While some of her earth system modeling colleagues at ORNL face challenges such as processor allocation or debugging code, Verity Salmon prepares for mosquito swarms and the possibility of grizzly bears.

In the early 2000s, high-performance computing experts repurposed GPUs — common video game console components used to speed up image rendering and other time-consuming tasks